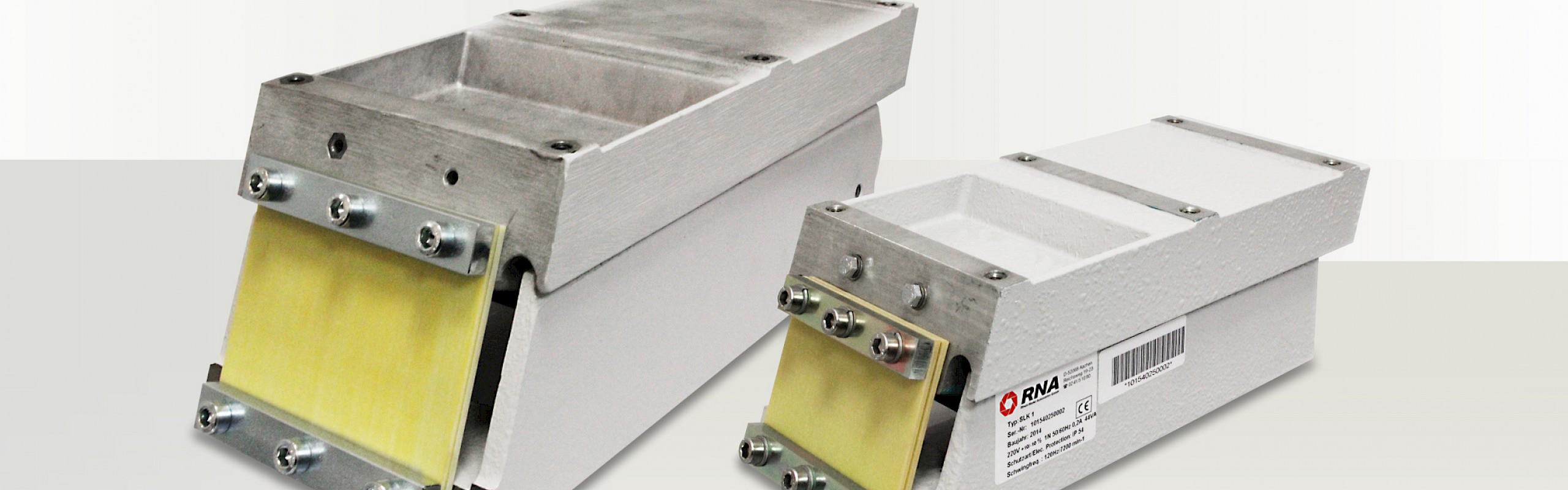

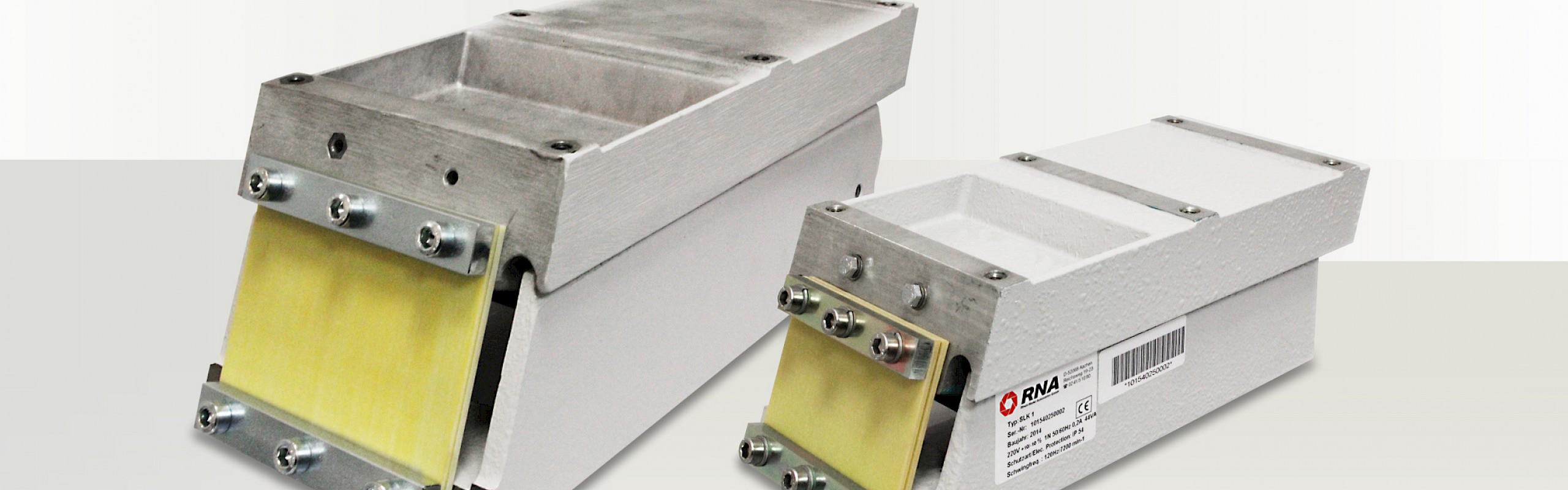

Linears

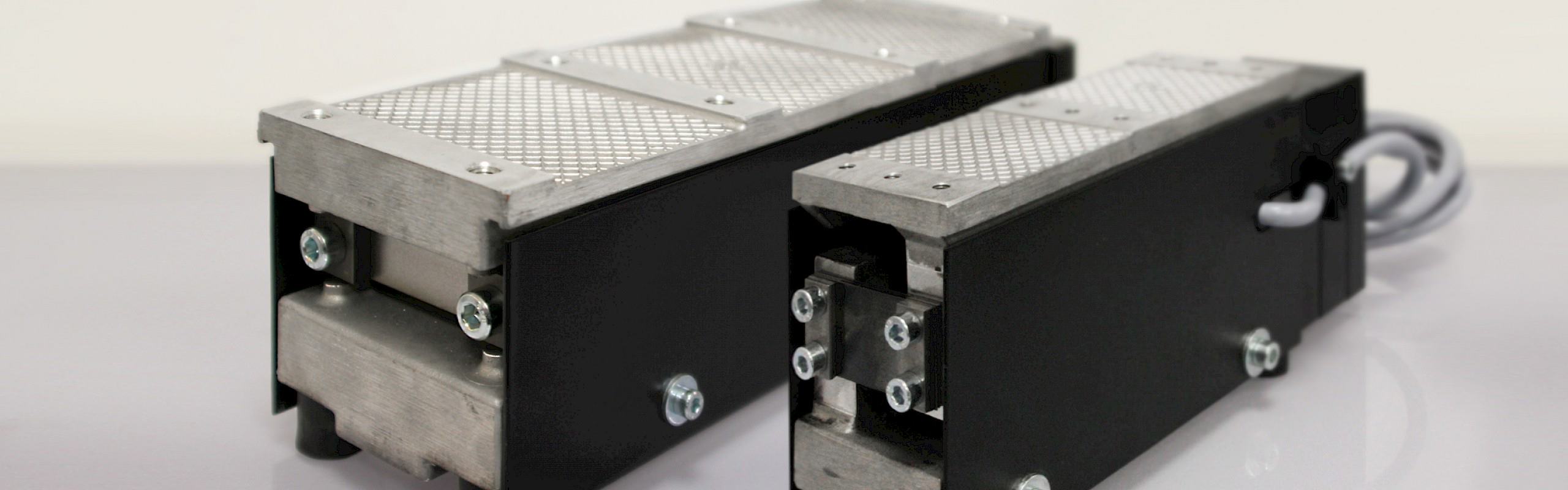

RNA bowl linear drive units are the most reliable and robust in the marketplace today, with low vibration characteristics through to the machine bed and high output efficiency.

Downloads

RNA Offer

Standard off the shelf linear feederTooling for multi-tracks

Custom solutions

The RNA range of linear feeder drive units can be supplied to suit applications from 150mm up to 3000mm long. RNA linears can carry tooling for multi-tracks are robust and simple to set and are designed to be used in conjunction with the standard range of RNA control boxes.

The FlexType multi lane linear feed system uses the RNA linear as its main source of orientation device. The linear outputs minimal