FlexCube™ Series

RNA FlexCube™ flexible vibration feeders offer high performance part feeding, pre-orientation and optimal surface distribution of bulk parts and components.

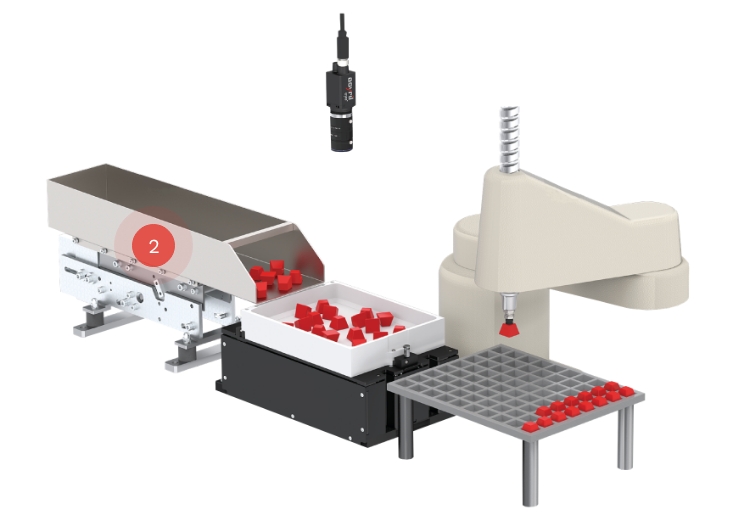

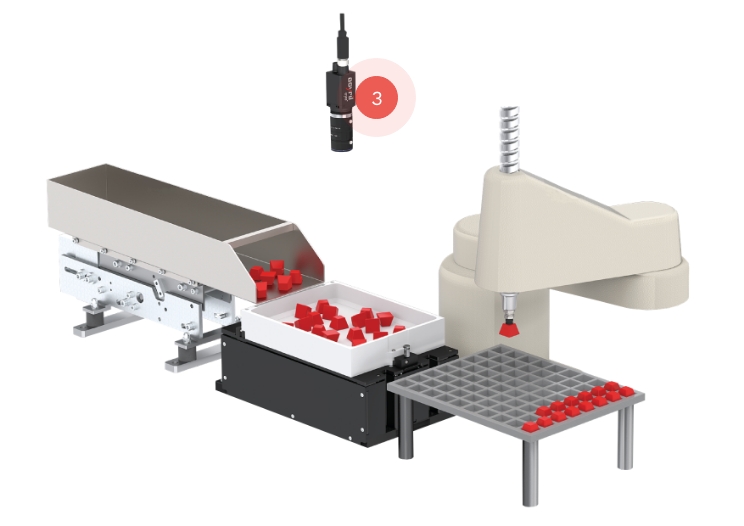

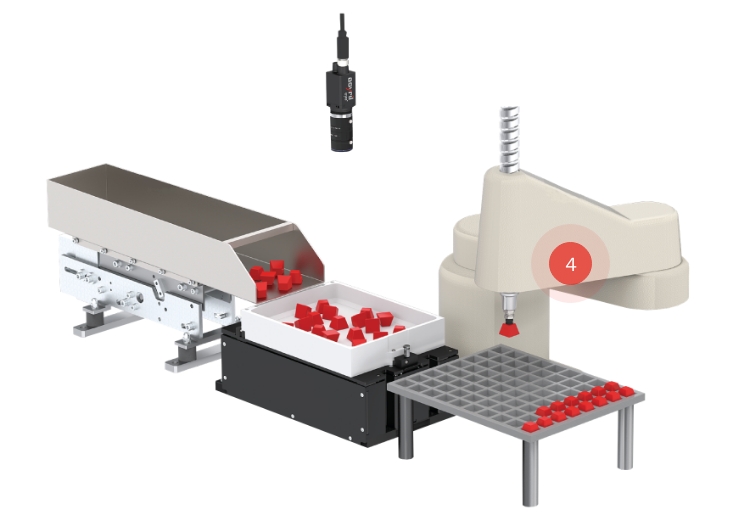

How it works

Compatible with all part geometries

99% of parts can be fed on the FlexCube™ feeders – including complex geometries and delicate materials.Minimum production changeover times

