Applications

Videos

Enquiry form

Robotic Clipping Systems

Semi-automated and Fully automated Clipping Machines

Downloads

Suitable for

Clipping ApplicationUltrasonic Welding Application

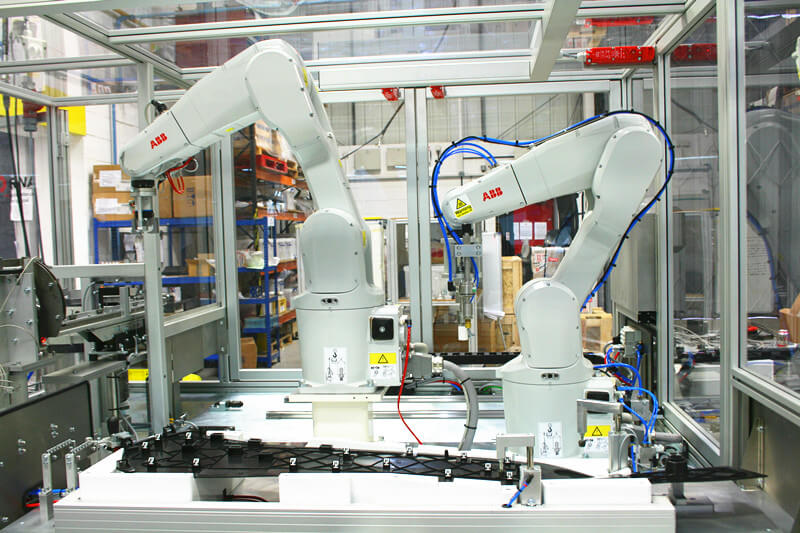

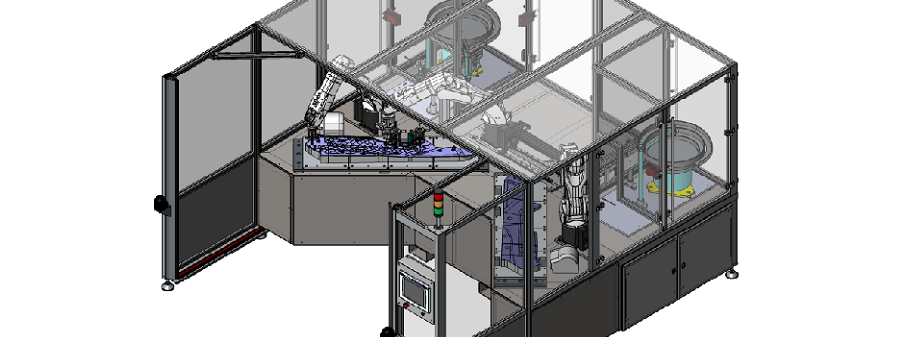

The clipping machine range includes semi-automated clipping cells and fully automated robot clipping machines. The poka-yoke design ensures proper clip assembly of automotive interior and exterior moulded components.

Clipping Application

- Single or Multi-Robot Cell

- Bowl feeder system(s)

- Full Poke Yoke for clip present

Ultrasonic Welding Application

- Single or Multi-Robot Cell

- Ultrasonic welding system

- Integrate welding in with the clipping operation

Key Benefits

1. Short payback

2. Great flexibility

3. Increased productivity

4. Compact design

5. High output

Applications

×

Machine Features

Downloads

- Machine Frame inclusive of base plate

- Machine Guarding/Safety

- Machine safety (light guards etc.)

- Robot gripper system (bespoke EOAT)

- 6-axis robot(s) depending on payload and reach

- Clip Feeding Equipment – Bowl, Linear & escapement

- Integrated control system with HMI

- Pneumatics – Air prep set/dump valve/valves

- Quick change facility on the machine for the component fixturing (option)

- Vision Inspection System (option)

Contact

Send your message to a member of our team

Read our Privacy Policy to learn how we manage and protect your submitted information.