Diving into the world of manufacturing, it’s clear that bowl feeders play a transformative role in the consumer goods sector. But what exactly are they?

What Are the Basics of Bowl Feeders?

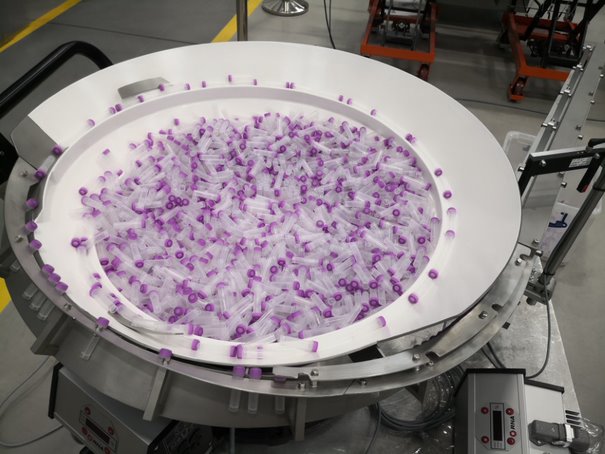

At their core, bowl feeders are vibratory systems utilised to orientate and sort parts. With a vibrating drive unit and a variable-amplitude controller, the bowl resonates, causing parts inside to shift, positioning them uniformly, ready for assembly or packaging.

However, at RNA we offer varying bowl feeders that accommodate the needs of handling unique parts, elements and products with ease and care. By finding a bespoke automated solution for your production line, you’ll be able to increase output and maintain fulfilment expectations with the support of RNA behind you.

Why Are Bowl Feeders So Versatile in Consumer Goods Manufacturing?

RNA Automation, one of the leaders in the field, has highlighted the extensive versatility of bowl feeders. Spanning various sectors, from electronics to beauty products, bowl feeders ensure that manufacturing operations remain smooth, precise, and effective.

How Do Bowl Feeders Aid in Electronics Assembly?

Within the electronics realm, bowl feeders, as championed by companies like RNA Automation, are indispensable. They streamline the sorting and alignment of electronic parts into consistent orientations. Such systematic arrangement accelerates assembly, whether it’s fixing components on printed circuit boards or piecing together mobile phone components.

What Role Do Bowl Feeders Play in Battery Manufacturing?

In the realm of battery manufacturing, where precision and accuracy are critical, bowl feeders are essential. They guarantee that components, such as battery cells or connectors, are aptly oriented for assembly. This efficiency not only expedites the manufacturing process but also reinforces the quality and reliability of the batteries.

How Do Bowl Feeders Contribute to Cosmetics and Personal Care Products?

In the cosmetics and personal care industry, the presentation is of utmost importance. Bowl feeders assist in positioning items – be it lipstick tubes, mascara wands, or other vessels – with utmost accuracy. This meticulous arrangement ensures that processes like labelling, branding, and sealing are executed seamlessly.

Why Are Bowl Feeders Essential in Medical Device Manufacturing?

For an industry where safety and exactness are paramount, bowl feeders are invaluable. Whether organising syringe elements or assembling intricate medical tools, bowl feeders guarantee parts are rightly aligned, ensuring impeccable assembly and packaging.

What Benefits Do Bowl Feeders Offer in Consumer Goods Manufacturing?

- Efficiency: They facilitate rapid sorting and orientation, enhancing production speed.

- Precision: Bowl feeders consistently ensure accurate orientation, minimising mistakes.

- Versatility: With companies like RNA Automation, bowl feeders can be tailored to manage a vast array of components, irrespective of their form, dimensions, or material.

- Economical: Automating orientation processes reduces labour costs and minimises waste attributed to human inaccuracies.

RNA speaks on bowl feeders –

Chris from RNA commented,

What Future Advancements Can We Anticipate for Bowl Feeders?

The manufacturing landscape is in constant flux, with bowl feeders being no exception.

How Will Integration with Smart Manufacturing Impact Bowl Feeders?

RNA Digital Solutions have developed simulation tools to create digital feeding systems enabling design validation and faster implementation times, enabling customers to enjoy the benefits quicker.

What Role Will Collaborative Robotics Play?

Rather than operating in isolation, humans and robots are beginning to collaborate more frequently, courtesy of advances in robotics. Bowl feeders will integrate seamlessly with these robotic systems, endorsing a more streamlined and effective production line.

How Will Enhanced Connectivity and Communication Influence Bowl Feeders?

With the burgeoning Internet of Things (IoT) in manufacturing, bowl feeders won’t function in isolation. They’ll be part of an interconnected framework, allowing for continuous data transfer, facilitating superior monitoring, troubleshooting, and optimisation.