Solution

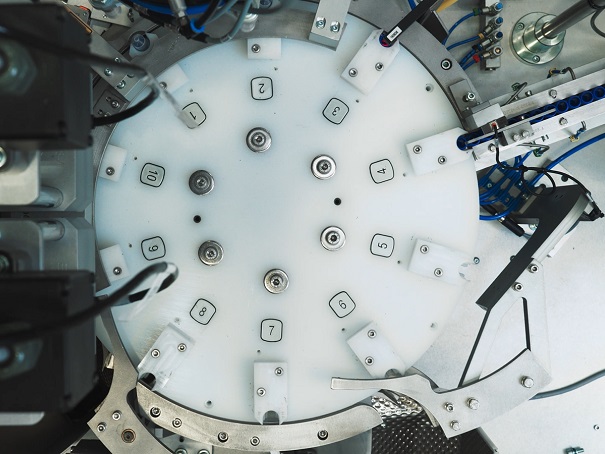

In a cycle time of 1.2 seconds, the 10-position cam indexing assembly machine fills and assembles two component parts, monitors them for quality and sends them to an automatic labelling system.

Station 1 – Vial loading in pairs

At station 1, Vials are loaded by vibratory bowl feeder into an empty pocket on the dial plate each time the machine plate indexes and then are transferred to the second station.

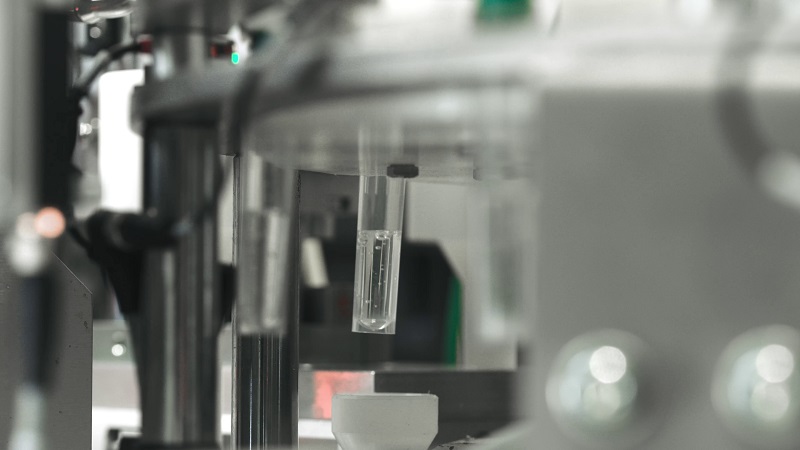

Station 2 – Twin head fill station

When 2 empty Vials are presented under station 2, the valves are activated to fill the vials. If one vail is missing, no filling take places and both pockets are identified as rejects.

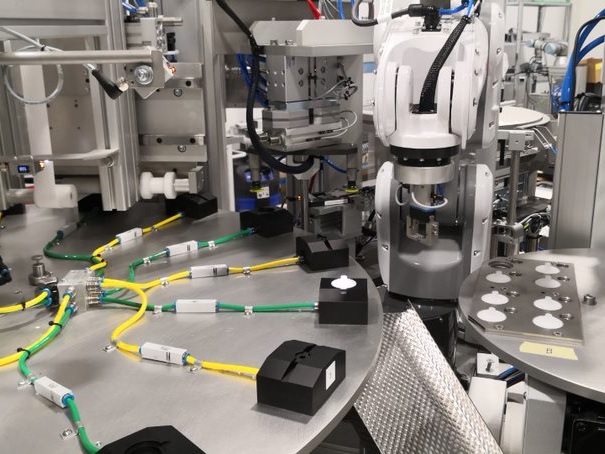

Station 3 – Cap loading in pairs

Caps are orientated and fed by the Cap bowl feeder from both lanes into the escapements. The escapement side shuttle to present 2 caps for the Pick & Place.

The caps are transferred into the rotary table nest (right above the filled vials) by two pneumatically actuated twin-headed rotary pick and place units fitted with pneumatic vacuum gripper.

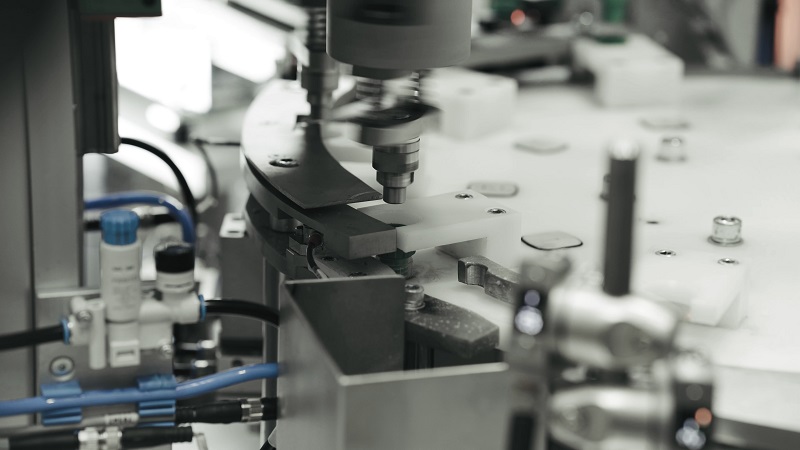

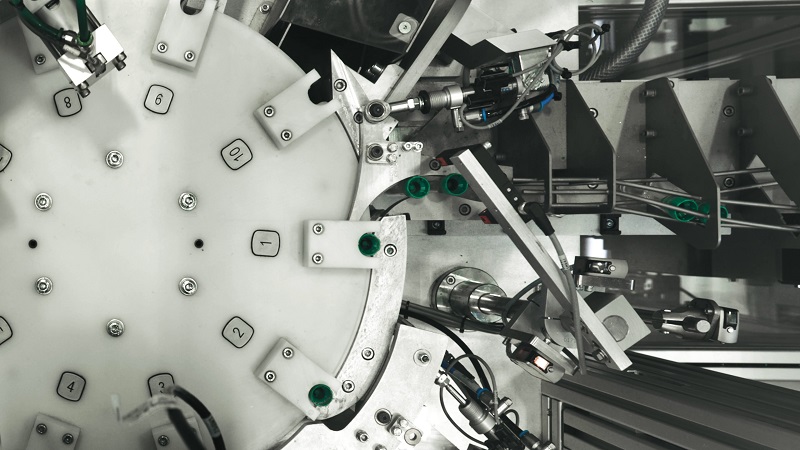

Station 4 – Twin head cap closing station

When 2 vials with loose caps are presented under station 4 two pneumatic cylinders advance the two screw heads. The screw heads screw and tighten the caps and vials to form the assembled component parts.

Station 5 – Divert to box & Unload to label machine station.

If the label machine is not running, the “divert to box” wiper on a pneumatic cylinder is positioned to wipe all good product off the dial plate onto a chute into a box.

If the label machine is running or parts are identified as reject, the “divert to box” wiper on a pneumatic cylinder is positioned to allow all parts to move through to the next position.

An “unload” wiper on a pneumatic cylinder is positioned to wipe all GOOD parts off the dial plate onto the exit track where the linear track transfers the assembled parts onto the labelling machine.

In the event of parts identified as reject, the “unload” wiper cylinder will remove the wiper and the parts will move through to a third fixed wiper that will drop the parts into the reject box.

Vial Loading into Machine

Vial Loading into Machine Filling Station

Filling Station Cap Loading into Machine

Cap Loading into Machine Cap Closing Station

Cap Closing Station Unload to Labelling Machine

Unload to Labelling Machine