MK360™ Vision System Feeds and Inspects Pharmaceutical Ferrules

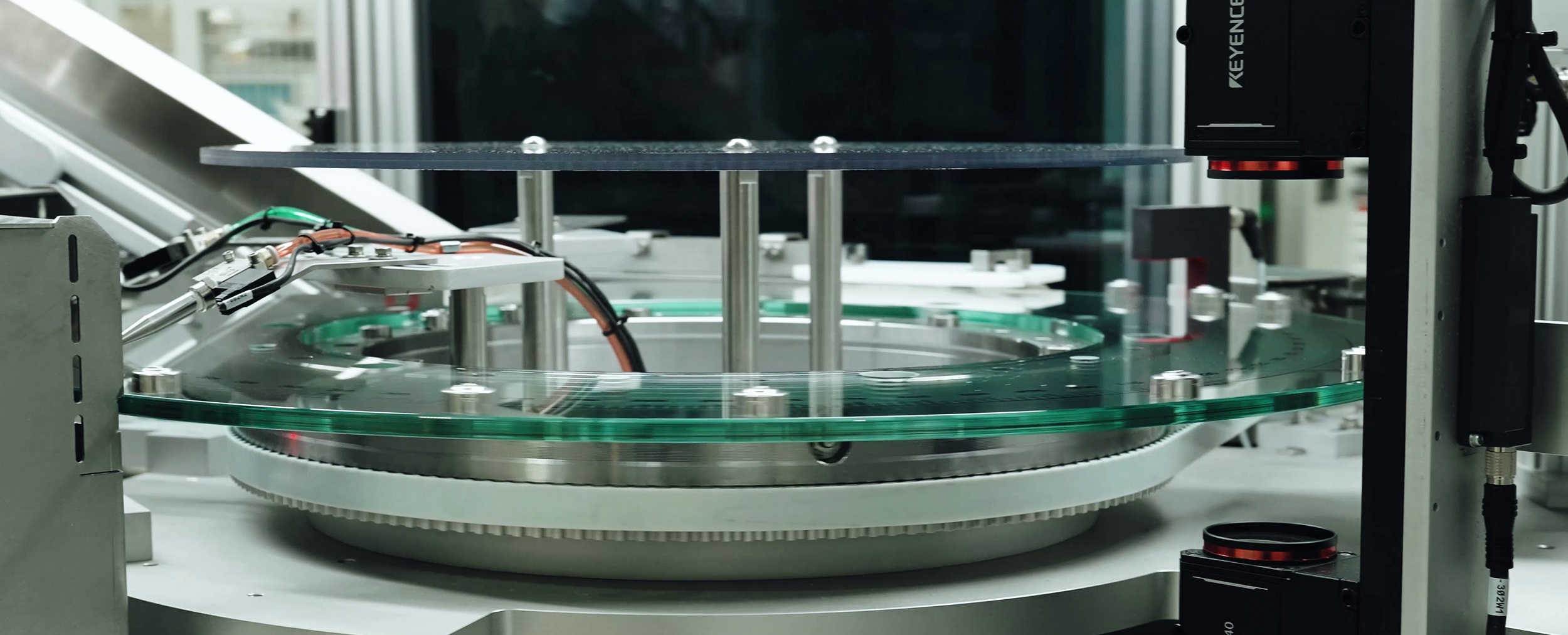

The RNA MK360™ glass disc vision machine is developed specifically for 360° quality inspection. A unique and novel approach to inspecting through the use of a rotating disc.

