Solution

The Poka Yoke designed in the workstation consists of a Poka Yoke clamp and a Poka Yoke vision sensor. If the product does not match the build requirements the clamps will remain locked and the HMI will request a supervisor to attend.

The Poka Yoke designed workstation helps workers to be ‘right first time’, enhancing the quality and overall output of the process.

RNA design and build custom workstations to suit the individual needs of our customers.

If you are interested in more details in RNA custom workstation please contact us.

Operation Description

- Operator will load the LH or RH Carpet Gap Hider into the formed nest and activate part locking clamps.

- Operator will scan the barcode that states what colour the product is (this will be done at the start of every batch – batch size can vary).

- If accepted the machine will print off the correct label and the operator will apply to the part.

- The clamps will be released and the part can be removed from the fixture ready.

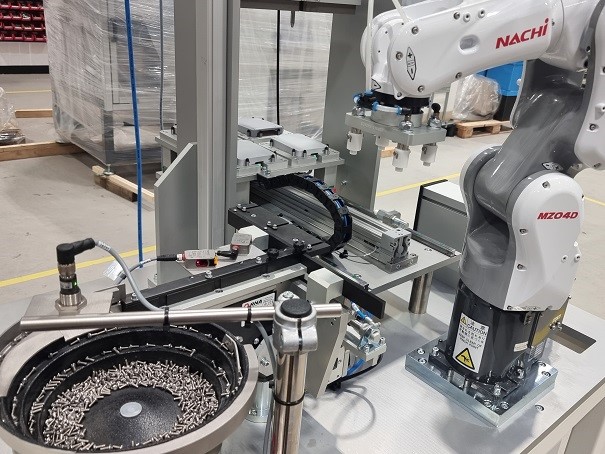

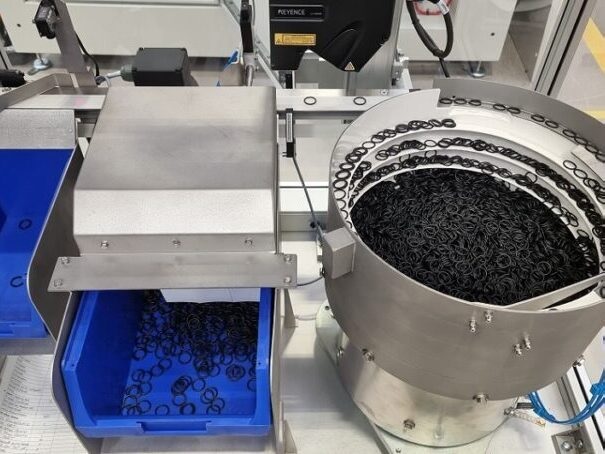

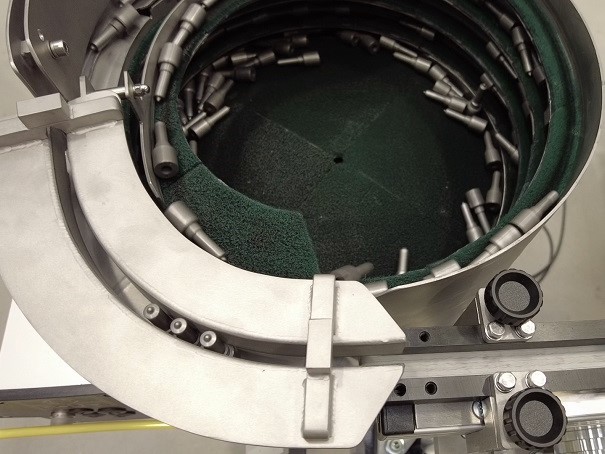

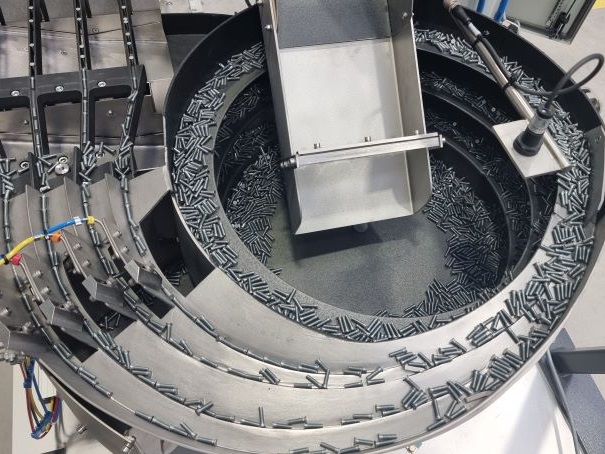

Elements of the workstation

- Workstation frame with light and socket

- 1+1-imp nesting

- Poka Yoke clamping

- Poka Yoke vision sensing

- Part present sensing

- ABS plastic back present

- Scanner & Printer

- System Control