Vision Inspection Systems

Reliable, accurate high speed solutions from a single source supplier. RNA automated vision inspection systems are turnkey solutions for total confidence of supply.

Downloads

RNA Offer

- Vision Systems Integration- Vision Quality Control

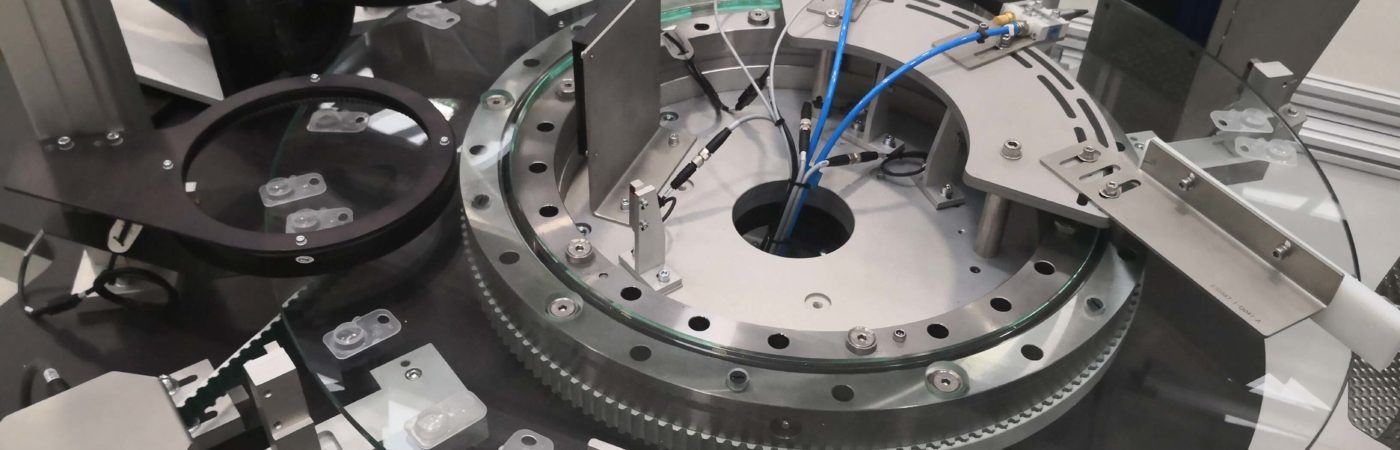

- MK360™ Glass Disc Vision

- Poka-Yoke Design

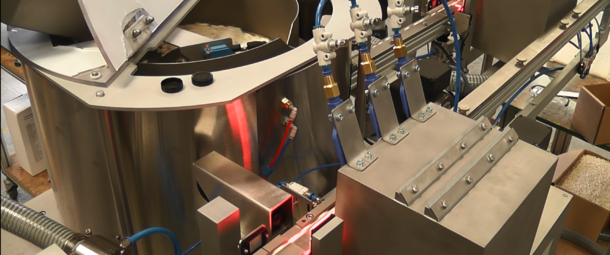

From a vision inspection system for checking out of tolerance components, counting systems for bagging machines, utilising the latest pneumatic and electric linear slide systems RNA can supply a system to move, manipulate and handle your components.

RNA Range RNA provide standard and custom vision inspection systems.

Why RNA Vision Inspection System

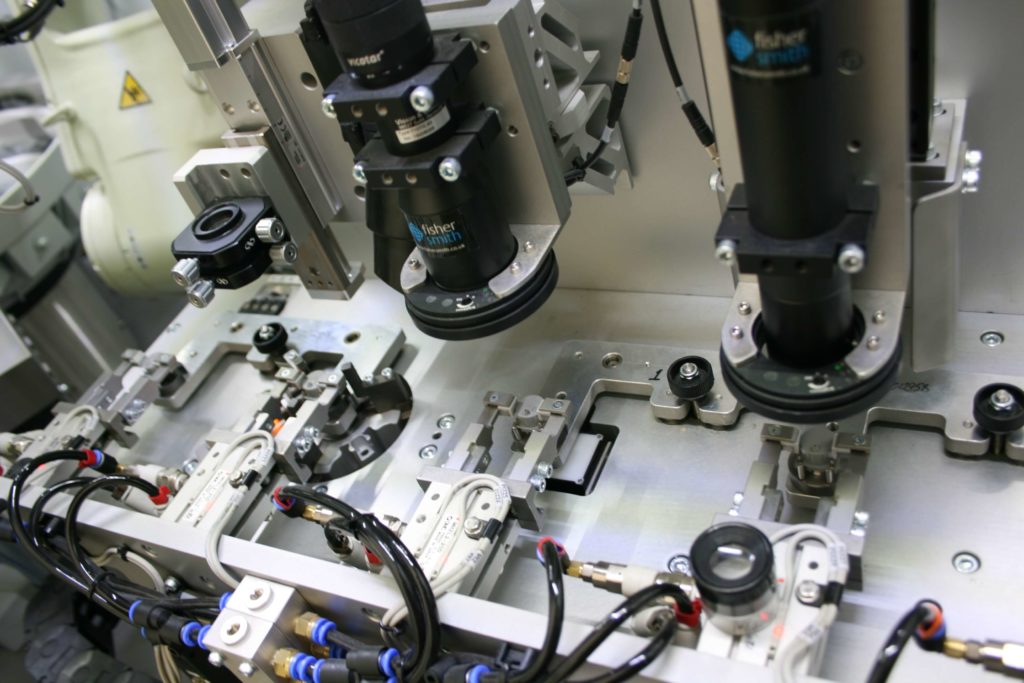

- In house integration of a wide range of camera technology to provide the right solution every time.

- Full technical support with remote diagnosis capability.

- Front end feasibility studies for complete peace of mind.

Applications of vision system include:

- Presence/Absence detection

- Defect detection

- Automated vision test & measurement

- Pattern matching

- Vision guided robot

- Part verification (orientation, function, dimension, finished part features)

- Optical character recognition & verification (OCR/OCV)

- Colour verification

- Sorting

- Barcode reading and traceability

RNA have experience of inspecting components down to 0.02mm ,and have supplied camera systems to inspect for surface defects, sort components into batches for colour and size and also for orientation purposes where a mechanical solution cannot be used.

Our in-house engineers will supply a custom software package and PLC control to suit each system requirement. All standard platforms of PLC operating software and hardware can be catered for.

Our experienced team of specialists are available to provide advice and to offer a solution which meets your specific needs.

Applications

Contact

Send your message to a member of our team

Read our Privacy Policy to learn how we manage and protect your submitted information.