Solution

For this particular project the system were required to fit 15 clips per side panel and weld one reinforcement panel per hand per cycle. RNA have developed an automatic robotic assembly system for clipping and welding incorporating a clip insertion robot, a welding robot with ultrasonic welding head, a bowl feeder system and a control system.

For this particular project the system were required to fit 15 clips per side panel and weld one reinforcement panel per hand per cycle. RNA have developed an automatic robotic assembly system for clipping and welding incorporating a clip insertion robot, a welding robot with ultrasonic welding head, a bowl feeder system and a control system.

The Challenge

In designing the system a number of challenges were highlighted:

- The project was required to have a complete cycle time of less than 120 seconds including load and unload time.

- Component parts with shape variation

- The project needed to ensure precise positional accuracy for the clip placement and the reinforcement panel welding.

Two work as a team

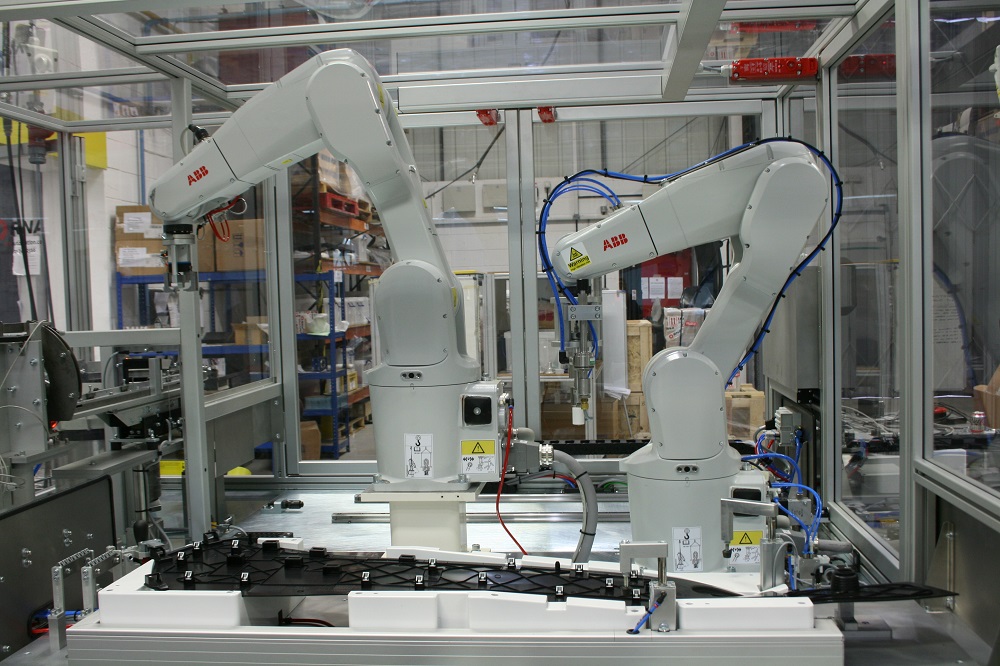

Working in close cooperation with our customer, engineers at RNA selected two six axis robots to carry out all the requisite processes.

To start the process, the console side panel and the reinforcement panel are manually loaded and clamped onto a sliding table by the operator and pushed into position. Robot 1 picks and accurately loads 15 lips onto the side panel, while robot 2 ultrasonically welds and joins the reinforcement panel to the side panel. The cycle time was optimized by having both robots work simultaneously to complete the clip placement and ultrasonic welding. To complete the process, robot 1 dot marks the ‘good’ side panel, adding poka-yoke (error proofing) and assuring traceability.

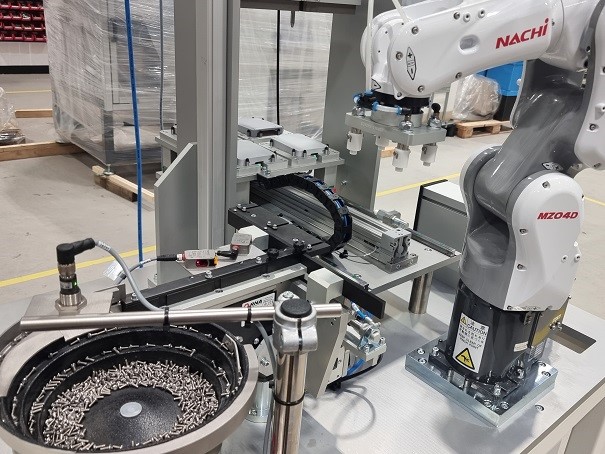

Upstream of the robots, clips are fed and orientated via a vibratory bowl and linear feed system to a precession shuttle mechanism so that the clip is always in a known repeatable and accurate positional location for the robot to pick up.

Once the robots have conducted their tasks the operator pulls the sliding table out and the cycle completes.

The system has independent right and left hand sliding tables, each including a mirrored assembly fixture for a LH or RH side panel. While the operator is unloading and reloading one side, the other side is being processed by the robots. The mirrored feature allows for increased productivity due to fast lead time and the inherent repeatability and efficiency of the robotic process.

A human-machine interface (HMI) is integrated, giving instructions to the operator and enabling easy configuration of parameters and monitoring of the whole operation.