The world had to keep turning during the pandemic and the food industry had to keep producing. With many companies in the UK and globally turning to robotics and automation, RNA is here to tell you how are robotics and automation changing the food industry.

The world had to keep turning during the pandemic and the food industry had to keep producing. With many companies in the UK and globally turning to robotics and automation, RNA is here to tell you how are robotics and automation changing the food industry.

There’s been a 35% increase in robot and automation sales in the food industry since 2019 in the UK alone. With China surpassing their 198-million-dollar investment into robotics for the food industry (predicted for 2022), we have noticed a strong global persuasion to invest in automation to secure predictability of the food market as well as curve any labour shortages.

But why now? The obvious answer is COVID-19 and Brexit. The more complicated answer is the Ukrainian/ Russian war.

Like with most global, national disasters, the economy is forced to innovate and adapt to meet demand irrespective of rising costs, access to supplies and of course labour. If you haven’t heard about the labour shortage and its incredible impact on the food and beverage production line, you might want to take note.

There’s a clear reason why companies are seeing the benefit of plunging into huge initial investments in bespoke automation for their production line and that’s due to them wanting to limit risk. The offering of a highly skilled workforce just simply isn’t there after Brexit and with many companies cutting European ties, the UK has had to innovate by looking closer to home. In hand with our European partners breaking long-standing partnerships with us in the UK, we’re seeing a vast swelling of European companies taking up opportunities in the US.

With self-sufficiency at the core of the UK food and beverage market, automation and robotics have given companies the autonomy to produce intricate, quality consistent, and efficient solutions with the help of experts such as RNA.

How are robotics and automation used in the food industry?

The most striking way in which robotics and automation are used in the food and beverage industry is their assurance of return on investment. In addition to that, the practical workings of robotics within the production line and beyond are astonishingly clever.

It’s important to understand that automation engulfs an array of varying moving parts, functions and deliverables. Within RNA’s bespoke automation, multiple tasks are being performed. From vision inspection and quality control to picking and placing to packing and palletising, automation can be found at every step of production.

What are the benefits of automation in the food industry?

Robotics used within RNA’s specially designed automation allows each company to meet the needs of their production line with greater efficiency.

Easier to operate

As the food and beverage industry over the past 5 years has adopted more and more automation in-house, it has become increasingly apparent that changing programming, adapting the process and adjusting various dimensions, and commands are just simply easier.

Huge single-purpose robots of the 90s would often only conduct one function, be a huge task to update or fix and were usually difficult to move and reposition.

With intelligent bespoke programming and technical support from RNA, the ability to update the reporting and delivery program of your specially designed automation just became even simpler.

Reduces errors

In the food industry, the cost of errors can be significant. However, the use of robotics and automation is helping to reduce errors and improve overall quality.

With the sophistication of technology like RNA’s bespoke automation, fine details can be picked up during the production process that may have been missed by humans.

Advanced sensors and cameras are used to detect defects, ensuring that faulty products are removed from the production line before they reach the market. Automation also eliminates the risk of human error, which can be caused by fatigue, distraction or other factors.

Cobots allow safe collaboration

Collaborative robots, or cobots, are changing the way the food and beverage industry operates.

One of the key advantages of cobots is their ability to work safely in collaboration with humans. They can be programmed to perform tasks that are repetitive, dangerous or require precision, freeing up human workers for more complex and creative tasks.

Cobots are also designed with advanced safety features, such as force-limiting and speed-limiting technology, which ensures that they can work alongside humans without causing injury.

By allowing safe collaboration between humans and robots, cobots are transforming the production line and helping companies to increase productivity, reduce costs and improve overall efficiency.

What are examples of how robotics and automation are used in the food industry?

With the food and beverage industry’s needs being vast and varying, companies are using robotics and automation to nurture their efficiency and increase revenue.

