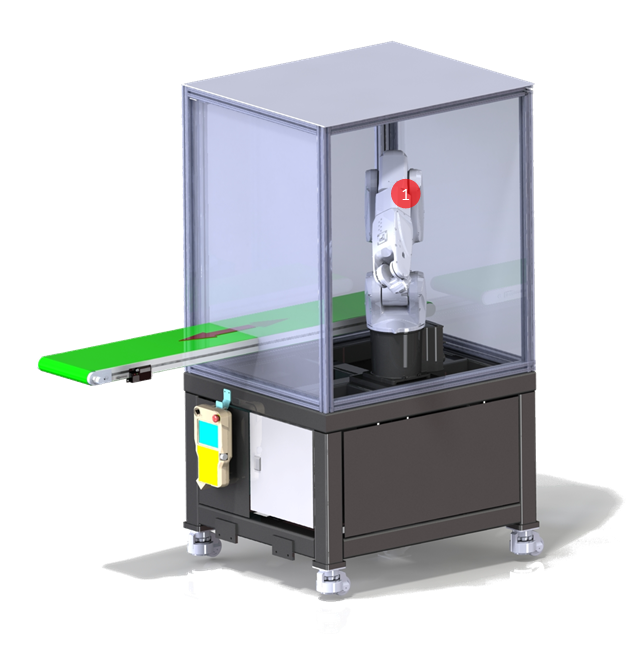

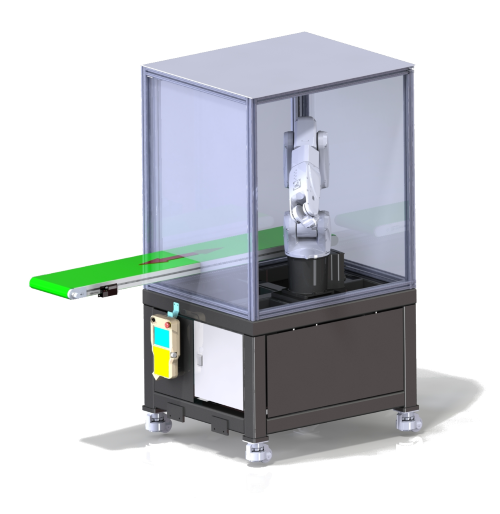

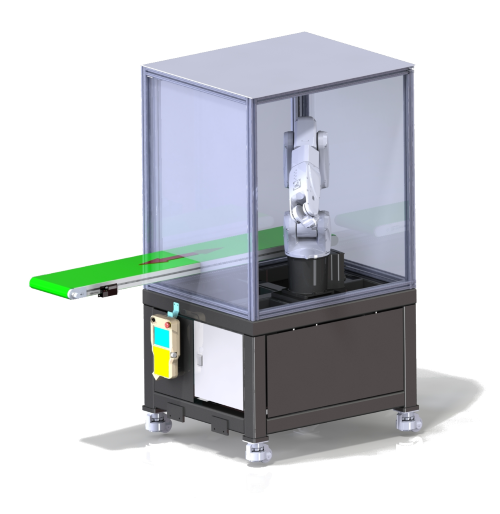

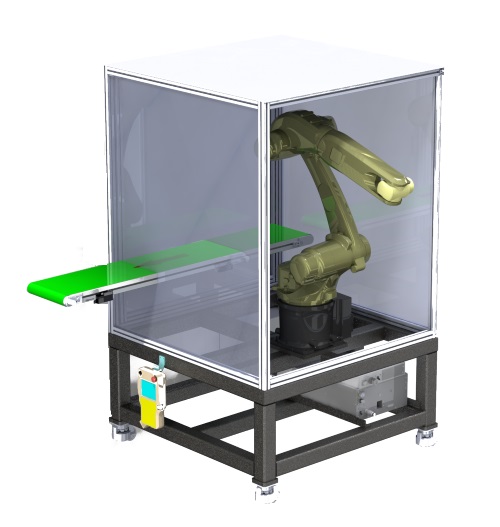

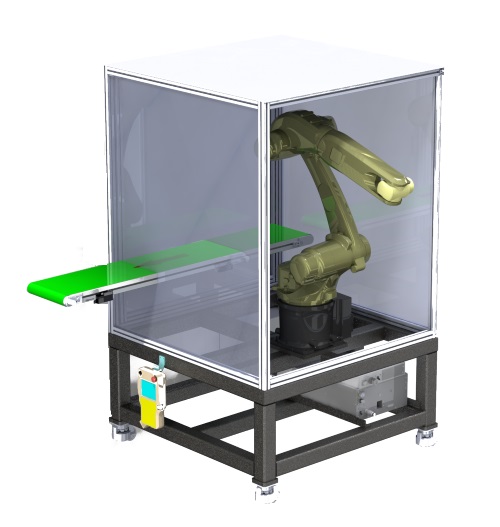

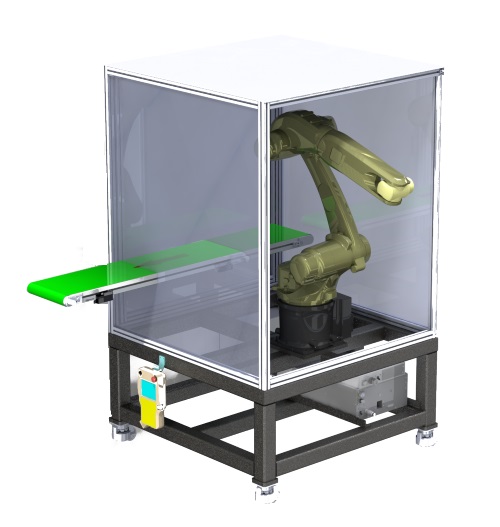

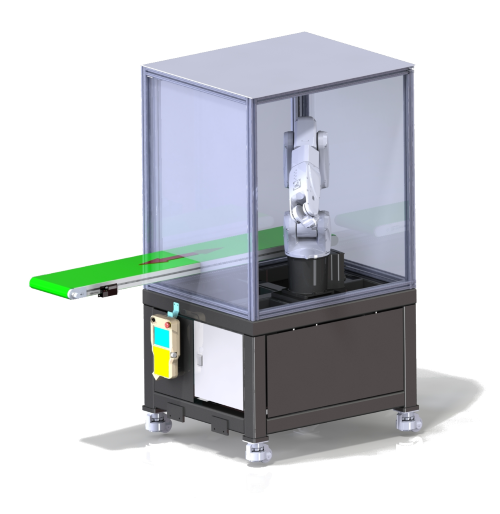

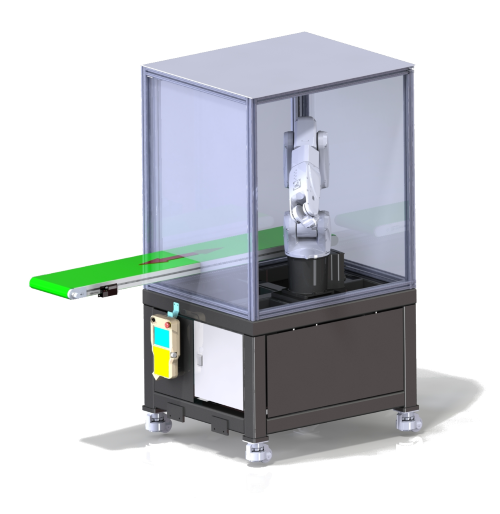

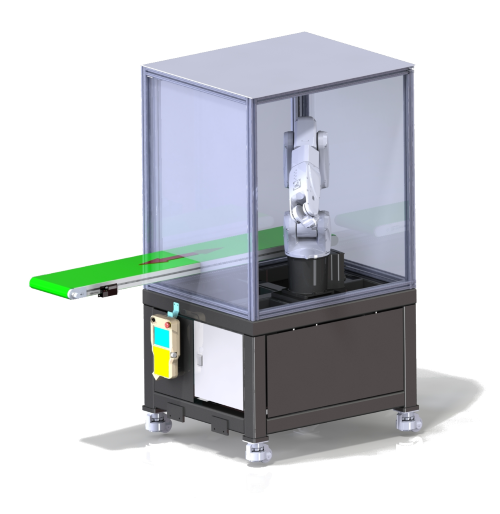

RNA’s VariTend™ presents a precise flexible robotic handling solution for injection moulding and machine tending applications, coupled with an integrated out-feed compact conveyor system.

to suit your applications

50T - 100T | 100T - 150T | 150T - 200T | |

|   |   | |

Specification | |||

Dimensions | 1000 x 865 x 1824 mm | 1000 x 865 x 1824 mm | 1200 x 1215 x 2014 mm |

Robot | Nachi | Nachi | Nachi |

Euromap 67 and 73 interfaces (or equivalent interfaces) mounted onto the frame | ||

Upper arm services: 2 x monitored vacuum and 1 x un-monitored grip | ||

Interlocked safety guarding, mounted on a fabricated frame fitted with castors | ||

Frame to IMM fixing brackets | ||

Indexing conveyor | ||

External programming pendant | ||

Various length/width to suit your applications | ||

Requirements | The moulding machine must have the relevant Euromap or equivalent interfaces to connect to the cell | |

Mechnical Interface (included) | ||

Options | ■ Bespoke end or arm tooling | |

■ Vision system | ||

■ De-gating station | ||

Get in touch for any specialised options |

VariTend™ can be used to automate a variety of manufacturing processes, including:

Send your message to a member of our team

Read our Privacy Policy to learn how we manage and protect your submitted information.