The product is a blood gas analyser that generates blood gas, metabolite, CO-oximetry and neonatal bilirubin results which are used to diagnose and monitor critical ill patients in an intensive care unit, operating room or emergency room. It is an essential instrument supporting COVID-19 response efforts, where blood gas testing plays a critical role in managing infected patients and monitoring their respiratory distress.

The system works by pumping a blood sample through the measurement cartridge which has multiple sensor types to monitor electrical feedback that relates to the relevant testing metrics. These cartridges last for 28 days or a specific number of samples.

Once a sample has been analysed, the sample path requires cleaning ready for the next sample. The Wash/Waste cartridge is installed, which has a cleaning fluid and bag to capture the waste. This is then disposed of after 9 days or a certain number of samples.

Learn More: RNA Automated Feeding System for COVID-19 testing and vaccination

Solution

The application is a true human-automation collaboration which allows the machine and operator to work at the same time within a limited workspace. The efficient integration of robots and vision into the production line adds significant value due to their reliability and repeatability, resulting in increased product throughput and productivity.

Cartridge Base Infeed

The operator loads cartridge bases through a poke yoke aperture onto a two-lane declined conveyor. The cartridge bases are driven down the track to a stop, where they are picked and placed via a vertical pneumatic actuator and horizonal servo actuator into a nest on the main working conveyor.

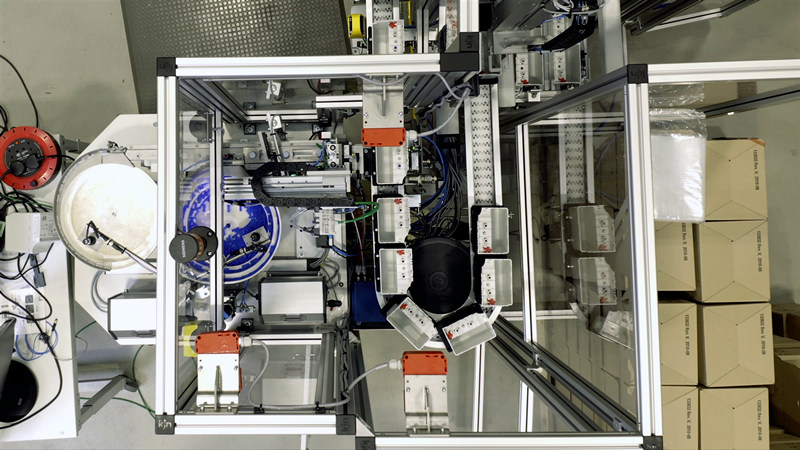

Main Working Conveyor

A re-circulating loop pallet conveyor system which is designed to transport QTY pallets to achieve cycle time, with a nest for the cartridge base to be accurately located within. The pallets are transported around the conveyor, through a combination of location and stop stations positioned at the various work areas for the part assembly process.

