Flexible Feeders

Flexible feeders are great at helping manufacturers accommodate product variants on the assembly line. RNA’s high performance flexible feeding systems deliver a complete solution for flexible part feeding.

Downloads

RNA OFFER

Standard feedersCustom, customer-specific solutions

Suitable for Industrial, Pharmaceuticals, Medicals

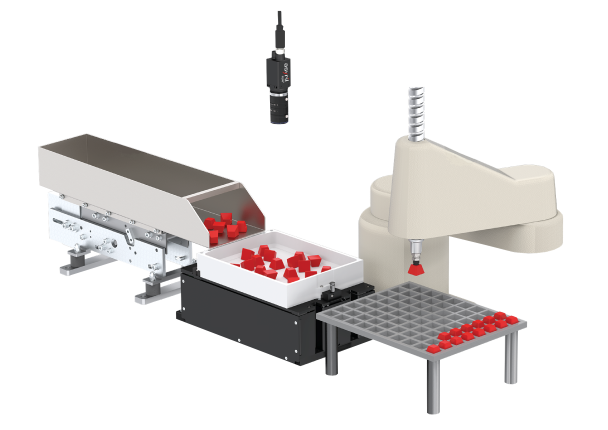

RNA Compact Modular Systems RNA provide standard and custom feeding systems.

What is Flexible Part Feeding?