Solution

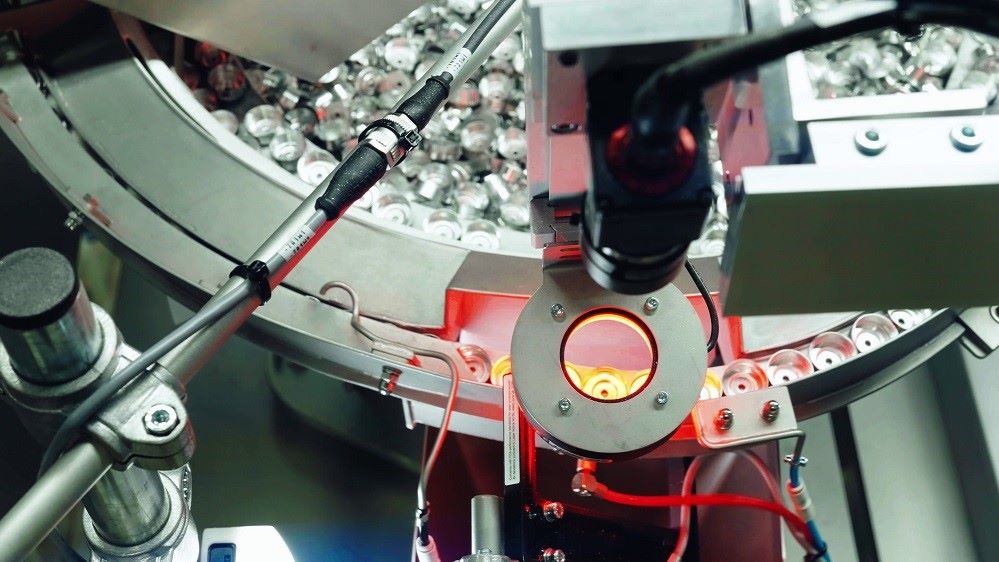

The ferrules are fed from a vibratory bowl feeder, onto a conveyor system and fed individually onto a rotating glass disc, where they are presented to the 3-camera system.

Component parts are checked for roundness and diameter of the ferrules, and for anodised/non-anodised surface finish.

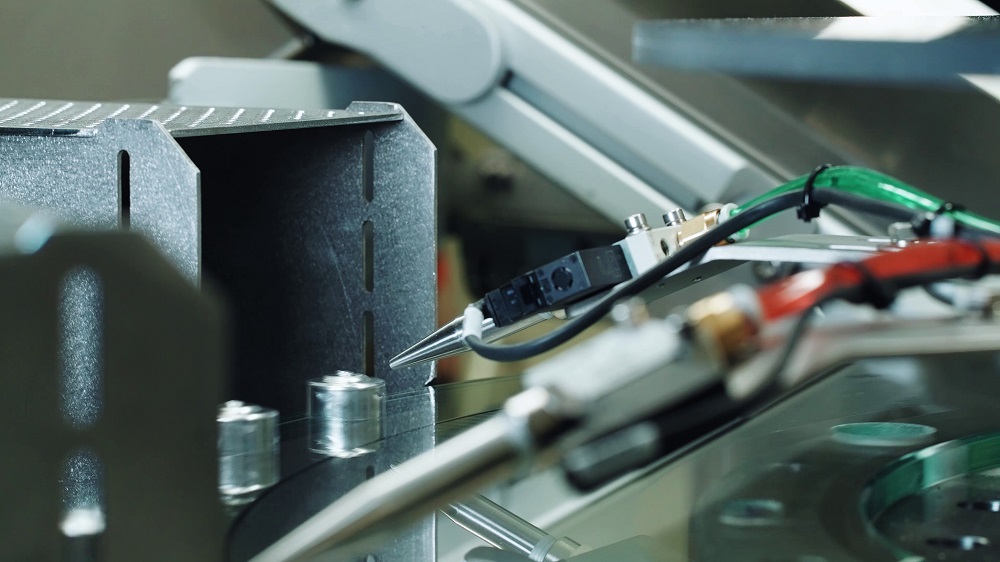

An air blast complete with control solenoid valve removes individual ‘good’ components from the disc into a chute; remaining ‘reject’ components continue round the disc being gently ejected from the wheel down a chute into a collection box.

Key features

- Bulk Feeder BFK 65

- Bowl Feeder TAG-ZA 400

- FDA 400 polyurethane coating

- Transfer Conveyor

- Inspection wheel with Good/Bad Ejection

- Control System complete with HMI

Other Case Studies

Contact

Send your message to a member of our team

Read our Privacy Policy to learn how we manage and protect your submitted information.