The rotary indexing system is a sophisticated and highly efficient mechanism used in various industries to streamline production processes. This automation technology enables the precise movement and positioning of workpieces at predetermined intervals, allowing assembly workstations to perform specific tasks with exceptional accuracy.

In this article, we will explore the concept of the rotary indexing system and its diverse applications in assembly workstations across different industries.

Understanding the Rotary Indexing System

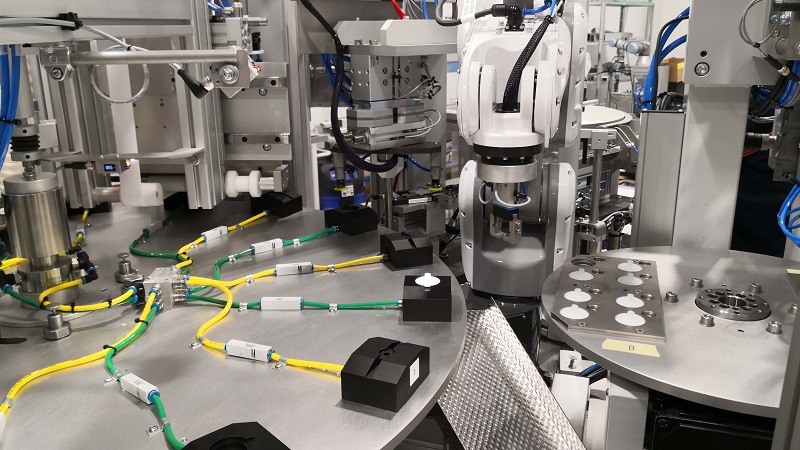

The rotary indexing system is a type of automation technology that facilitates the rotational movement of workpieces within a manufacturing or assembly line. It operates on the principle of indexing, which involves moving the workpiece from one station to the next in fixed angular increments or positions. The rotary motion can be continuous or step-by-step, depending on the specific production requirements.

Key Components of a Rotary Indexing System

Indexing Table:

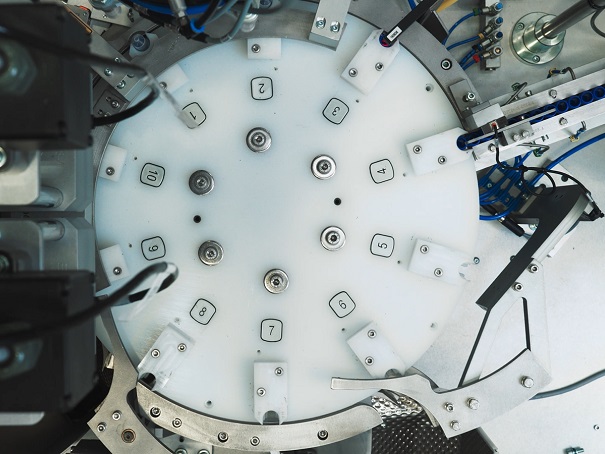

At the heart of the rotary indexing system lies the indexing table, also known as a turntable. This table is designed to hold and rotate the workpiece, ensuring precise positioning at each workstation. The indexing table is driven by a precise motor or mechanical mechanism, ensuring smooth and accurate movement.

Indexing Drive:

The indexing drive is a critical component that controls the rotation of the indexing table. It dictates the speed and accuracy of the rotary motion, ensuring proper alignment with the assembly workstations.

Workstations:

Surrounding the indexing table are multiple workstations, each equipped with specialised tools, robots, or machinery. These workstations perform specific assembly tasks on the workpiece as it rotates to each station.

Applications of Rotary Indexing System in Assembly Workstations

Automotive Industry:

The automotive industry heavily relies on rotary indexing systems for efficient assembly processes. In engine assembly, the rotary indexing system allows precise placement of engine components, such as pistons, connecting rods, and crankshafts, at various stages. This ensures accurate alignment and optimal performance of the finished engine.

Electronics and Electrical Appliances:

The electronics industry heavily relies on rotary indexing systems for the assembly of circuit boards, semiconductor devices, and consumer electronics. The system facilitates the soldering, gluing, and mounting of parts with utmost precision and repeatability.

Medical Devices:

The manufacturing of medical devices, such as pacemakers, implants, and diagnostic equipment, demands utmost precision. Rotary indexing systems play a crucial role in assembling these intricate devices, guaranteeing accuracy and compliance with stringent quality standards. The indexing mechanism ensures that each workpiece moves through the stations with minimal human intervention, reducing the risk of contamination and increasing production rates.

Packaging:

In the packaging sector, rotary indexing systems are used to assemble and package various products. From filling, capping and labelling bottles to assembling complex packaging structures, the system ensures consistent and efficient packaging operations.

Aerospace:

In aerospace manufacturing, the rotary indexing system aids in assembling critical components of aircraft, missiles, and satellites. This technology facilitates intricate assembly processes, meeting aerospace engineering standards with precision.

Consumer Goods:

Various consumer goods, such as watches, toys, and small appliances, benefit from the accuracy and efficiency of rotary indexing systems. These systems enable the precise assembly of components, resulting in high-quality and reliable products.

Food and Beverage Industry:

In the food and beverage industry, rotary indexing systems are employed for filling, sealing, and labelling containers. This ensures consistent and hygienic packaging of food and beverage products, even at high production speeds.

Read more:

- Unravelling the Efficiency of Automated Rotary Assembly Lines

- Semi-Automated vs Fully Automated: Which one is right for your manufacturing process?

- How do Industrial Automation Expectations Differ from Reality

- Automation is the Catalyst for Factory Transition

Application studies:

SED Tube and Filter Assembly Machine

SED Tube and Filter Assembly Machine

Advantages of Rotary Indexing System in Assembly Workstations

- Enhanced Precision: The rotary indexing system offers exceptional accuracy, reducing errors and improving the quality of the assembled products.

- Increased Productivity: By eliminating manual handling and optimizing production flow, the rotary indexing system enhances overall productivity and output.

- Flexibility: The system can be easily adapted to accommodate different product sizes and assembly tasks, providing versatility in manufacturing operations.

- Cost Efficiency: With reduced labour requirements and improved production rates, the rotary indexing system contributes to cost savings over time.

- Space Optimization: The compact design of the rotary indexing system optimizes floor space, making it suitable for assembly workstations with limited areas.

Conclusion

The rotary indexing system has proven to be a game-changer in assembly workstations, providing unparalleled precision, efficiency, and flexibility. Its applications span across diverse industries, from automotive and electronics to medical devices and aerospace. By streamlining production processes and ensuring consistent quality, the rotary indexing system continues to play a pivotal role in advancing manufacturing efficiency and meeting the demands of the modern market.