Solution

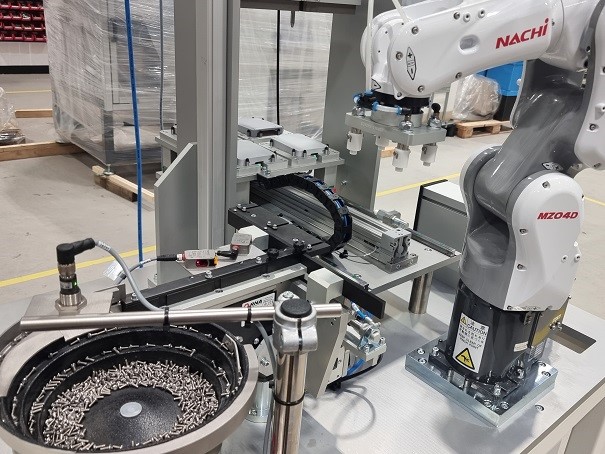

The robot assembly system is mounted after the laser printing station. The screw heads are sheared using an air operated driver with a compliant head mounted on a small 6 axis Nachi Robot. The sheared heads are removed by the robot using vacuum and deposited into a chute as waste.

The square and round plastic bungs for the new type meter are fed using individual bowl feeders to dead nests. The robot assembles the bung into the appropriate slot on the meter housing. Additional plunger mechanisms are included to ensure the bungs are fully assembled into position.

Key features

- Nachi MZ04 Robot

- Robot mounted air operated screwdriver with compliant head

- Robot mounted vacuum head

- Square bung bowl feeder with linear track and dead nest

- Round bung bowl feeder with linear track and dead nest

- Waste screw head chute

- Guarding

- Control system