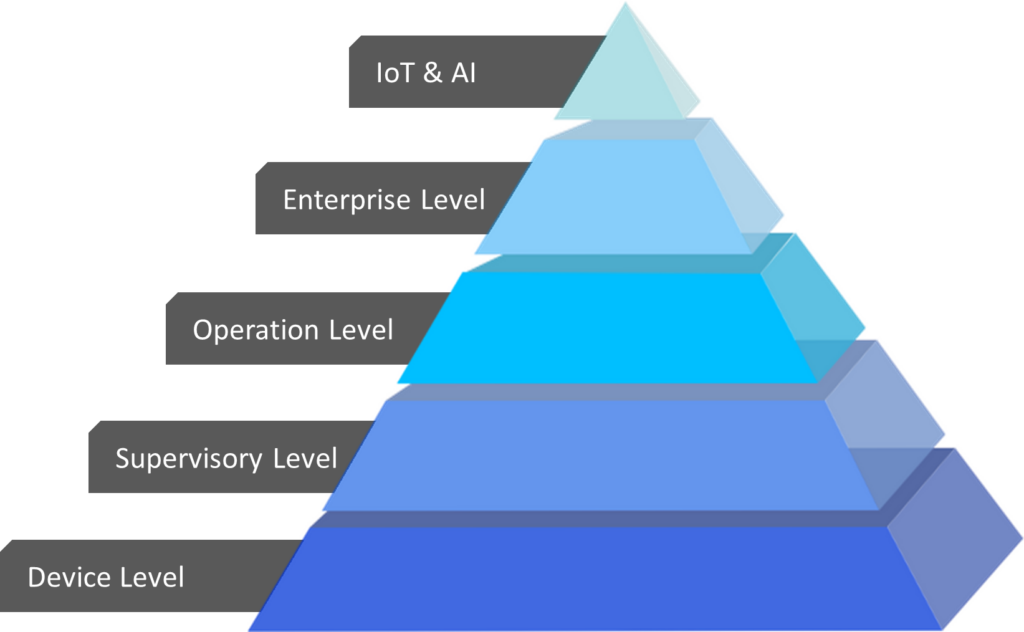

As the manufacturing industry progresses towards increased efficiency and productivity, automation has become the driving force behind this transformation. To understand the different stages of automation in a factory setting, we explore the concept of the Five-Level Automation Pyramid. This pyramid represents the progression of automation in factories, from basic control systems to highly interconnected and intelligent production environments. Let’s delve into each level of the automation pyramid and explore how it is revolutionizing the modern factory.

Level 1: Device Level

This level represents the foundation of automation, where individual devices and machines are connected to the factory network. It involves the integration of sensors, actuators, and other devices to enable basic automation functions. This level focuses on individual machine control, such as on/off switches, speed control, and basic monitoring. It forms the foundation for higher levels of automation by providing the essential infrastructure for data collection and communication.

Level 2: Supervisory Level

Moving up the pyramid, we reach the Supervisory Level. Here, the focus shifts towards centralized supervision and control of multiple devices and processes. Supervisory control systems, such as Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems, play a crucial role in monitoring and managing production operations. This level enables real-time monitoring, data visualization, and basic decision-making capabilities, allowing operators to gain insights into the overall production process, track key performance indicators, and make informed adjustments to optimize operations.

Level 3: Operation Level

As we ascend further, we reach the Manufacturing Operations Level. This level focuses on bridging the gap between the shop floor and the enterprise level. It involves the integration of Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) systems, enabling seamless communication and data exchange between the production floor and the business operations. The Manufacturing Operations Level facilitates real-time production monitoring, quality management, inventory control, and resource optimization.

Level 4: Enterprise Level

The Enterprise Level brings in the enterprise resource planning (ERP) system, which integrates business functions such as finance, supply chain management, human resources, and customer relationship management. It enables data synchronization across the entire organization, ensuring seamless communication between the factory floor and higher-level decision-making processes. ERP systems provide real-time visibility into production and enable data-driven strategic planning.

Level 5: Internet of Things (IoT) and Artificial Intelligence (AI)

The pinnacle of the automation pyramid is level 5, where automation reaches its highest form. It involves the utilisation of advanced technologies such as the Internet of Things (IoT), Artificial Intelligence (AI), Machine Learning (ML), and Big Data analytics. At this level, machines, devices, and systems are interconnected, creating an intelligent and self-optimizing factory ecosystem. IoT sensors collect vast amounts of data, which is processed by AI algorithms to drive predictive analytics, machine learning, and autonomous decision-making. This level enables predictive maintenance, advanced quality control, adaptive production, and the creation of agile and flexible manufacturing systems.

The Five-Level Automation Pyramid provides a comprehensive roadmap for the evolution of factories into intelligent and interconnected production environments. From the foundational Device Level to the integration of IoT and AI, each level builds upon the previous one, enabling enhanced efficiency, productivity, and agility. Embracing the automation pyramid requires careful planning and investment in technology. As factories of the future continue to evolve, the automation pyramid serves as a compass, guiding manufacturers toward achieving the full potential of Industry 4.0 and redefining the way we produce goods in the modern world.