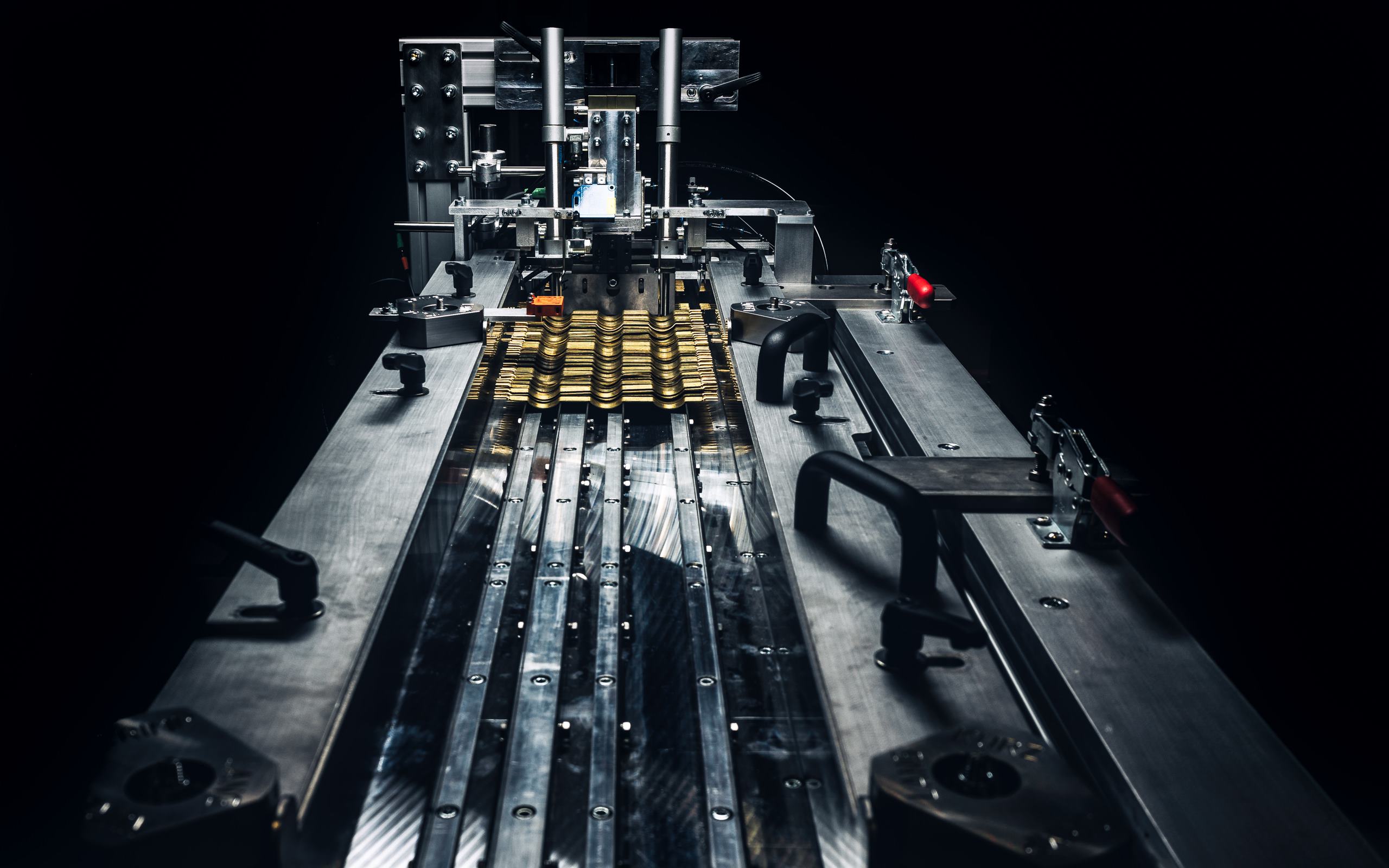

With the smooth movement from the SLL 804, the busbars gently slide along the linear track to reach the separating and accumulation linear feeder (the second linear feeder). An aligner station consisting of two hold back cylinders regulates the transported busbar stack, parallel to the axis, and then releases them when the sorting and separating station is free.

In the sorting and separating station, an exchangeable blade runs cyclically over the busbars. The busbars lying double or crossed are then pushed back by the blade as far as needed, until they are singulated. The cyclical movement is produced by two linear units (horizontal and vertical).

The busbars are now accumulated one behind the other onto two nests mounted at the end of the accumulation conveyor. Once in the nest, the busbar is clamped with cylinders and then separated with a swivelling movement into a horizontal position, ready for the customer’s handling system to pick and place the part into a housing of a multiple socket.

The system operates at a cycle output of 12 parts per minute.

With RNA’s well-proven linear feeder, the system accomplishes sorting, separating, accumulation and also the supply of up to 300 long parts in a single system. The system has the flexibility to handle various component parts by using an innovative quick-change tooling system, resulting in improved uptime and productivity. Get in touch with us to discuss your requirements and we will be happy to visit you and offer our professional advice.