vibration to the mounting frames and can therefore orientate components with very little features for selection. Due to the length and accuracy of the RNA linear tooling can be machined in straight sections with the advantage of multi tracks for component families and rapid changeover.

The RNA linear feeder compliments the RNA bowl feeder system and the most cases is utilised as the accumulation outfeed track to transfer components into your machine.

Linear

to suit your applications

SLA series

Read more

SLL & SLF series

Read more

SLC 500

Read more

GL series

Read more

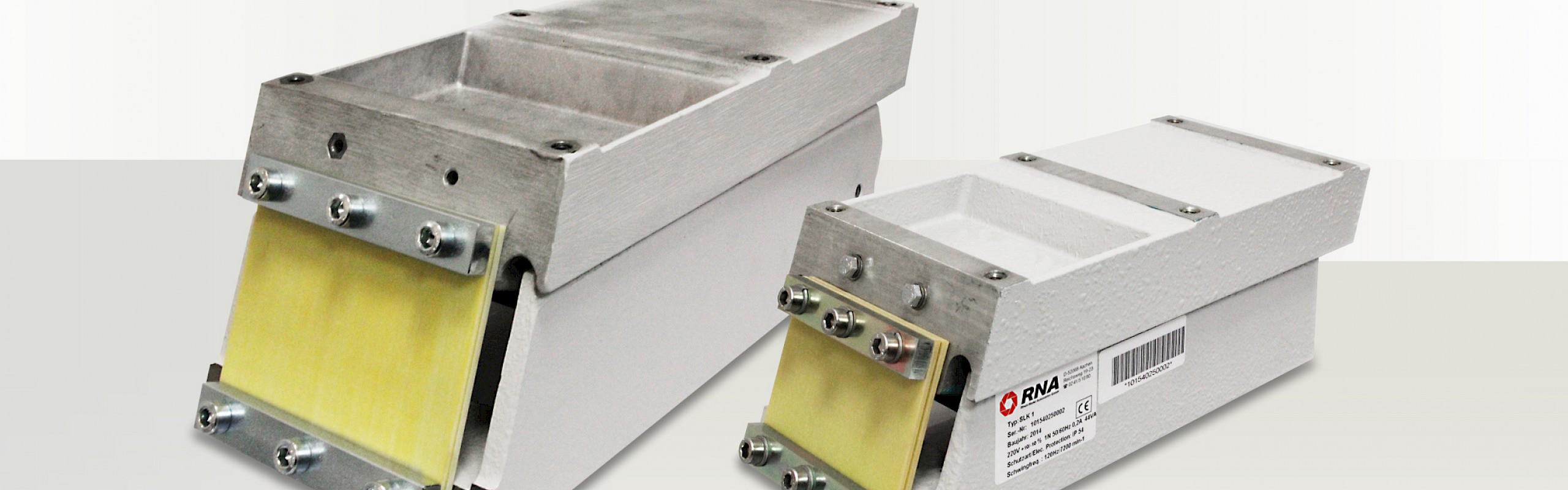

SLK series

Read moreSLS series

Read more

Accessories

Read moreContact

Send your message to a member of our team

Read our Privacy Policy to learn how we manage and protect your submitted information.