The automated assembly line revolutionized the manufacturing industry by introducing a groundbreaking method for mass production. The concept of an assembly line involves dividing the production process into a sequence of interconnected stations, where each station is responsible for specific tasks. Among the different types of automated assembly lines, the rotary assembly line stands out as a prime example of seamless integration and optimization.

In this article, we will explore the different types of automated assembly lines, with a particular focus on the rotary assembly line and its benefits.

Types of Automated Assembly Lines

Fixed Sequence Automated Assembly Line:

The fixed sequence automated assembly line is the most common type of automated assembly line. In this system, the product moves along a fixed path, following a predetermined sequence of tasks. Each station along the line is equipped with automated machinery and robots, responsible for carrying out specific operations. While efficient and reliable, this type of assembly line may have limitations in adapting to changes in product design or production requirements.

Flexible Automated Assembly Line:

The flexible automated assembly line addresses the limitations of fixed sequence lines by incorporating a higher degree of adaptability. These lines utilize advanced robotic systems capable of adjusting their operations based on the product’s characteristics or specific production demands. This adaptability enhances production versatility, enabling manufacturers to switch between different product types without significant downtime.

Intelligent Automated Assembly Line:

The intelligent automated assembly line leverages cutting-edge technologies, such as artificial intelligence and machine learning, to optimize production processes. These systems can make real-time decisions, self-adjust, and predict potential faults or inefficiencies. By analysing data from various sensors and feedback loops, the intelligent assembly line continuously improves its performance, resulting in higher productivity and reduced waste.

Automated Rotary Assembly Line: A Marvel of Efficiency

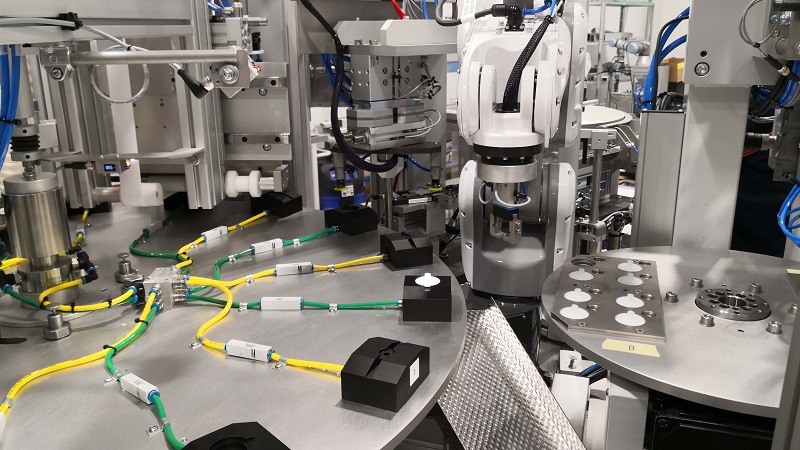

The rotary assembly line is a form of the circular assembly line, which as the name suggests, adopts a circular layout. In an automated rotary assembly line, the product is placed on a rotating platform or turntable (known as rotary indexing table) that moves in a circular motion. Surrounding the platform are a series of workstations equipped with robotic arms, conveyors, and other automated equipment.

Read more:

- Automation is the Catalyst for Factory Transition

- How do Industrial Automation Expectations Differ from Reality

- Semi-Automated vs Fully Automated: Which one is right for your manufacturing process?

Application studies:

Medical Filter Assembly Machine for Overmoulding

Medical Filter Assembly Machine for Overmoulding

Switch Body Pad Printing Machine with Rotary Indexing Table

Switch Body Pad Printing Machine with Rotary Indexing Table

Advantages of Automated Rotary Assembly Line:

- Continuous Production: Automated Rotary assembly lines offer continuous production flow, reducing downtime and maximizing productivity. The product’s rotation ensures a smooth transition from one station to another, minimizing the waiting time between tasks.

- Enhanced Efficiency: With the product rotating to each workstation, there is minimal need for material handling or repositioning. This streamlines the assembly process, reduces bottlenecks, and enhances overall production efficiency.

- Space Optimization: Rotary assembly lines are known for their compact layout, making them suitable for manufacturing facilities with limited space. The circular design maximizes floor area usage, allowing manufacturers to make the most of their available resources.

- Precision and Quality: Automated systems in the rotary assembly line ensure consistent and precise assembly of products. The robotic arms and machinery execute tasks with high accuracy, minimizing the risk of errors and defects, thereby improving product quality.

- Adaptability: Rotary automated assembly lines can be configured to accommodate various product types or undergo rapid changeovers. This flexibility is especially valuable in industries with frequent product updates or customization requirements.

Automated assembly lines have transformed the manufacturing landscape, and various types of automated assembly lines have been developed to cater to different production needs. Among these automated systems, the rotary assembly line shines as a pinnacle of efficiency, combining continuous production, space optimization, and precision. As technology continues to evolve, the future holds exciting possibilities for further advancements in automation, enabling manufacturers to stay at the forefront of innovation and deliver superior products to consumers worldwide.