The life science industry plays a crucial role in advancing healthcare, pharmaceuticals, and biotechnology. To meet the ever-increasing demands for precision, efficiency, and reliability, life science manufacturers are turning to advanced automation solutions. Among these, the rotary indexing system has emerged as a powerful tool, streamlining various production processes in the life science sector.

In this article, we will explore the applications of the rotary indexing system in the life science industry and its significant contributions to advancing medical technology.

Understanding the Rotary Indexing System in the Life Science Industry

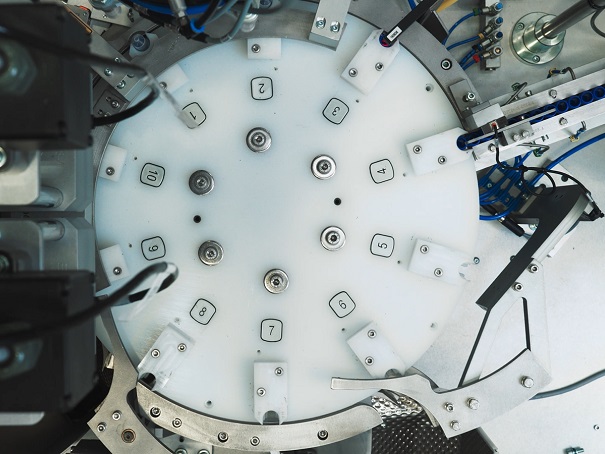

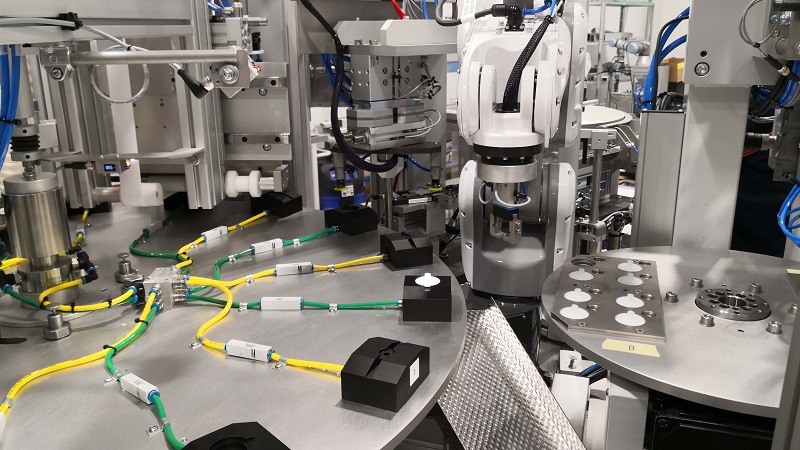

The rotary indexing system is an automation technology designed to accurately position and move workpieces through a series of fixed angular increments or stations. It enables seamless rotation of workpieces, allowing for precise assembly, filling, and packaging operations. This system optimizes workflow, reduces manual handling, and ensures consistent and high-quality production, making it an ideal fit for the life science industry.

Applications of Rotary Indexing System in the Life Science Industry

Pharmaceutical Packaging:

In the pharmaceutical industry, the rotary indexing system is employed in the packaging of various medicinal products. The system’s ability to efficiently rotate containers through filling, capping, and labelling stations ensures uniform and error-free packaging. It enables the pharmaceutical industry to meet strict regulatory requirements and enhance product safety.

Medical Device Assembly:

The assembly of medical devices often involves intricate components and strict quality control measures. Rotary indexing systems facilitate the precise assembly of medical devices, such as infusion pumps, surgical instruments, and diagnostic equipment. The system’s accuracy and consistency contribute to reliable and safe medical devices.

Diagnostic Test Kit Manufacturing:

Diagnostic test kits are vital tools for detecting and monitoring diseases. The rotary indexing system plays a pivotal role in assembling and packaging diagnostic test kits, ensuring the correct arrangement of reagents and components. This precision is critical for accurate test results and timely medical interventions.

Biotechnology and Genetic Analysis:

In the biotechnology field, the rotary indexing system is used for high-throughput genetic analysis, such as DNA sequencing and PCR (Polymerase Chain Reaction). The system allows for automated sample handling and processing, increasing the throughput of genetic analysis workflows and reducing human error.

Vaccine Production:

Vaccine production demands precise handling of biological materials to maintain efficacy and safety. Rotary indexing systems aid in the automation of vaccine manufacturing processes, such as filling vials with the appropriate vaccine dose and sealing them securely.

Advantages of Rotary Indexing System in the Life Science Industry

- Improved Efficiency: The rotary indexing system streamlines production processes, minimizing downtime and manual intervention, leading to increased productivity and throughput.

- Enhanced Accuracy: The system’s precision ensures consistent positioning of workpieces, reducing errors in assembly and packaging processes and improving overall product quality.

- Compliance with Regulatory Standards: In the highly regulated life science industry, the rotary indexing system helps manufacturers adhere to strict quality control and safety guidelines, ensuring compliance with regulatory authorities.

- Scalability: The modular design of the rotary indexing system allows for easy integration and scalability, making it adaptable to changing production needs and product variations.

Conclusion

The life science industry demands uncompromising precision and efficiency to drive innovation and improve patient outcomes. The rotary indexing system has emerged as a vital automation technology, contributing significantly to the advancement of life science manufacturing processes. From pharmaceutical packaging to medical device assembly and genetic analysis, the system’s applications are diverse and impactful. By harnessing the capabilities of the rotary indexing system, life science manufacturers can continue to push the boundaries of medical technology, bringing novel treatments, diagnostics, and therapies to millions of people worldwide.