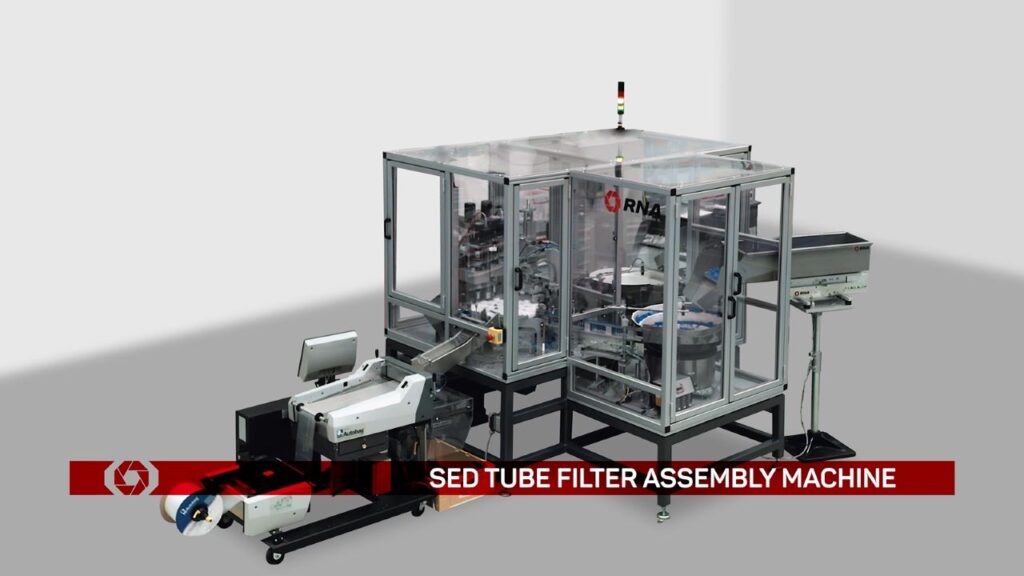

Solution

In a cycle time of 4 seconds, the 4-position cam indexing assembly machine assembles two component parts, monitors them for quality and sends them to a bagging machine for packing.

Station 1 – Load filters

At station 1, filters are loaded by a vibratory bowl feeder into a fixture on the rotary indexing table and then are transferred to the second station.

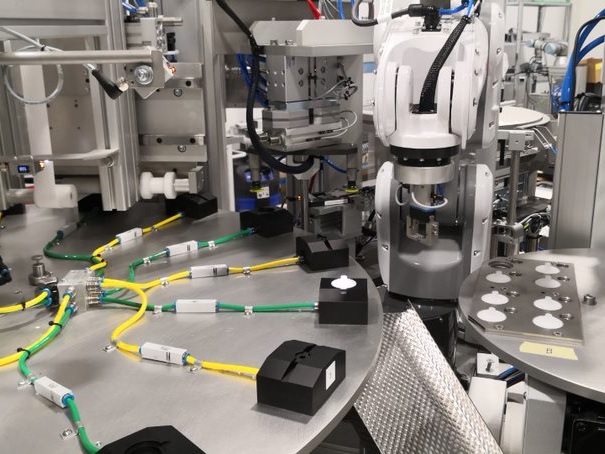

Station 2 – Load sediment tubes

Sediment tubes are loaded in bulk to a vibratory bowl feeder. The bowl feeder orientates the tubes and feeds them to a location plate to accurately locate the parts for picking. The tubes are transferred from the location plate into the rotary table nest (right above the filters) by two pneumatically actuated twin-headed rotary pick and place units fitted with pneumatic grippers.

