Product:

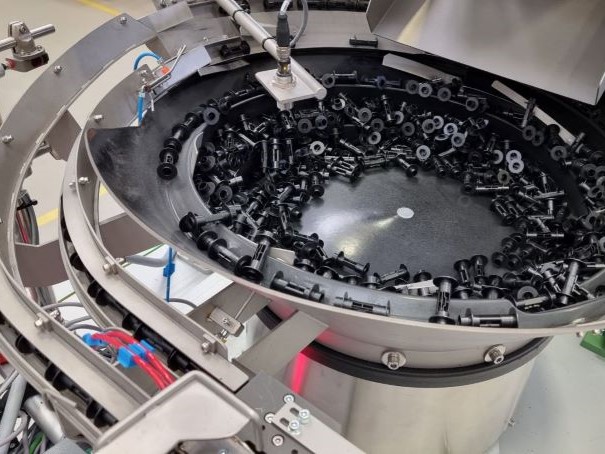

Fasteners (Stud and Nut M5/M6/M8)

Orientation:

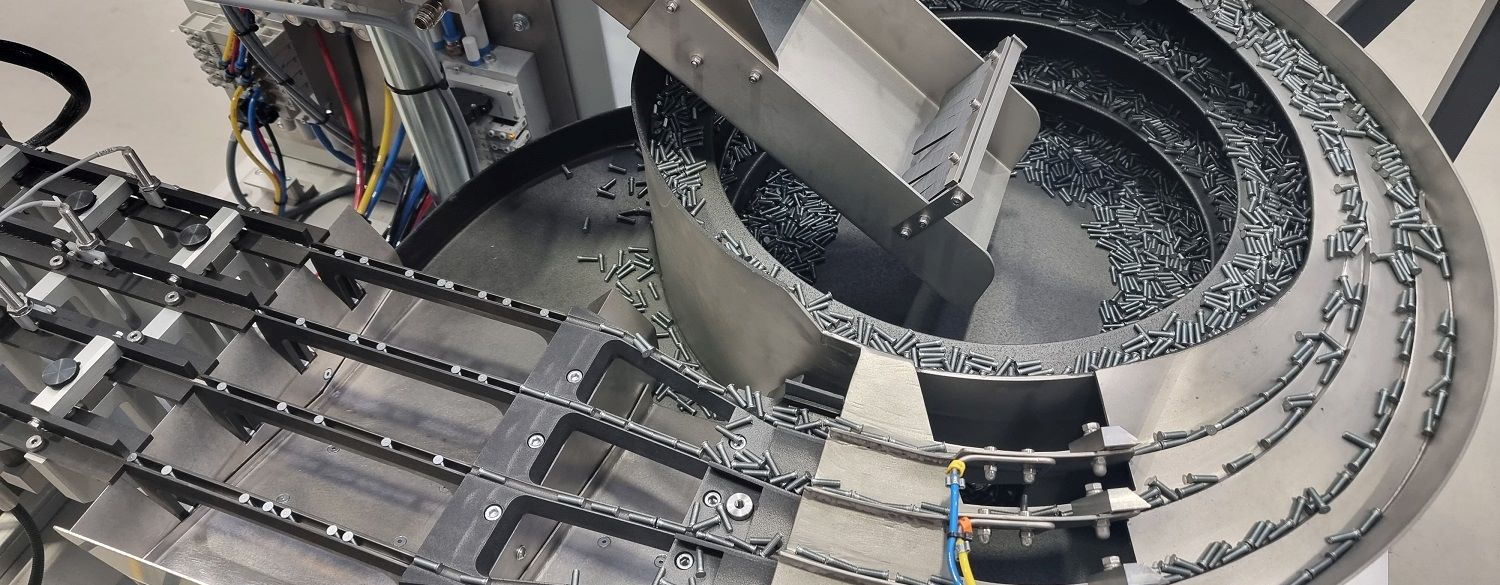

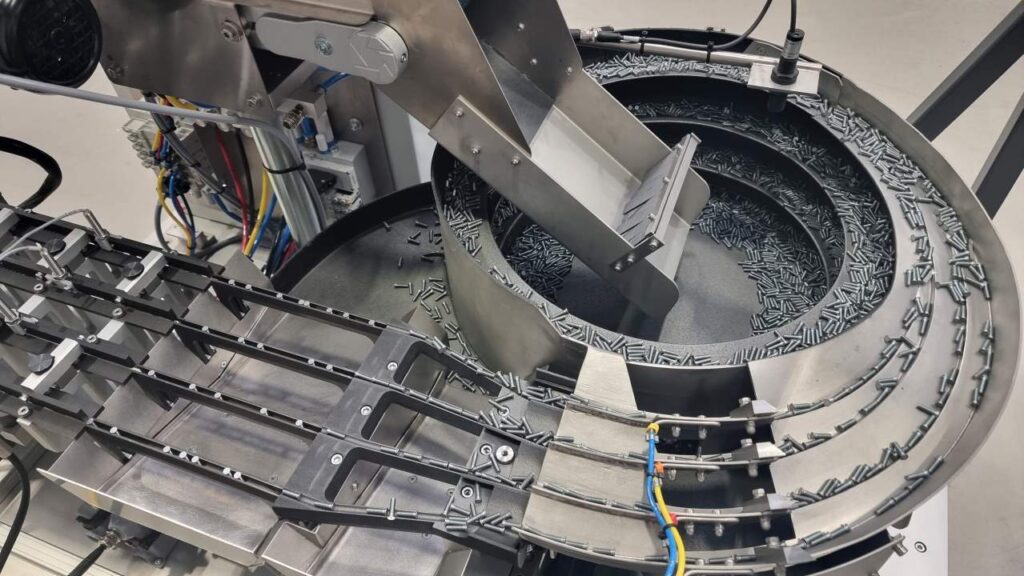

Component parts to be blow fed from 4 lanes at a pitch of 60mm

Speed:

Up to 60 components per minute per lane

Scope:

- Bulk storage hopper

- Cylindrical Bowl top – Fitted with a purge gate to aid part changeover

- Bowl Feeder drive unit

- Control Box

- Linear Feeder

- Side Shuttle Blow Feed Escapement

Key features:

- Cylindrical bowl

- Heavy duty polyurethane coating

- Multi lane tooled track

- Easy part changeover

- High speed feeding

- Smooth and gentle handling