Flexible Feeding and Handling: How does VariPic™ work

The VariPic™ is a flexible feeding and handling system, supplied by RNA Automation. Part of RNA’s standard machine offering, the VariPic™ is pre-designed to take component parts from bulk, singulate and present for the next stage of production.

- Bulk Hopper

- RNA VariPic™ Conveyor

- 6-Axis Robot

- Vision Inspection System

- Integrated Control System with HMI

All system elements are configured to the individual needs of the project, providing complete flexibility.

How does it work?

The following system elements are included as standard with the RNA VariPic™:

Bulk Hopper

The hopper is designed to provide a feeding system with a bulk storage of parts. This ensures a constant flow of product over a set period of time, increasing the systems autonomy.

RNA supply a suite of hoppers to suit the customers application. Some examples of hoppers include:

- Belt hoppers (BU-W range): These hoppers utilise a belt to move product from the hopper to the next phase of the process. They are typically used for high-flow applications. Fill volume from 5 – 200 litres.

- Vibratory hoppers (BVL range): These hoppers use vibration to move product from the hopper to the next phase of the process. They are typically used for applications where the material is difficult to flow. Fill weight up to 50kg.

- Elevator hoppers (BU-S range): These hoppers transfer product from a low level to a high level, allowing an operator to load at a more comfortable height. They are often used with bulkier parts. Filling volume up to 350 litres.

A bulk hopper comes as standard with the VariPic™. Your RNA applications engineer will advise the perfect type and size for your application.

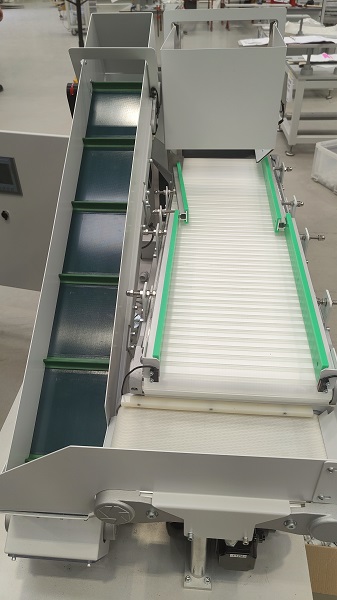

RNA VariPic™ Conveyor

Product is transferred from bulk to an inspection pick window via the RNA VariPic™ conveyor. Different products will require different belt surfaces and sizes to protect them as they flow through the feeding system. Your RNA applications engineer will advise the perfect type, size and material for your application.

Factors that are considered include:

- The weight and size of the product.

- The speed at which the product will be transported.

- The environment in which the product will be transported.

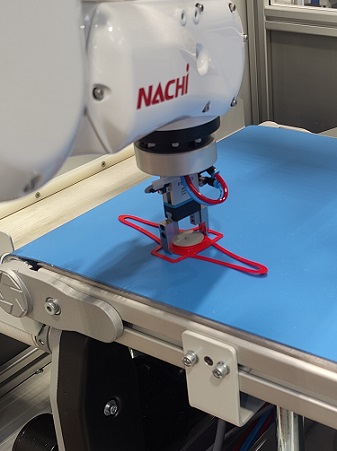

6-Axis Robot

A 6-axis robot comes as standard with the RNA VariPic™. Payload (maximum weight), reach and environment considerations will be pivotal to selecting the right robot for the application.

The robot will be equipped with suitable end of arm tooling specific to the process.

Vision Inspection System

An integrated vision inspection system assesses the quality and conformance of component parts as they pass through the VariPic™ system.

The vision system will utilise a camera to capture images of the component parts, before processing the images through specialised software which will decide whether a part is ‘good’ or ‘not good’.

The vision inspection system has been designed to complete 100% inspection and provide accuracy.

Integrated Control System with HMI

While the VariPic™ is taking care of the complicated automation, you can control the software with ease.

Having user-friendly software can yield several advantages such as fast and simple calibration and configuration.

Why choose a VariPic™?

In a word – flexibility. The VariPic™ was designed to assist customers who have multiple component variants, difficult to handle parts or have restrictions on available space.

Multiple Component Variants

Lots of variants of part to feed? No problem. An intelligent vision system comes as standard with the VariPic™, allowing a swift changeover.

Troublesome Components

Some components just do not want to feed efficiently – whether they naturally tangle, have few features to utilise for orientation or are simply ‘complicated’ in design. Using the in-built feeding and vision technology, the VariPic™ is designed to seamlessly neutralise all of these issues to provide the customer with a constant flow of parts.

Space Restrictions

At a maximum of L3000mm x W1100mm x H2000mm (including bulk hopper), the VariPic™ will take up less of your available floor space that a suite of bowl feeders.

Learn more about VariPic™

If you’d like to explore more about VariPic™, read our whitepaper. RNA’s VariPic™.

VariPic™ is a versatile automation system that handles various products and product elements in a selection of industries such as automotive, aerospace, medical, and electronics. It is a dependable and efficient system that can enhance productivity and quality and with RNA, you can have the bespoke solution that your company needs. Contact our team today to learn more about VariPic™.