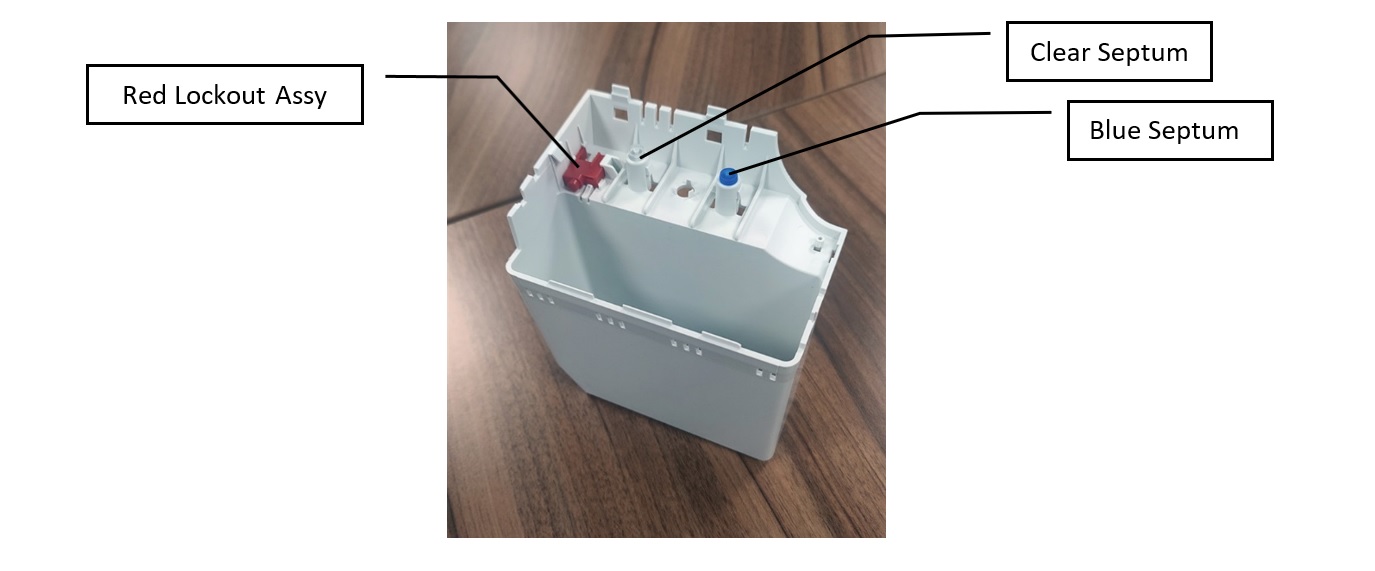

Septum Infeed

Septums are fed and orientated by two vibratory bowl feeders and are then picked and placed into the housing. A vision check confirms that the septums are in the correct port (by colour), that they are completely seated within the cartridge and that the red tab is present. A sensor would check that the red tab isn’t fired.

