Solution

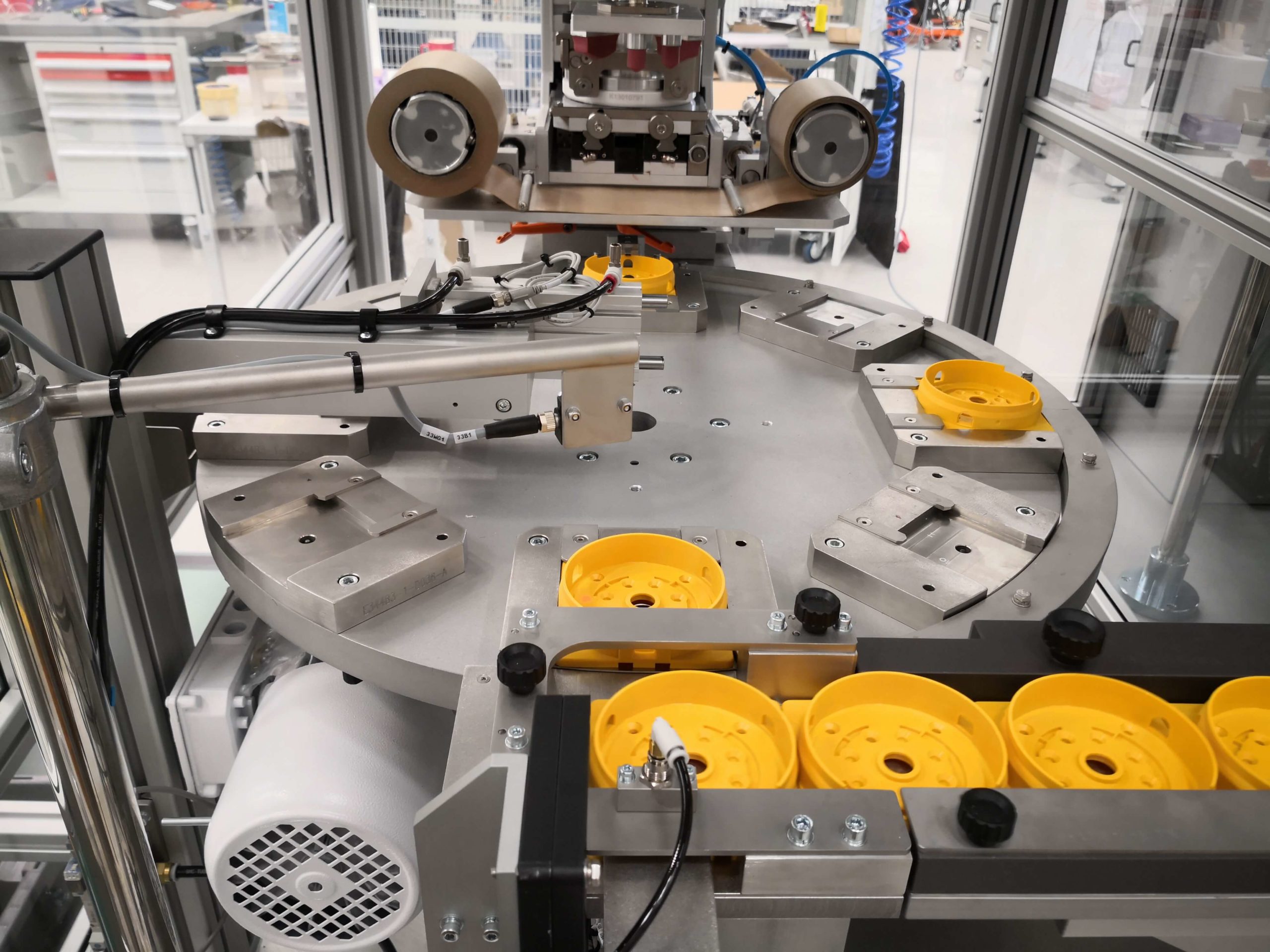

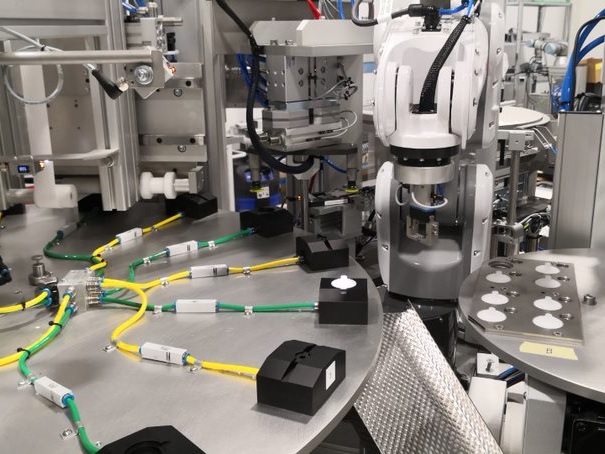

The operator loads switch bodies into and elevating bulk feeder, which stores and transfers them to a vibratory bowl feeder. The switch bodies are then fed and orientated by the bowl feeder to a vibratory linear track, which is fitted with a pneumatic escapement to push one part at a time onto a 4-station rotary indexing table. The rotary indexing table presents switch bodies to an Alien 130 high speed pad printer for the pattern to be applied in a single colour. The indexing table then moves the printed parts to an ejection station to be transferred via a chute into the customer’s storage containers.

The machine is designed for two variants of switch body. Changeover between the two variants is achieved via quick release change tooling and a 2-position switch on the control system.

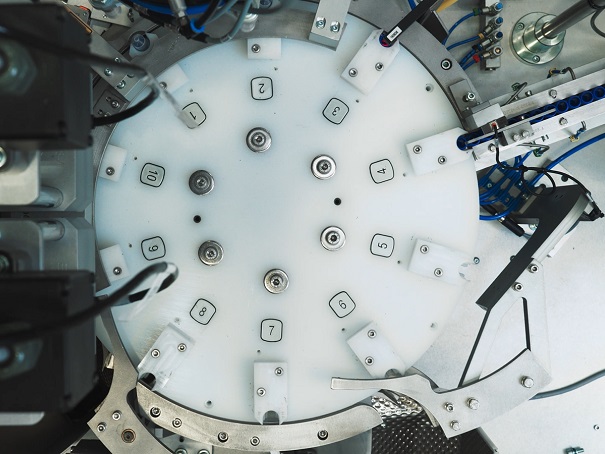

RNA design and develop rotary indexing system that is tailored to the customer’s specific applications. The system can be utilized in many environments ranging from assembly, machining, testing, printing to parts positioning and transfer. Part feeding and handling, pick and place and vision inspection can be integrated for semi or fully automated operation.