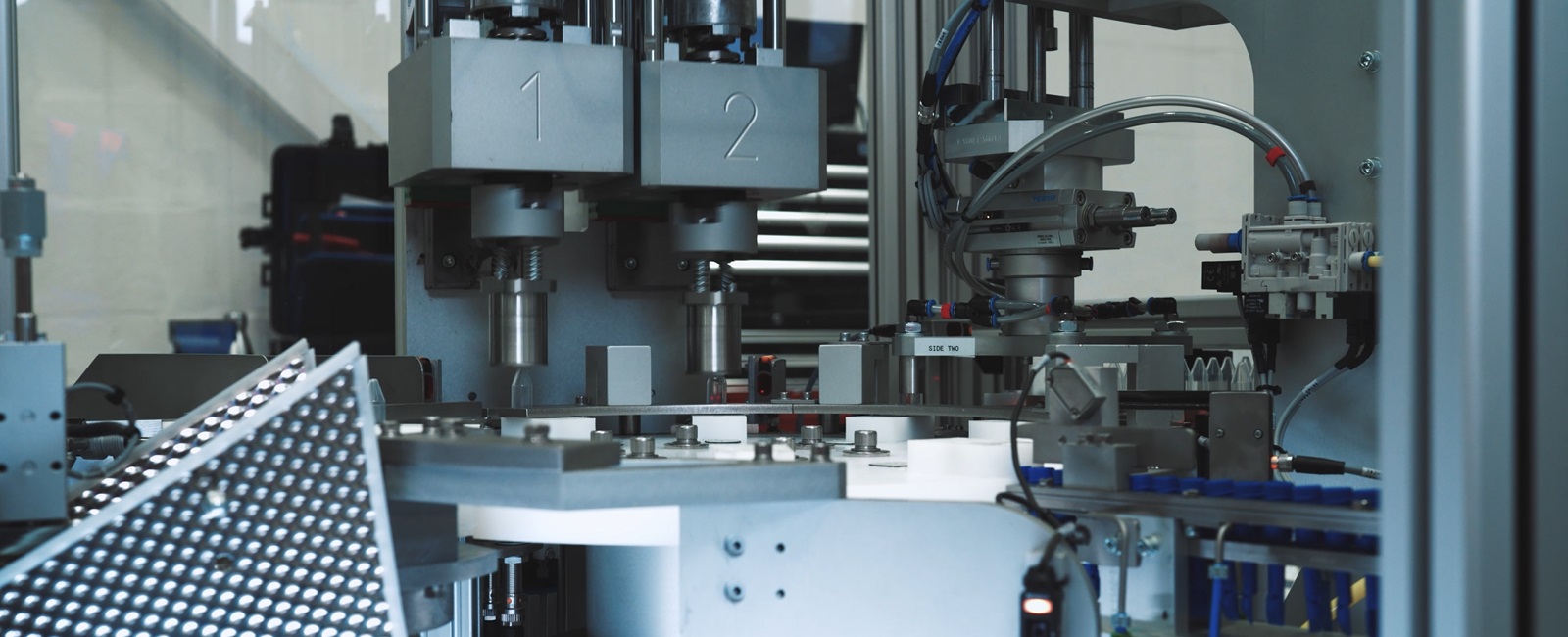

Station 3 – Screwdriver station

The two component parts now moves on to station 3 where two electronic screwdrivers await the parts here. The screwdrivers screw and tighten the filters and tubes to form the assembled component parts.

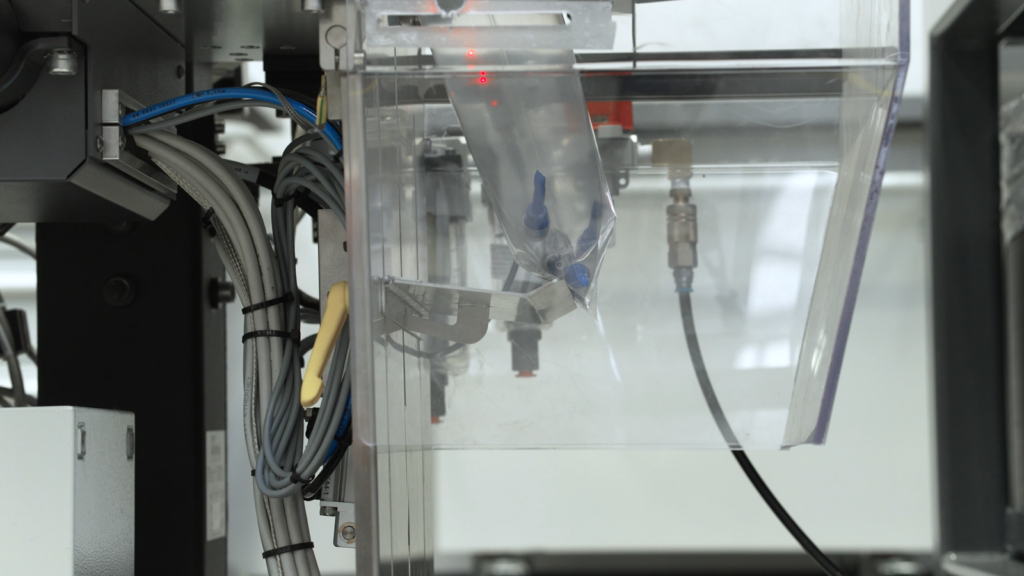

Counting and Bagging Machine

The quality control device checks and discharges the GOOD assembled parts via a chute. And the pneumatically operated bomb door escapement collects and releases 60 component parts at a time to a pre-opened bag, then sealed and dispensed into a container.

Vibratory Bowl Feeder for Filters

Vibratory Bowl Feeder for Filters Vibratory Bowl Feeder for SED Tubes

Vibratory Bowl Feeder for SED Tubes Screw Assembly Station

Screw Assembly Station Counting and Bagging Machine

Counting and Bagging Machine