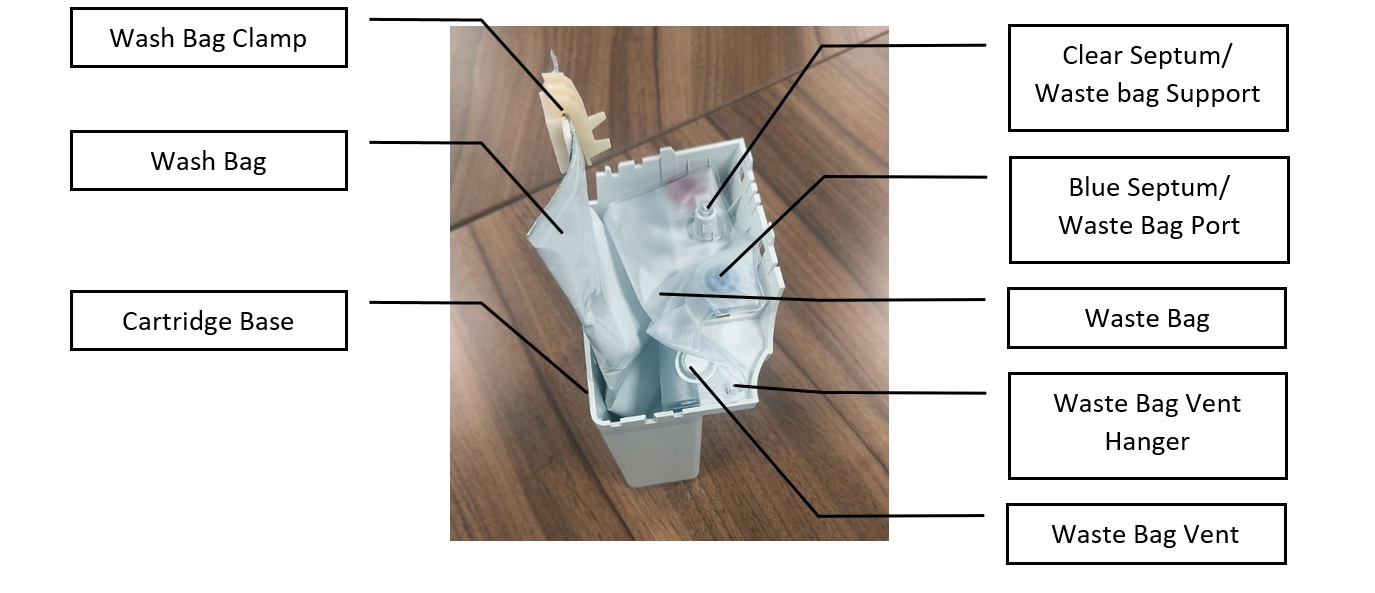

Waste Bag Load

An operator manually loads and fits a waste bag before pressing a two-finger start, which enables a press to extend and push the clip into the cartridge housing. The press measures the force used with reference to the distance travelled by the press to ensure the waste bag has been loaded and fitted correctly. Once completed, either of the finger switches is made and the pallet moves on to the next station.

Wash Bag Load

An operator manually loads and fits a wash bag and supports before actuating a whisker switch for the pallet to be released to the next station.

Bag Vision Check

A vision system checks that the top half of the wash and waste bags are within the perimeter of cartridge base.

