Solution

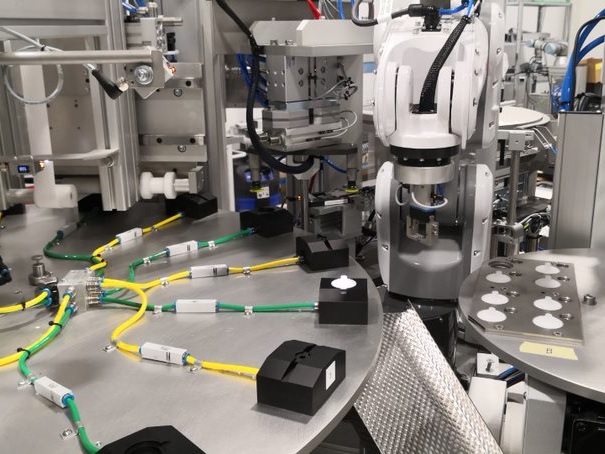

The spray booth is designed based on a six-axis robot with an automatic air spray gun. The automation combines picking and placing tasks with outfeed conveyor systems for the panoramic steel frame to be air-dried.

The spray booth enclosure includes insulated panels, high frequency LED PCB lighting, integrating the robot within the floor for full downdraught air movement.

To start the process, the panoramic frames are manually loaded to the cell nesting. After the cycle start button is pressed, the fast-acting door closes to enclose the spray area to start the spray cycle. The robot picks the panoramic frames and manipulates within the spray path.

On completion the inner fast acting door opens, and the panoramic frames are deposited on the outfeed conveyors to be air-dried. Once deposited the inner door closes and the robot is in the park position ready for the front door to open.

A human-machine interface (HMI) is integrated, giving instructions to the operator and enabling easy configuration of parameters and monitoring of the whole operation.