Manufacturing processes have evolved greatly over the past few decades, and one of the most significant changes has been the introduction of automation. Automated systems in manufacturing have revolutionized the way products are made, and they have made the process faster, more efficient, and more accurate.

There are two main types of automated systems used in manufacturing: semi-automated and fully automated systems. In this article, we will explore the difference between semi-automated and fully automated systems in the manufacturing process.

Semi-Automated System

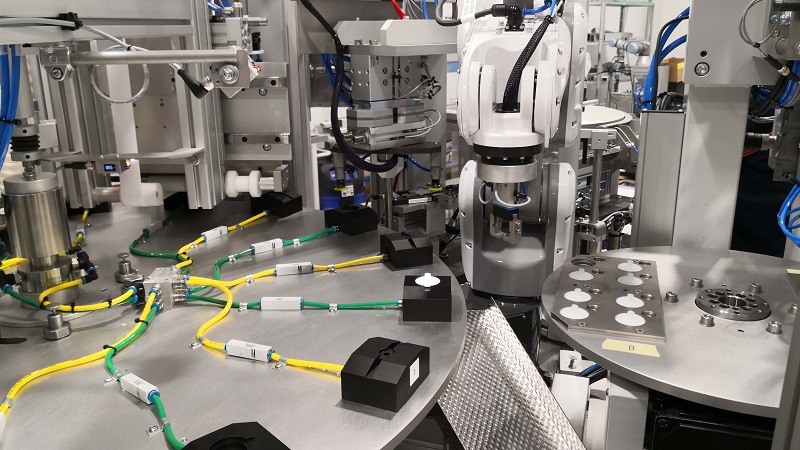

One of the primary advantages of semi-automated systems is that they allow for greater flexibility in the manufacturing process. Because human workers are still involved, they can adapt to changing conditions or unexpected events more easily than a fully automated system. This can be especially important in industries where there is a lot of variability in the products being manufactured.

Semi-automated systems can be highly effective in reducing labour costs while still maintaining a high level of quality control. They are also generally less expensive to implement than fully automated systems, making them a popular choice for smaller manufacturers or those with limited budgets.

However, semi-automated systems also have some drawbacks. Because they rely on human operators for some tasks, they are more susceptible to human error, which can lead to increased waste and lower quality output. They also require more space and can be less efficient than fully automated systems.

Fully Automated System

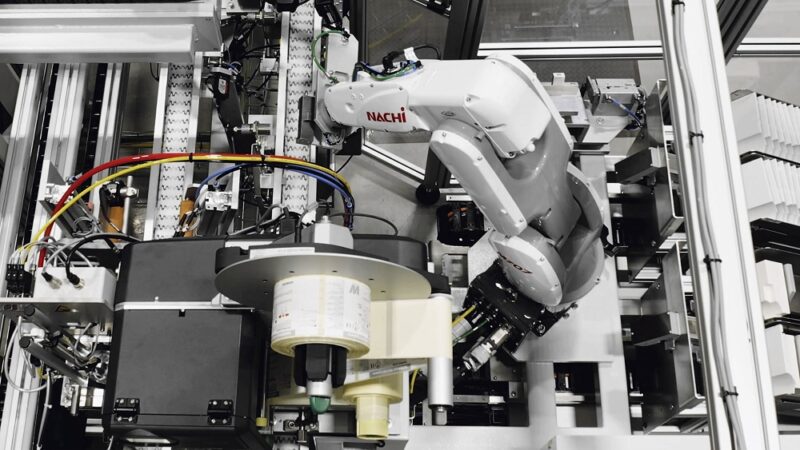

The primary advantage of fully automated systems is speed and efficiency, as they eliminate the need for human operators and can operate 24/7 without interruption. They can perform tasks more quickly and with greater precision than a semi-automated system. This makes them ideal for industries where high volume and speed are important.

Fully automated systems also have the advantage of consistency. Because they do not rely on human labour, there is less variability in the products being manufactured, which can be important in industries where product quality is critical.

However, fully automated systems will be more expensive to implement. Additionally, because they rely solely on machines, they can be less flexible than semi-automated systems and may not be able to adapt to changing production needs.

Which one is right for your manufacturing process?

Both semi-automated and fully automated systems have their advantages and disadvantages. While semi-automated systems are generally less expensive to implement and more flexible, they are also more susceptible to human error and may be less efficient than fully automated systems. On the other hand, fully automated systems are highly efficient and produce goods with a high level of consistency and quality, but they can be expensive to implement and less flexible.

Ultimately, the choice between a semi-automated or fully automated system will depend on a number of factors, including the size and budget of the manufacturer, the complexity of the manufacturing process, and the desired level of productivity and quality. By carefully considering these factors, manufacturers can choose the system that best meets their needs and helps them achieve their production goals.

RNA Automation can work with you to help decide which type of automation is the most valuable to you. Get in touch to find out how we can help.

END

Background

RNA Automation Ltd is a leading supplier of specialised automation engineering solutions. The company provides bespoke systems for advanced manufacturing industries including cosmetics, pharmaceutical, medical devices, electronics, plastics, metal working, food, consumer goods and automotive.

From its modern factory situated in the West Midlands RNA is capable of solving automation requirements in combination with its mission of quality, reliable service and back up. RNA has been established in the UK since 1986 and is renowned for an extensive product range and innovation.

With around 2000 systems supplied annually, RNA has a wealth of experience to draw upon. It can supply bespoke automated systems, feeding and handling, rotary indexing machines, inspection and vision systems and robotics.