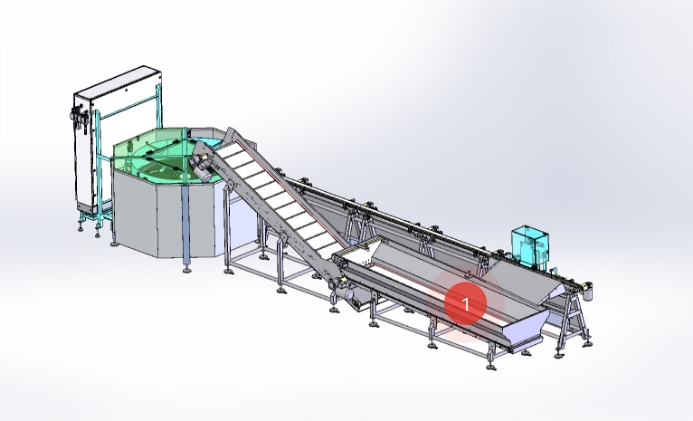

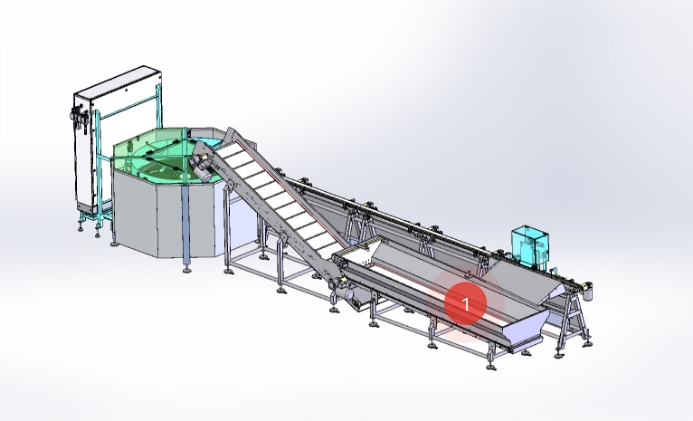

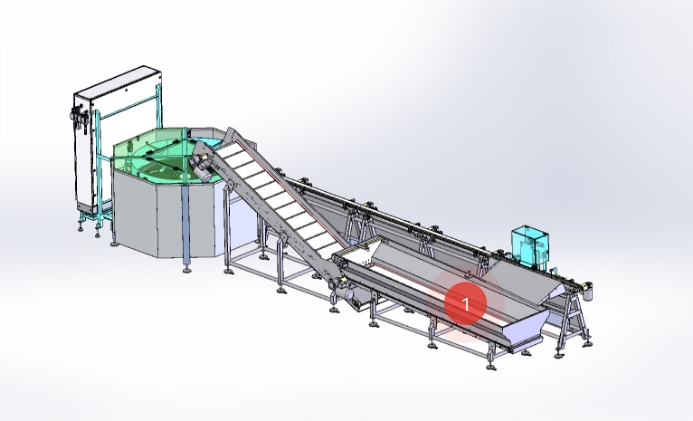

RNA’s VariFeed® is a high-speed, automated feeding system for handling a wide range of pouches, flow pack bags and other flexible packaging.

Feeding pouches and sachets in their many forms requires high speed automated systems that can handle the most demanding and challenging projects. High volume manufacturers and repackers need to mass produce and pack as efficiently and rapidly as possible; speed to market is paramount. So how do you choose the best automated feeding system for your production line?

Look for flexibility, high speed, simplicity of installation and operation, top quality construction – and of course a system that is future proof and will give you a rapid return on investment (ROI). It so happens that we have just the solution for you.

Its simple, modular design makes VariFeed® suitable for processes across different industries such as Chocolate and confectionery, Pharma and Healthcare, and Dry Foods. It can be easily configured to meet a customer’s specific requirements.

Send your message to a member of our team

Read our Privacy Policy to learn how we manage and protect your submitted information.