3D printing and additive manufacturing are a subject on everyone’s lips. And as the largest manufacturer and supplier of vibratory bowl feeding equipment in Europe, RNA have been breaking new ground in this innovative technology for more than five years. Cost savings, rapid production, flexible material selection and, of course, 100% repeatable production are the main advantages of adopting this technology.

The use of 3D printing can evaluate bowl designs, check partial elements of the feed, test surface behaviour and orientation, making necessary adjustments and eliminate any potential production bottlenecks.

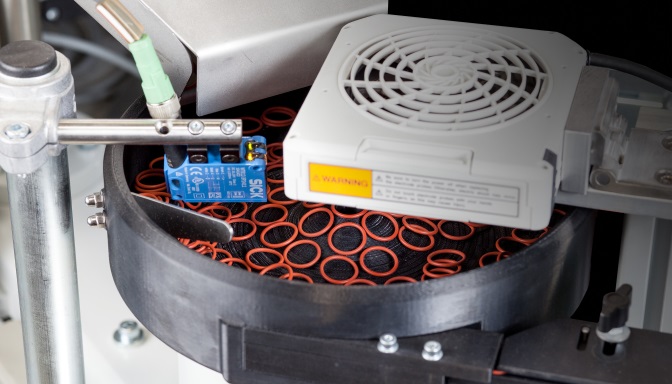

RNA have benefited from reduced development and production time of bowls and tooling through 3D printing. The following picture shows the latest design for our 3D printed vibratory bowl feeders handling O-rings, for use in the packaging industry. The four bowl feeders are printed identically and are then put to the acid test. A nylon material with an anti-static additive is used for the bowl, which increases the feed rate by negating the static that is created from feeding the O-rings. Each bowl feeder achieves a performance of 70 parts per minute. All the development knowledge from conventional feeding and handling technology that RNA has established over the years in O-rings handling systems can also be incorporated into these systems, such as the Teflon coating of certain product-contacting surfaces.

Moreover, the in-house 3D printing enables RNA produce tooling faster and at a lower cost, allowing flexible design and manufacturing processes.

Learn more about our 3D Printed Bowl Feeder, contact us today.

A nylon material with an anti-static additive is used

A nylon material with an anti-static additive is used 3D printed vibratory bowl feeders handle O-rings

3D printed vibratory bowl feeders handle O-rings