Scroll

Consumer Goods

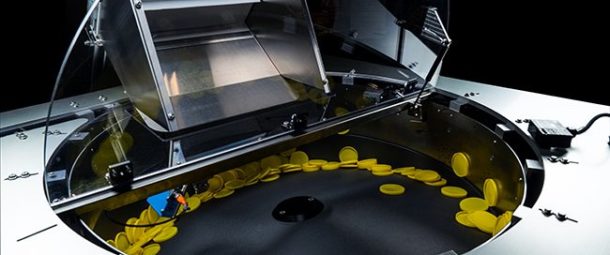

Custom Automation Systems for consumer goods manufacturing

Introduction

To ensure continued success and profitability, integrated and automated manufacturing with high-speed conveyors, collaborative robots and other automation technology can complete processes faster and more accurately. RNA has a wealth of experience in providing tailor-made, sustainable automation solutions for the consumer goods manufacturers.

The technologies used within our automation solutions:

- Automated Parts Feeding & Handling

- Robotics/Collaborative Robots

- Vision Inspection & Quality Control

- Pick & Place

- Assembly

- Packaging & Process

- Many more…

Solutions