Product:

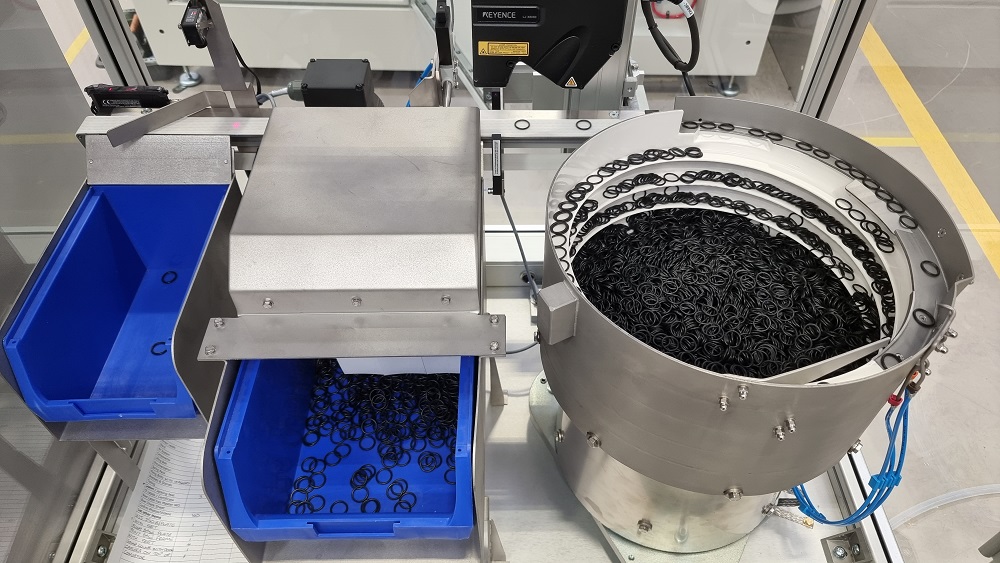

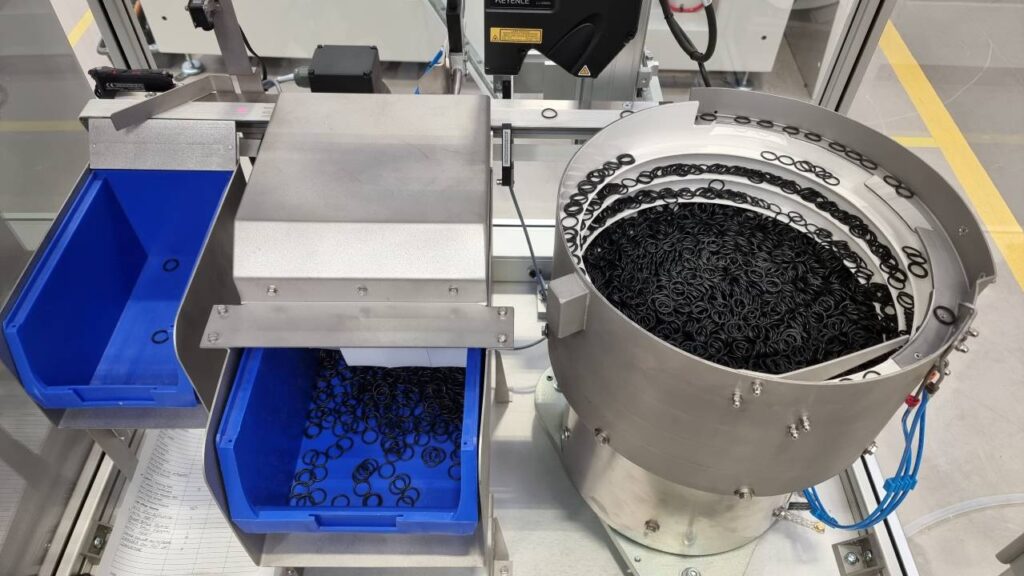

O-Ring

Solution:

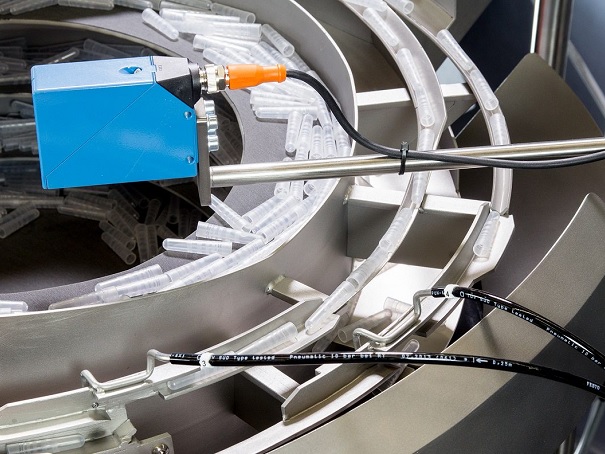

The O-Rings are fed and orientated by a bowl feeder, and then are discharged from the feeder to the conveyor out-feed. An inline laser profile inspection station is fitted with the conveyor out-feed to check o-rings dimensions as they pass through. Good parts will be identified and positively transferred from the conveyor via a gravity chute to a storage container (Good); Bad parts will be identified and allowed to transfer to a second storage container (Bad).

Speed:

50 inspected components per minute.

Scope:

- Bowl Feeder

- Conveyor Out-feed

- Inspection Station – Laser Profiler

- Acoustic Cover

- Control System complete with HMI

Key features:

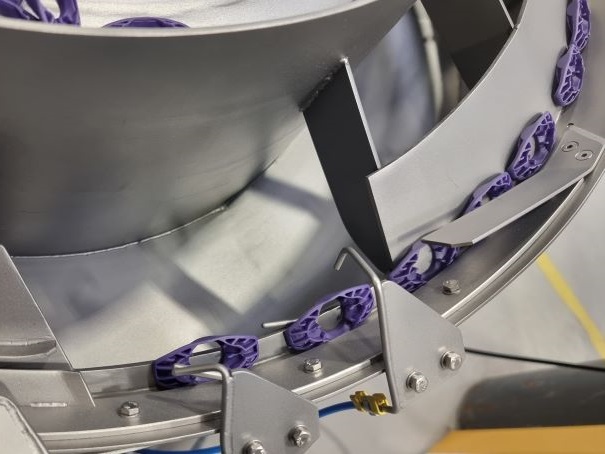

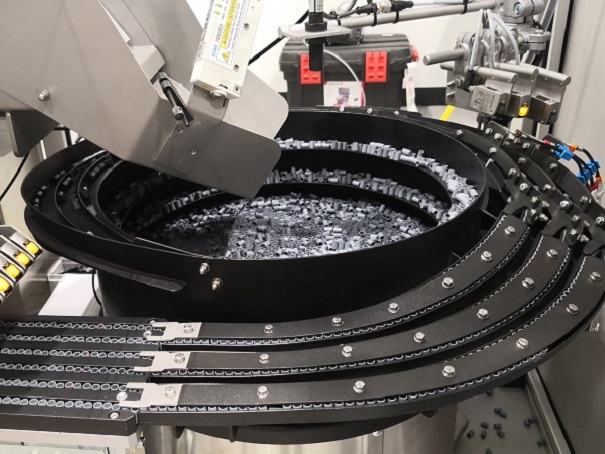

- Cylindrical bowl

- Stainless grade 316L

- FDA approved polyurethane

- Smooth and gentle handling

- Low noise level

- Pharmaceutical design

Pharmaceutical design

RNA manufacture and supply bowl feeders for the clean room and sterile conditions, constructed from 316L grade stainless steel for handling pharmaceutical products.