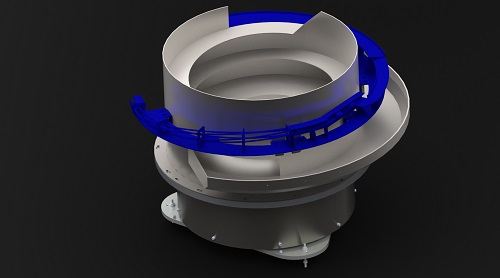

Vibratory Bowl feeders are a traditional way of handling and sorting bulk products to further processing machinery and packaging lines. The vibratory bowl feeder has not changed greatly over the years and remain a robust and reliable solution in place of a line operator.

Bowl feeders come in many shapes and sizes and can be used in the pharmaceutical, food, automotive, electronics and packaging industries to name a few. The most common and widely used area for a bowl feeder is to present parts one by one orientated all one way to an assembly machine or processing line. The parts are then either assembled packaged or counted into batches.

A bowl feeder can process parts up to 10 meters per minute giving an accurate and continuous supply to the machine or processing line. For Pharmaceutical and food grade applications bowl feeders are manufactured from a high grade of stainless steel (316L) and fully welded to meet stringent clean room conditions.

A typical bowl feeder would be integrated into a complete system which would include a bulk hopper or bulk handling storage device, an outfeed track (linear vibrator) and control system. The bowl feeder should be designed to run at the required rate + 10% and turn on and off automatically via sensors integrated into the control box.

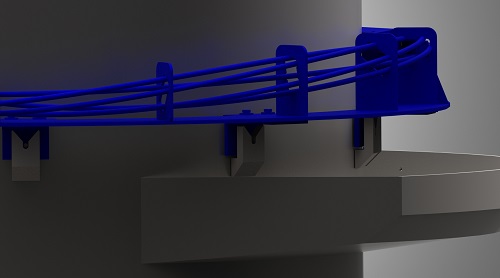

When applying a bowl feeder the component parts to be orientated are the main area of consideration, part shape, parts size, weight and material properties must be taken into account. Special linings and coatings of the bowl feeder surface must be used to help with traction of the component when orientating and feeding. Coatings can cater for oily and sticky parts and can also be used for food grade applications (FDA Approved).

An inline track is used after the bowl feeder as a means of accumulation, usually this would hold at least 20 seconds worth of orientated parts and feed directly into the machine or processing line. A bulk hopper would hold a defined number of parts and dose the bowl feeder on demand from its control system. This gives the operator a window of time between fill ups and acts as a bulk storage device. Bowl feeders are often enclosed within an acoustic cover to keep noise levels low and meet with current Factory regulations.

How to choose? There are most likely more than one viable solutions for your product. Talk to one of our experts to guide you through the options to help select the best option for your application.