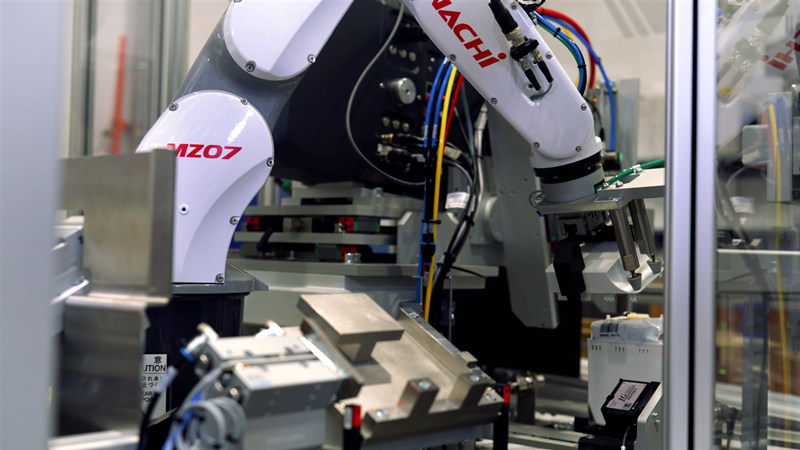

Lid Load

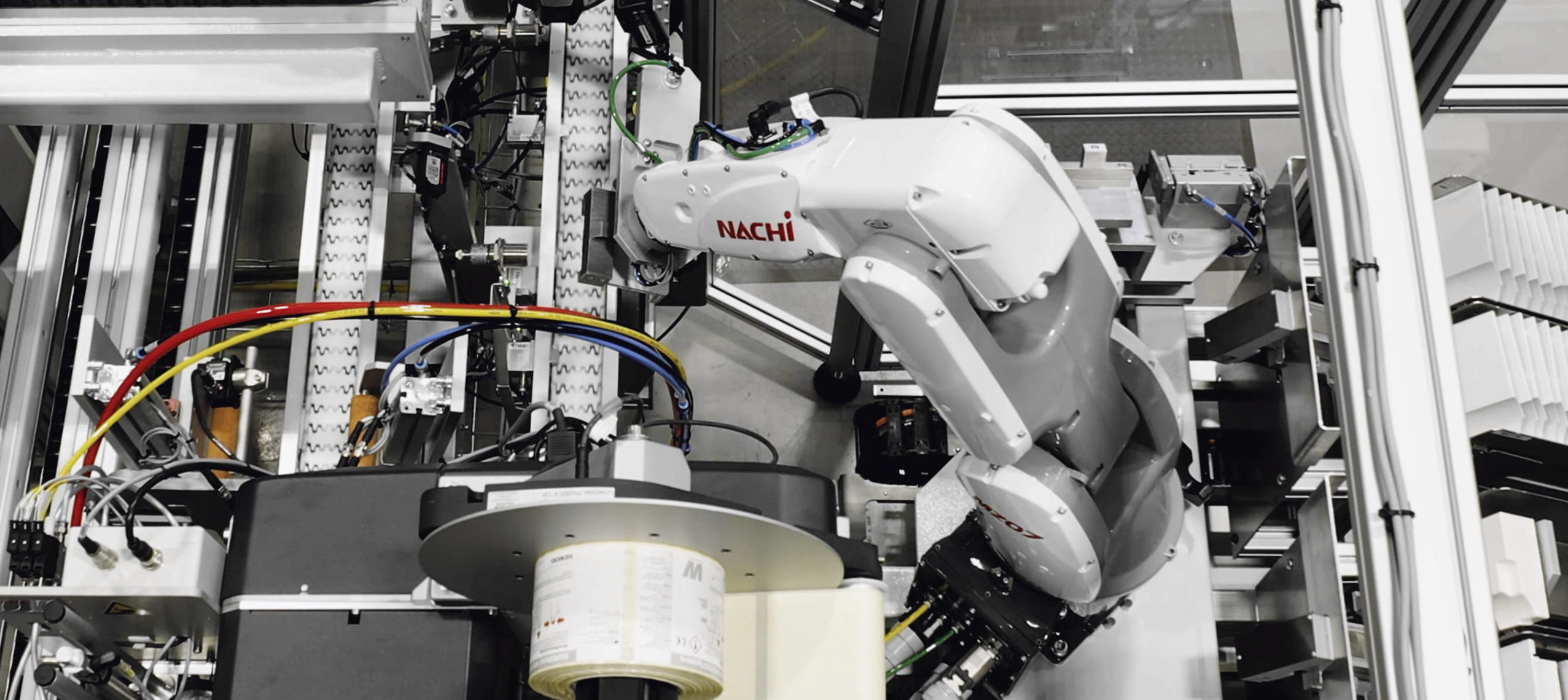

Lids are loaded by an operator into one of two magazine drawers. The magazines can be topped up independently. The magazine, once returned within the cell, is picked from the top of the stack by a six-axis robot and placed into a datum station. Once the lid is accurately located it is picked again by the robot and assembled to the cartridge base. Once fitted, a presence check for lid ‘tabs’ is made.

Label Application & Verification

Assembled cartridges arrive underneath the label applicator where a label is printed and applied to the cartridge. The sides of the label are wiped down, and then a vision sensor performs an OCR check and a barcode scanner check the barcode.

Outfeed Conveyor

Once assembled, cartridges are picked from the pallet on the working conveyor and placed onto an outfeed gravity track, where they travel to an offload area for the operator.

At any station where a failure is detected, the part indexes around to the offload pick and place where it is offloaded into the failure lane. This lane is accessed at the back of the pack station so that it’s completely isolated from the operator who is accessing good cartridges. Failed cartridges can be removed from the cell without interrupting production.

Packaging Station

An operator offloads cartridges and loads into either a single or ‘quad’ box. The box is then loaded into the printing drawer and a two-hand start is activated for the drawer to retract into the station. Inside the station the box is automatically located to a datum position, a label is applied, and the label position and barcode are checked. The operator then activates the two-hand start again and the drawer automatically opens for the operator to remove the box.

Key features & benefits

- Human-automation collaboration of the Wash/Waste Cartridge assembly process

- Efficient integration of robots and vision into the production line

- Increased product throughput and productivity

- Increased repeatability and accuracy

Other Case Studies

Contact

Send your message to a member of our team

Read our Privacy Policy to learn how we manage and protect your submitted information.