Challenge

For this particular project a sauce sachet and a spork (foldable spoon & fork) were to be placed into a salad tray. RNA was commissioned to develop an automated handling system to present loaded salad trays into a tray sealer at a speed of 50 trays per minute. The solution chosen was a vision guided robotic system equipped with a sachet loading system, a spork loading system and transfer conveyors.

One of the major considerations in this project was the nature of the sauce sachets: soft, non- uniform in shape with a gloss surface. The challenge was going to be ensuring the sauce sachets were in the right position for a vision guided robot cell to pick and place with accuracy. The complex shape of the sporks also brought about challenges with the handling system.

Additionally, the customer required a complete system with minimum requirements below:

- The system must be designed to meet food and GMP standards.

- The system including the robot must be suitable for a wash down environment and subject to daily cleaning with a high pressure water spray.

- The system must be flexible to allow a range of different sized sachets & coloured sauces to be accommodated.

Solution

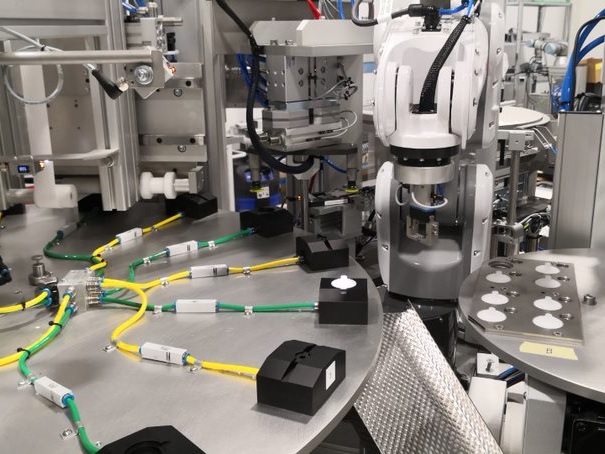

To automate the process of salad tray filling, RNA has developed an automation-friendly system that included a tray denester to load one tray at a time onto the transfer conveyor, a bespoke sachet handling system to separate and present sauce sachets to a vision guided robot, and a vibratory handling system to orientate and release one spork at a time into a tray.

In the system, two food grade transfer conveyors carry the trays and sauce sachets separately in parallel. A conditioning roller flattens the non-uniform shaped sachets into a pickable condition. Upstream of the robot is a camera system to catch and determine the exact position of the sauce sachets. Once the position is determined, the robot is guided to pick up one sachet at a time and place it into the salad trays waiting on the parallel belt conveyor.

The filled trays then move downstream to the spork loading system where a vibratory bowl feeding system equipped with a ‘Tic-Toc’ escapement to load the sporks one by one into the trays. The trays are then transported via a transfer conveyor to the operator zone. Up to five operators work alongside the conveyor and manually add the appropriate ingredients into each tray before being transported into the tray sealer.

Allen Bradley CompactLogix PLC and human machine interface (HMI) are integrated to fully control the whole system. With a custom graphical interface designed, teaching the system (reprogramming a new component) takes just a few minutes, providing the system with future proof automation.

The system features a robust frame of stainless steel and FDA approved materials. PLC and robot controller are enclosed within an IP65 stainless steel cabinet.

The quiet and compact design offers a reliable, repeatable and highly productive solution, reduces manual handling by operators and offers a much more hygienic alternative. ‘RNA expertise in handling and presenting products to the vision guided robot which improve pickability & efficiency of the line.’