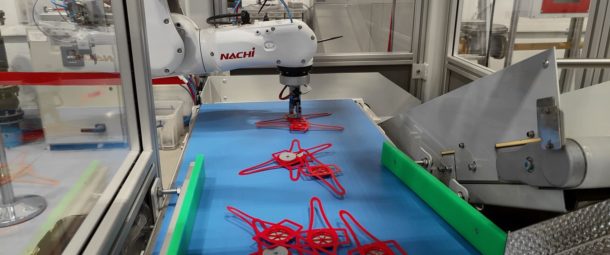

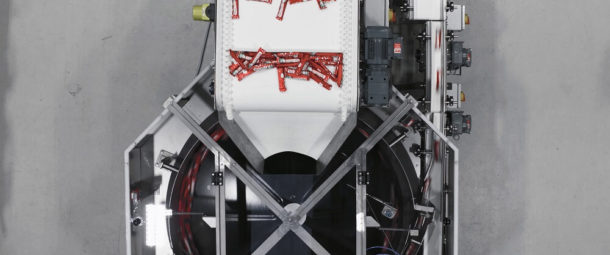

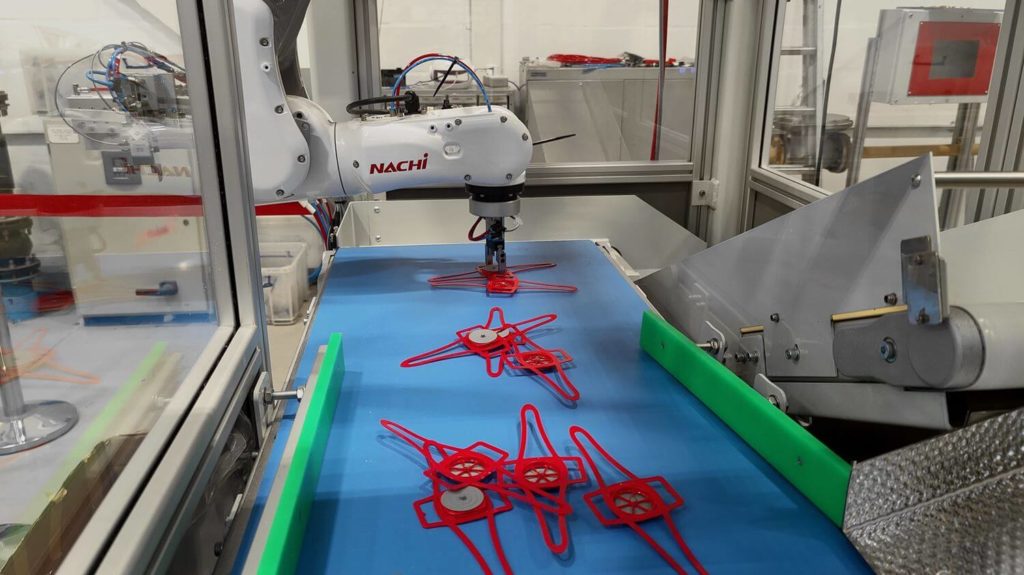

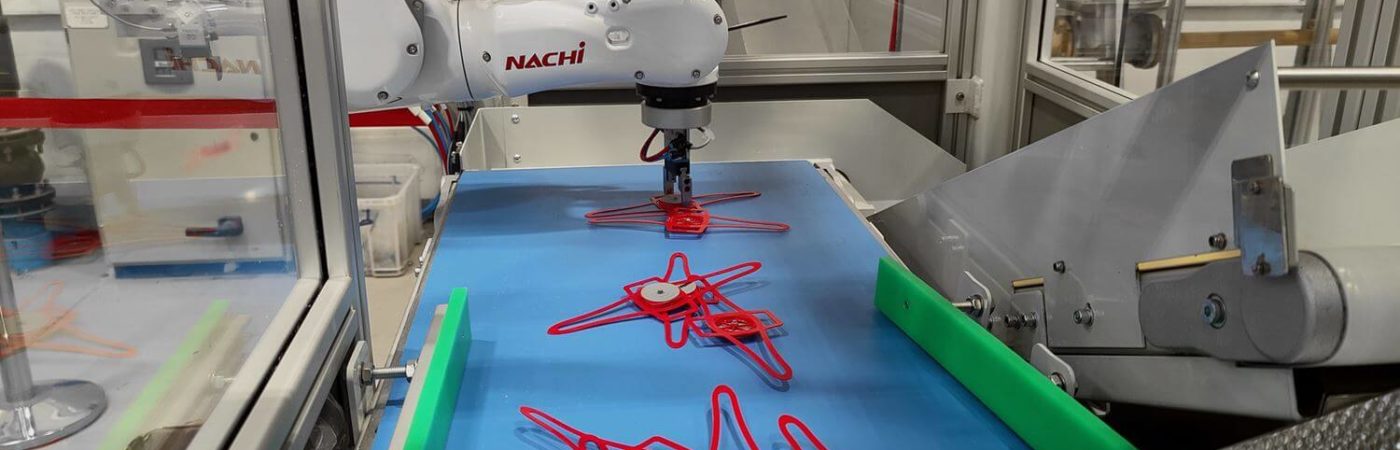

A flexible feeding system can be a system used to feed /load component parts into a manufacturing process. The best kind of intelligent flexible feeder system includes a feeder to handle and feed the part, a vision system to locate the part for the next process, and a robot. This type of system can overcome the high cost of traditional parts feeding by loading a wide variety of parts in various sizes, shapes and orientations.

The advantages of a flexible part feeder is that you can present many different parts into an assembly process through the same part feeding mechanism and let the vision system determine what parts to pick and how to pick them.

Forward thinking

Automation can be another key to significantly increased output, optimising both production and the allocation of skills within the business. RNA’s flexible feeders are renowned for requiring minimum human intervention, but it’s not necessarily about saving labour – more that staff can be deployed on more complex and productive tasks.

Flexible feeders offer quick payback on capital outlay: it’s possible to automate with lower capital costs but make the most of that investment as we’ve explored here. Despite the current cost of living crisis, the UK confectionery market is predicted to continue growing annually by 2.48% (CAGR 2022-2027)2.

It’s clear that innovation in flavour combinations and dietary needs are driving the sheer volume of confectionery now on offer – which in turn emphasises the overriding need for a feeding system offering flexibility, speed and simplicity, reliability and efficiency – and ultimately a rapid ROI and future proof technology.

Contact

Send your message to a member of our team

Read our Privacy Policy to learn how we manage and protect your submitted information.