Collaborative Robot Integration

RNA Automation | Integrator of Universal Robots

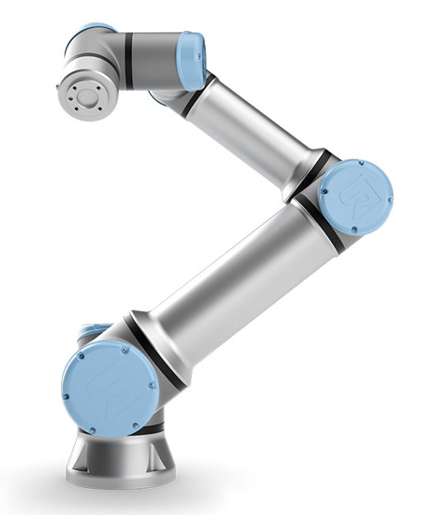

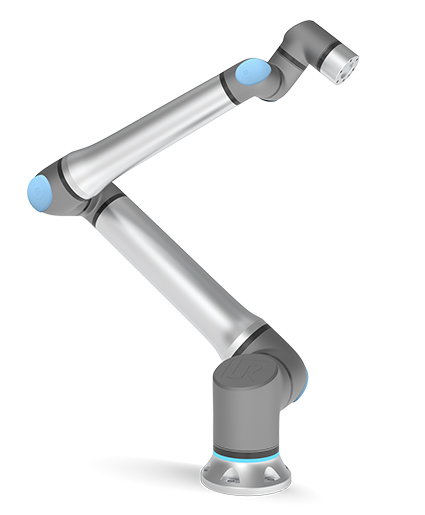

As the world leaders in the collaborative robot market, Universal Robots are versatile, safe, easy-to-use and install, and competitively-priced. The Universal Robots have 6-axis articulated arms with highly-sensitive torque sensors that detect any change in force or pressure that causes it to stop. They are easily programmable and suitable for a wide range of applications.

UR3e | UR5e | UR10e | UR16e | UR20 | |

Reach | 500 mm / 19.7 ins | 850 mm / 33.5 ins | 1300 mm / 51.2 ins | 900 mm / 35.4 ins | 1750 mm / 68.9 ins |

Payload | 3 kg / 6.6lbs | 5 kg / 11 lbs | 12.5 kg / 27.55 lbs | 16 kg / 35.3 lbs | 20 kg / 44.1 lbs |

Footprint | Ø 128 mm | Ø 149 mm | Ø 190 mm | Ø 190 mm | Ø 245 mm |

Weight | 11.2 kg / 24.7 lbs | 20.6 kg / 45.4 lbs | 33.5 kg / 73.9 lbs | 33.1 kg / 73 lbs | 64 kg / 141.1 lbs |

EASY PROGRAMMING | FAST SET-UP | FLEXIBLE DEPLOYMENT | COLLABORATIVE AND SAFE |

Patented technology lets operators with no programming experience quickly set up and operate our cobots with intuitive, 3D visualization. Simply move the robot arm to desired waypoints or touch the arrow keys on the easy-to-use touchscreen tablet. | Universal Robots has revolutionized cobot set-up, reducing typical robotic deployment measured in weeks to a matter of hours. The average set-up time reported by our customers is only half a day. The out-of-box experience for an untrained operator to unpack the cobot, mount it, and program the first simple task is typically less than an hour. | Don’t be limited by dedicated robotics. Universal Robots are lightweight, space-saving, and easy to re-deploy to multiple applications without changing your production layout. Moving the cobot to new processes is fast and easy, giving you the agility to automate almost any manual task, including those with small batches or fast change-overs. The cobot is able to re-use programs for recurrent tasks. | Now you can replace human operators in dirty, dangerous, and dull jobs to reduce repetitive strain and accidental injuries. Eighty percent of the thousands of UR robots worldwide operate with no safety guarding (after risk assessment), right beside human operators. The safety system of our robots is approved and certified by TÜV (The German Technical Inspection Association). |

The Universal Robots collaborative robots (cobots) are simple, smart and safe robots that work alongside operators without safety fencing and guarding. As a robotic system specialist with nearly 30 years experience, RNA understand collaboratvie robot capabilities and technologies. We will analyse your application and provide best collaborative robots solution to meet the application’s needs and restrictions.

What are Cobots?

If recent research is anything to go by, collaborative robots (cobots) are the workforce of the future.

Robots have been widely used in the manufacturing industry for many years to replace human labour, however collaborative robots or ‘cobots’ are an entirely different ball game. The definition of collaboration is the action of working with someone to produce something and cobots are designed with that in mind, working alongside other employees and not as a replacement to them.

Some operations and activities simply cannot be fully automated, however the process speed suffers if parts are being ferried backwards and forwards between workers on the assembly line from robots locked in cages. Cobots could transform the way we work and manufacturers like Ford have already jumped on the cobot bandwagon.

How RNA Help

Cobot Integration, System Design and Supply

RNA design and develop cobot solutions to optimise your production process. We build systems that integrate a collaborative robot with other elements such as vision system, conveyors.

Hands-on demonstration

As it is so easy to program and so quick to set up, RNA provide hands-on demonstrations. If you would like to see a cobot in action, it can be done on site and in the space for just a few hours. Contact us to schedule an onsite demonstration.

Technical and application support services

Collaborative robot arms are used in thousands of applications every day. From automotive and aeronautics to picking, placing and machining. If you need assistance with your cobot application, we can help.

Grippers and robotics End-of-Arm tooling

RNA provide you tooling solutions that allow your cobot to do more.

Tailored Cobot Systems

RNA design and develop collaborative robots (cobots) automation solutions – all tailored to customers’ specific manufacturing needs. Let our collaborative robot integration engineering experts help.

Best Collaborative Robot Tasks

Quick and short tasks

- Repetitive tasks or tasks that require high dexterity

- Unstructured tasks

- Manufacturing

- Fine assembling

SMEs could benefit greatly from the use of cobots due to their more dynamic and less-structured environment.

Industry Applications

Assembly

Machine Tending

Welding

Polishing & Deburring

Gluing & Bonding

Press Forming

Plastic Injection Support

Service

Contact

Send your message to a member of our team

Read our Privacy Policy to learn how we manage and protect your submitted information.