Solution

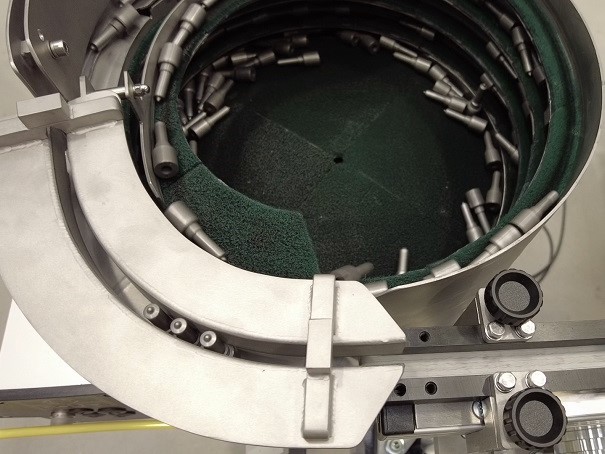

The system consists of four stations. The first station includes an assembly side of fuel pick up pipe with an automated flash check and leak testing system. A dot mark will be applied to

the verified pick up pipe, and the operator removes rejected parts into the reject chute. At the same time, the tank has 5 automated flash checks and hydraulically inserts 3 bushes on the other side of the machine.

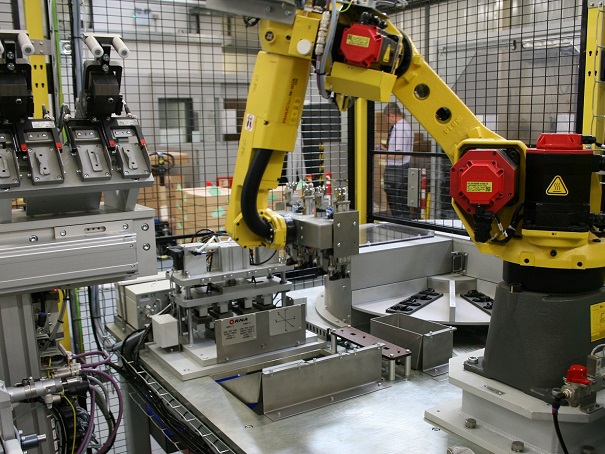

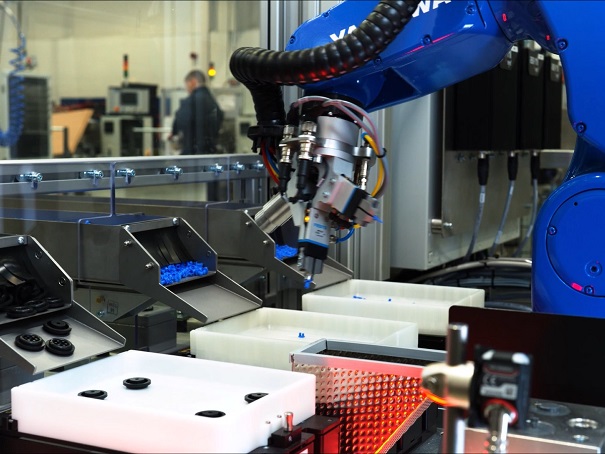

The second station includes a manual fixture workstation and an automatic assembly and verification system. Operator loads fuel tank to a custom fixture on the assembly and

verification system. This has been pre-assembled on the workstation of the fixture with 14 bushes, 2 nuts, 1 clip and 1 fuel pick up pipe assembly. 2 starlock washers are also loaded to the fixture, and then a hydraulic press operation starts to automatically install parts to the fuel tank. Poka-Yoke details and dedicated sensors ensure all parts are accurately presented and fully inserted.

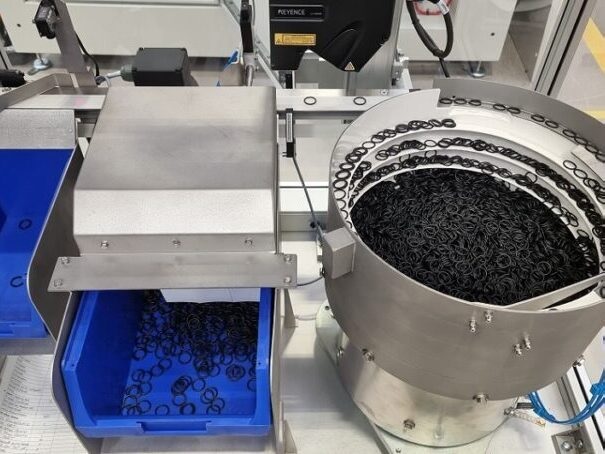

At station three, the operator firstly loads fuel tank to the gasket assembly fixture and fits gasket manually to the flange of the tank. Operator then screws O ring plugs into the fuel tank assembly at 2 positions. A pressure test station is utilised as a Poka-Yoke device to sense the O ring plug is present at the start of the process. If the O ring plug is not there, it alerts the operator before he/she can process.

The last station performs air pressure decay leak testing on the complete assembly. Operator loads fuel tank upside down to the fixture and the tank is pneumatically clamped ensuring proper part location. On the completion of the leak test cycle, if leak test passes, sensor detects tank colour and confirms it matches selection, and then operator apply a printed barcode label to the passed tank. After barcode reader checks label, ‘good’ tank will be dot marked and manually removed from the system. If leak test fails, HMI indicates failure.

Operator removes failed parts from fixture and takes to ‘reject parts station’. For this particular project, Poka Yoke is crucial to the assemblies and critically controlled within the whole production process. Mistake proofing techniques including fixture design, sensors, pressure test station and dot marking are used to prevent errors committed by operators. They allow the mistake to be corrected and solved without delay.