The UK, along with many other countries, is facing a labour shortage across all sectors including manufacturing and operations. Covid, an ageing workforce, changing employee expectations have all contributed to high numbers of unfilled positions.

So how best to meet the challenge of diminishing human resources? The clue is in our name. RNA Automation offers smart manufacturing solutions that can help businesses optimise operations, and not necessarily at the expense of the workforce.

Optimise your output with automation

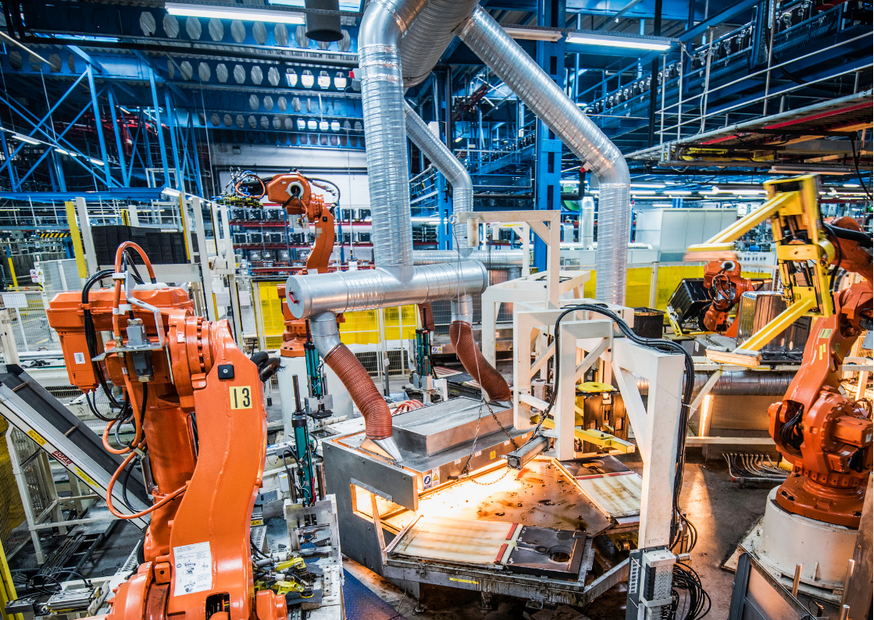

Initially – and rather unfairly – seen as a job killer, automation can actually be a key to significantly increased output, optimising both production and the allocation of skills within the business. Our vision systems and robotics are renowned for requiring minimum human intervention, but it’s not necessarily about saving labour costs – more that staff can be deployed on more complex and productive tasks.

There is a solution – automation must be considered for keeping production lines moving. At RNA Automation we can deliver the optimal flexible system for multiple products, whether it’s upgrading paint spraying motor vehicles in a state-of-the-art automotive factory or feeding the nation’s craving for chocolate and assorted confectionery with high-resolution vision systems.

Automation versus the human touch

Many manufacturers blame declining sales volumes on struggling to find the right qualified people to fill the vacancies, and fulfil the potential orders they have on their books.

Manufacturing is not viewed as one of the more desirable working environments so well qualified engineers will usually command premium wages to attract them in the first place – and then stop them defecting to a competitor offering more money or better benefits.

RNA Sales Director, Dave Hanslow, says: “Instead of hunting for staff to fill vacancies, robotics and/or automation should be considered as viable alternatives. Using our decades of machinery design experience, we can tailor equipment to meet the customer’s requirement.

Our trained and highly experienced engineers can always spot a cost-effective automated process where one person is needed rather than six.”

Save costs – don’t create them

Automation offers a sensible permanent solution to the labour shortfall. Investing in robotics and smart processes reduces recruitment costs and can boost productivity by making workflows more efficient.

At RNA we’re very flexible and have a great understanding of what companies can afford. We’re very flexible – we can tailor our automation concept to a cost that fits with any business.

At RNA we’re very flexible and have a great understanding of what companies can afford. We’re very flexible – we can tailor our automation concept to a cost that fits with any business.

Before committing to delivery of an end solution we carry out a proof of principle to develop and validate a working concept of the solution. This de-risks the project for both the machine builder and the customer and ensures they get exactly what they need to the very highest standards.

Dave explains: “We are seeing a surge of enquiries particularly from businesses for which we quoted automation a few years ago. Subsequent events have caused a change of tack from sticking with operators to the realisation that investing in automation is more cost-effective for the business. Remember, automation will also release staff from mundane, repetitive tasks to perform other, more highly skilled tasks.”

There are also potential physical consequences for employees repetitively handling items on a production line. It is estimated that Repetitive Strain Injury (RSI) costs UK industry between £5 billion and £10 billion every year.

Automating mundane processes eliminates the risks associated with RSI as well as the administrative hassle of dealing with compensation claims.

Effective integration of automated solutions

Are we talking about human-free factories in the future? We don’t think so. Factories and processes have changed massively over the years.

Millions of pounds have been invested in replacing people with machines but there will always be a need for a human to be part of a manufacturing process. Vision, robotics and guided systems can do most of the legwork but you’ll always need an operator’s hand-eye co-ordination somewhere down the line – not to mention someone to tell the machinery what to do!

Automation can replace missing workers but the technology can also upskill a workforce. Automation can be another key to significantly increased output, optimising both production and the allocation of skills within the business.

So, to sum up. Our levels of enquiries reflect that more and more companies see the need to automate, but it doesn’t necessarily mean throwing out the baby with the bathwater! Whether it’s a major luxury car manufacturer, or Jim’s Buckets, you can trust RNA to examine a process in fine detail and determine if it’s viable for a customer to replace human labour with a cost-effective automated system.

* Office of National Statistics (ONS). www.ons.gov.uk

END

Background

RNA Automation Ltd is a leading supplier of specialised automation engineering solutions. The company provides bespoke systems for advanced manufacturing industries including cosmetics, pharmaceutical, medical devices, electronics, plastics, metal working, food, consumer goods and automotive.

From its modern factory situated in the West Midlands RNA is capable of solving automation requirements in combination with its mission of quality, reliable service and back up. RNA has been established in the UK since 1986 and is renowned for an extensive product range and innovation.

With around 2000 systems supplied annually, RNA has a wealth of experience to draw upon. It can supply bespoke automated systems, feeding and handling, rotary indexing machines, inspection and vision systems and robotics.