Centrifugal Feeders

RNA offers a full range of tooled centrifugal feeders. In association with industry leading suppliers, RNA offers a full range of centrifugal feeder solutions.

Downloads

RNA OFFER

Standard feedersCustom, customer-specific solutions

Suitable for Industrial, Pharmaceuticals, Medicals, Food, Packaging

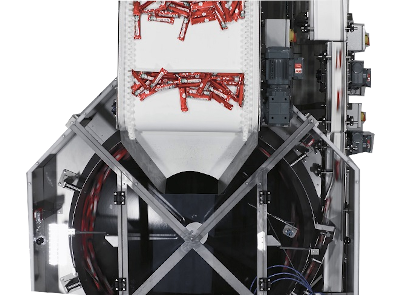

RNA Standard Range High-speed centrifugal feeding system for Wrapped Chocolate Bars, Cereal Bars, Protein Bars, Energy Bars, and Fruit Bars

What is a centrifugal feeder?

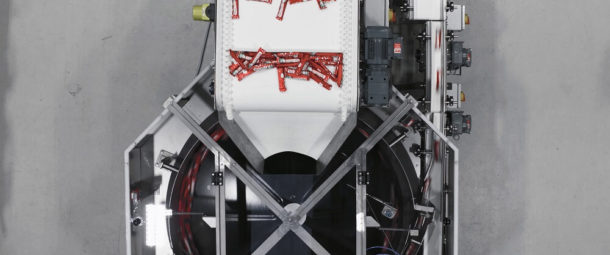

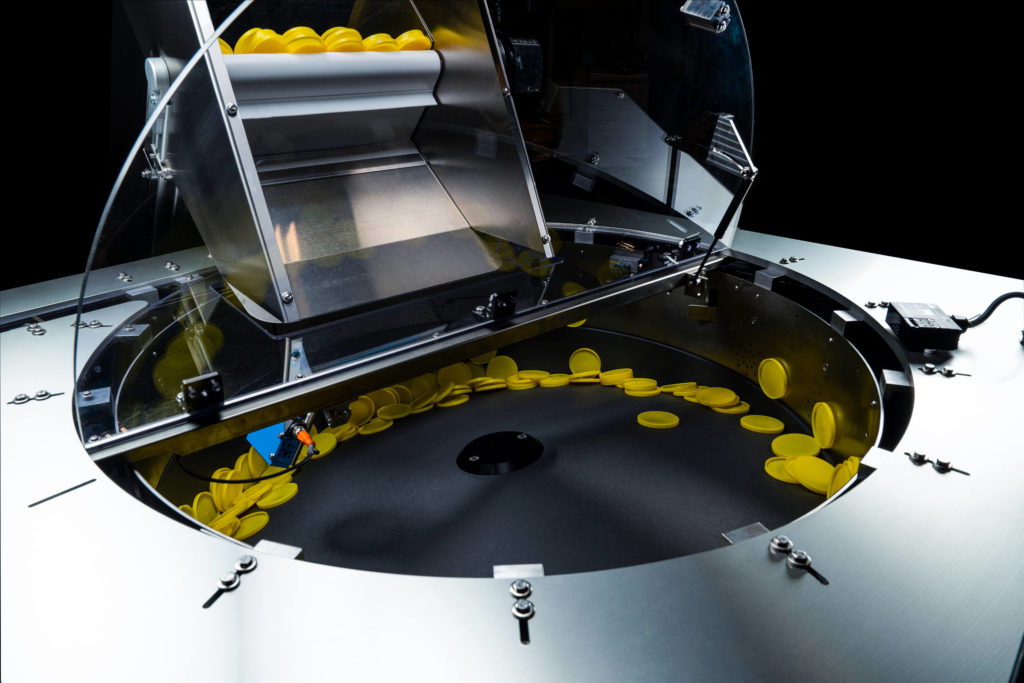

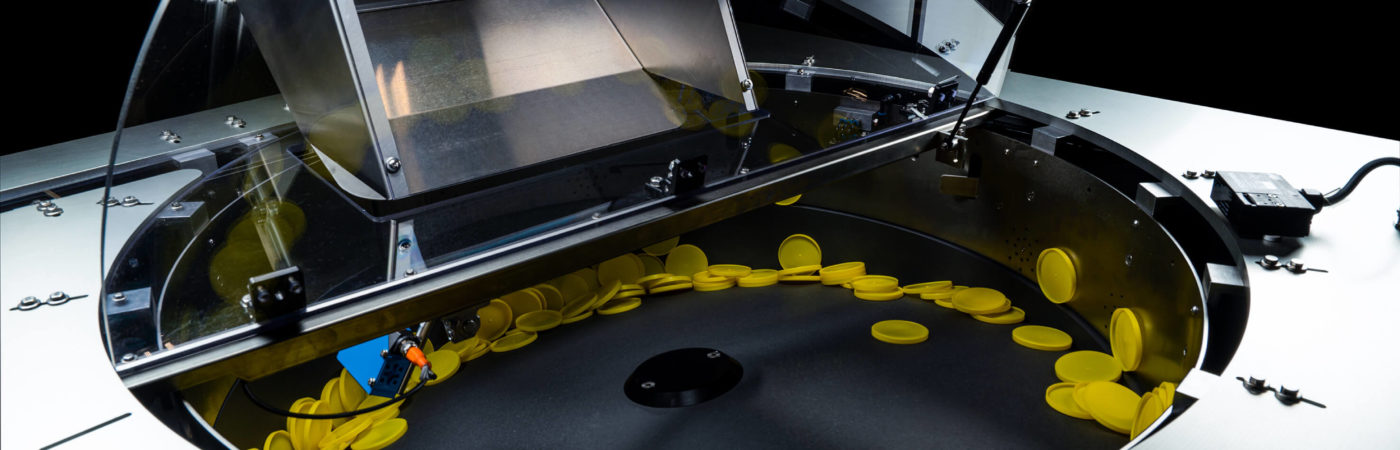

A centrifugal feeder is a feeding unit that can be used in feeding even the most awkward shaped components at high efficiency and speed whilst reducing the risk of damaging the component. The centrifugal feeder consists of a conical central driven rotor surrounded by a circular bowl wall. The feeder spins and separates component parts utilising rotary force and the parts revolve with high speed and are pulled to the outside of the bowl.

Centrifugal feeders are gentle on component parts due to low circulation and are best for high rate applications.

Custom Centrifugal Feeder Systems

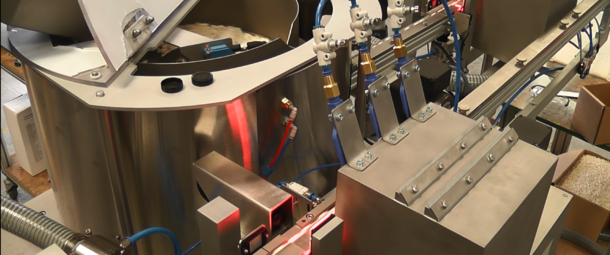

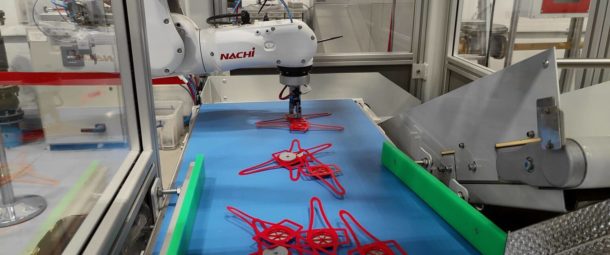

RNA Automation provides custom centrifugal feeder systems to handle the entire production line including handling, transporting via downstream conveyor belt system and packing operations. Examples of the packing capabilities are capping, labelling, cartoning and flow wrapping the components and products.

How does a centrifugal feeder work?

The centrifugal feeder contains a centre disc mounted on an angle and a horizontally mounted feeding bowl. Both parts can rotate independently at variable speeds. The RNA centrifugal feeder can handle up to 3,000 parts per minute. Handled components are usually brought to the raised edge of the centrifugal feeder disc.

In which industries is the centrifugal feeder used?

Centrifugal feeders are used by many industries, including pharmaceutical & healthcare, food, plastics as well as Fast-Moving Consumable Goods (FMCG).

Applications of centrifugal feeders

We would recommend our centrifugal feeder system solutions to businesses in manufacturing, food, pharmaceutical and medical industries where small and awkwardly shaped components need to be handled at high speed. View the range of our case studies to find out more about how we helped various businesses with the implementation and integration of centrifugal feeding systems.

Benefits of centrifugal feeders

Benefits of centrifugal feeders include high speed of part processing. Centrifugal feeders are a good alternative to vibratory bowl feeders that can handle up to 3,000 parts per minute whilst also sorting and orientating components of different sizes and shapes. The simple design, high reliability and low maintenance make this solution very cost-effective.

Applications

Downloads

Contact

Send your message to a member of our team

Read our Privacy Policy to learn how we manage and protect your submitted information.