Robotic Systems

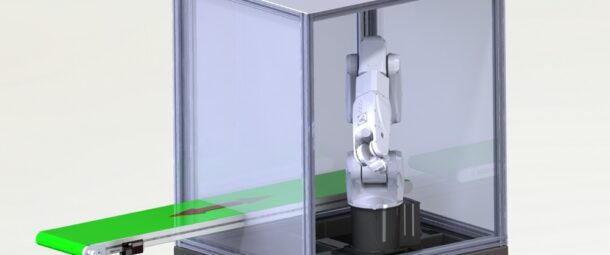

Flexible robotics and automation systems based on a standard platform to solve a wide range of handling tasks and with multi-industry applications.

Downloads

RNA Offer

- Robotic Systems Integration- Collaborative Robot Integration

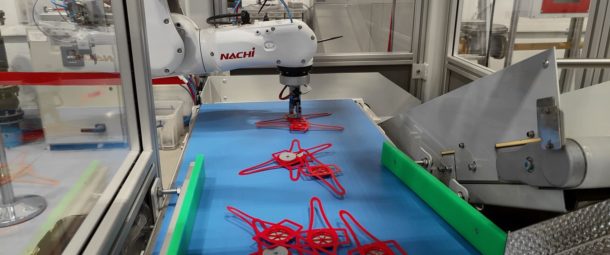

- Robot Clipping Systems

- VariPic™ Flexible Feeding

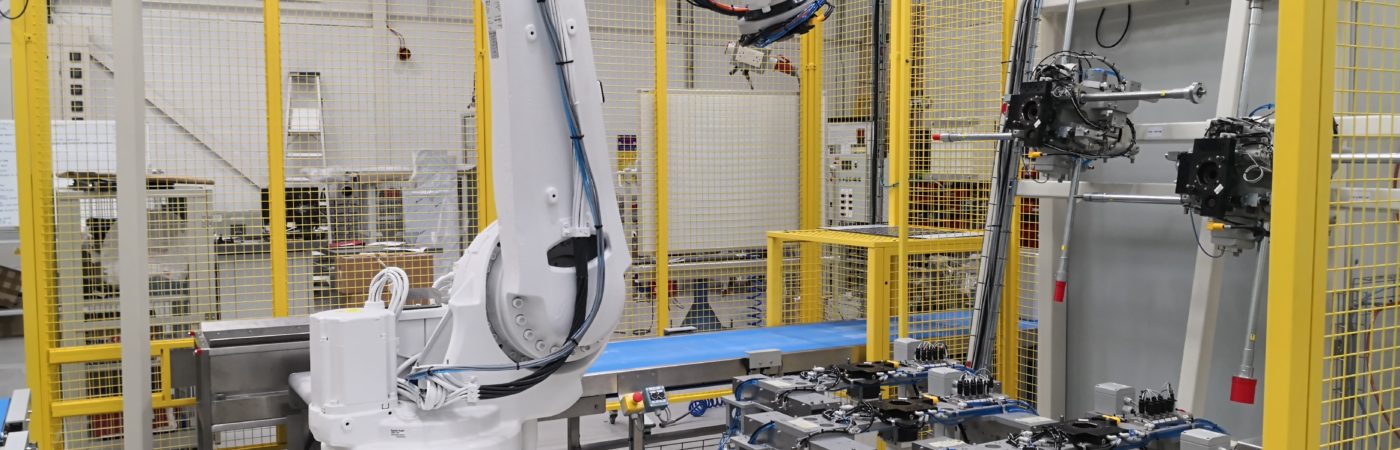

All robotic and automation systems have a robotic arm for handling and manipulating the products, a camera system (optional) and share the same PC based control system and in most cases integrated with a standard robot controller. The goals of custom automation are always based on the individual customer’s needs.

RNA Range RNA provide standard and custom robotic systems.

What Robotics and Automation Systems Can Offer?

RNA robotics and automation systems can offer low cost, high mechanical reliability, excellent versatility and short cycle times with a wide variety of components. An installed system is easy to operate and has the added benefit of a short set up time between products. The shortest possible payback time and minimal operator intervention are at the forefront of all RNA systems. With the RNA system, it is possible to automate small or large batches and achieve good profitability even with annual volumes as low as a thousand components. The RNA system philosophy is to deliver a system that is “Future Proof”.

Part Presentation Solutions

- Feeding Systems

- Jigs

- Trays

- Boxes & pallets

- Vision systems

- Conveyor belts

- 3-Axis Vibration Platforms

Types of robot RNA use

- 6/7 Axis

- SCARA

- Vision Guided

- Collaborative

Industrial Robot Applications:

- Assembly

- Material Handling

- Palletising

- Picking & Packaging

- Vision Inspection

- Welding

- Machine Tending

- Press Tending

- Part Transfer

- …and more

Applications

Contact

Send your message to a member of our team

Read our Privacy Policy to learn how we manage and protect your submitted information.