There are many examples of how robotics and automation are used in the food industry, from processing and packaging to quality control and inspection. Here are a few examples:

- Automated sorting systems: These systems use cameras and sensors to sort fruits, vegetables and other products based on size, shape, colour, and other characteristics.

- Picking and placing: Vision Guided Robotics are used to pick and place products on the production line, which reduces the need for manual labour and increases efficiency.

Automated Production Line for Salad ‘Easy Meals’

A Vision Guided Robot catches and determines the exact position of the sauce sachets. Then, it picks up one sachet at a time and places it into the salad trays waiting on the parallel belt conveyor. ►

- Quality control: Automated inspection systems can detect defects or contaminants, which helps to improve overall quality and safety.

- Packaging and palletizing: Robots can be used to package products in containers, boxes or bags, and then palletize them for shipping.

- Food decoration and Assembly: Automated food decorating robot, precision food assembly machine, robot icing dispenser, confectionery assembly robot.

- Cooking and preparation: Some companies are using robotics to prepare and cook food, such as pizza-making robots or automated burger-flipping machines.

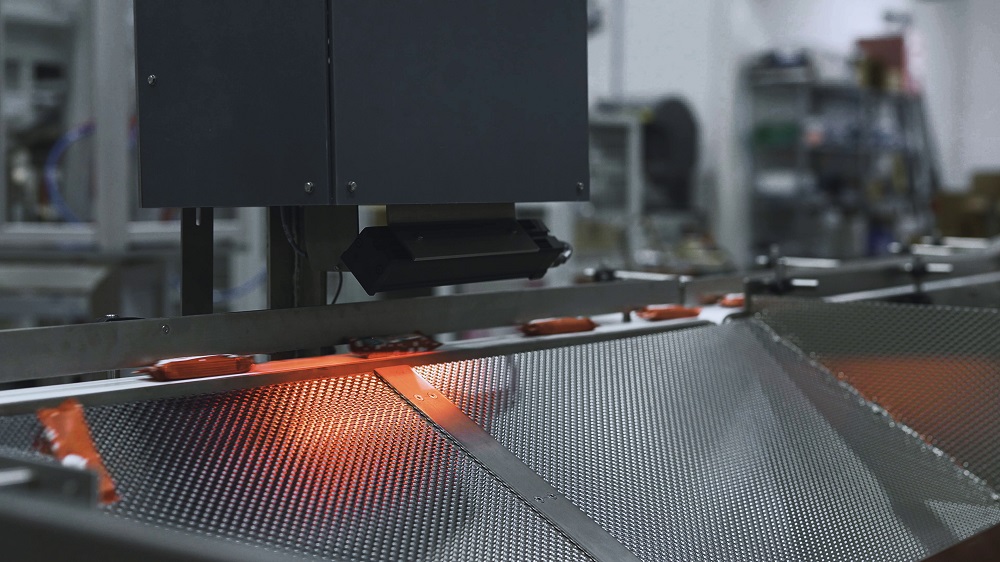

VariFeed® Flexible Feeding System for High-Speed Packaging Applications

The system provides easy and speedy changeovers for multiple products, essential when handling an assortment of confectionery such as chocolate bars, protein bars and cereal bars. ►

These are just a few examples of how robotics and automation are transforming the food industry, making it more efficient, safer, and able to meet the demands of consumers.

Why you should use robotics and automation for food manufacturing

Not only do RNA robotic solutions help increase productivity, but they will also combat the labour shortage. The move to automation has brought companies out of the doom and gloom of the economic crisis and into the light of seamless production.

Consistency with reporting and output is desirable to stakeholders. So when you think of automation, think about the future and where your food manufacturing company wants to be in a few years. While the food and beverage industry is more than dipping its toe into fully automated conditions, it poses the question of how RNA can help you today.

Get in touch with RNA to explore and discover our range of automation and robotics that will propel your production line into the future. Call RNA at +44 (0)121 749 2566

Last edited on: November 2, 2023