Easy exchange of part-specific vibratory plates provides for flexible and future-proof production systems.Extremely gentle part handling

Parts can be moved in all directions, including the optimal choice of flipping amplitude for each part. Minimal abrasion as parts do not need to be recirculated. Platform purge possible.Advanced reliability and durability

Advanced reliability and durability due to State-of-the-Art Voice Coil Technology ; no compressed airPrecise part detection

Precise part detection thanks to integrated, adjustable backlight / optional RNA vision inspection systemSystematic part orientation

Systematic part orientation can be achieved with intelligently structured platforms (grooves, holes, nests)Simple system integration

Simple system integration with numerous software communication plugins with the most popular robot brands.Easy configuration and installation

Easy configuration and installation through feeder control center softwareSimple Communication with all types of automation systems

Simple Communication with all types of automation systems based on standard communication protocols TCP/IP, Modbus TCP

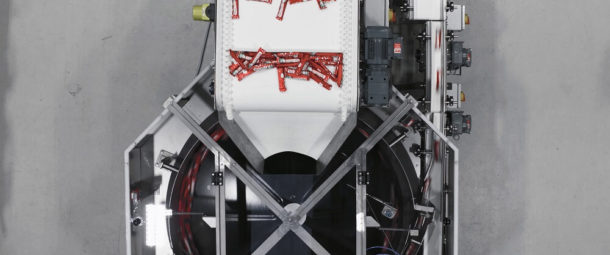

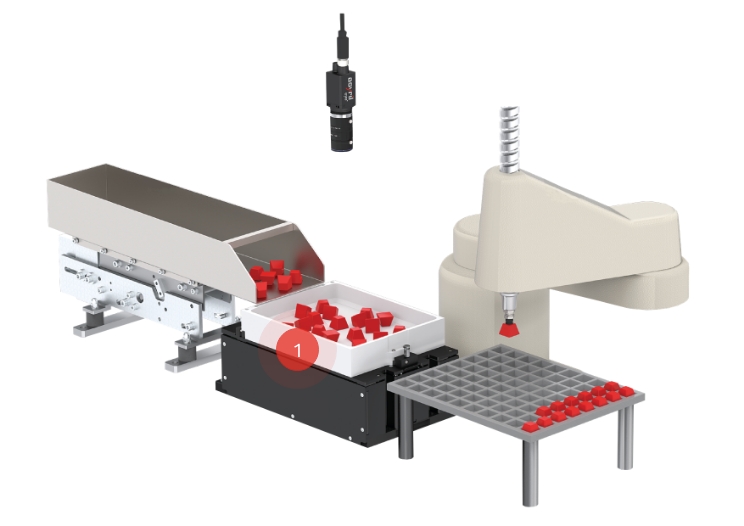

FlexType P

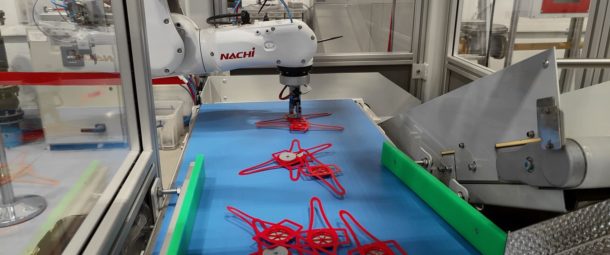

RNA has developed a new, flexible feeding system FlexType P based on our 3-axis FlexCube™ vibration platform technology.

FlexType P offers you a pre-configured feeding system adapted to your parts that is based on our FlexCube™ vibration platform with hopper, parts recirculation and camera system.

RNA also offers dual systems, as illustrated, with two platforms operating independently in parallel. Models with hopper, quick emptying system and parts recirculation for short changeover times are optionally available.

- One or two independent vibration platforms; A central robot

- Integrated hopper- and platform purge options

- Minimal production changeover times

- Easily integrated with all major brands of industrial robots

- All components are controlled using a Beckhoff PLC featuring an intuitive HMI interface.

Learn more about RNA FlexType P.

FlexCube™ Range

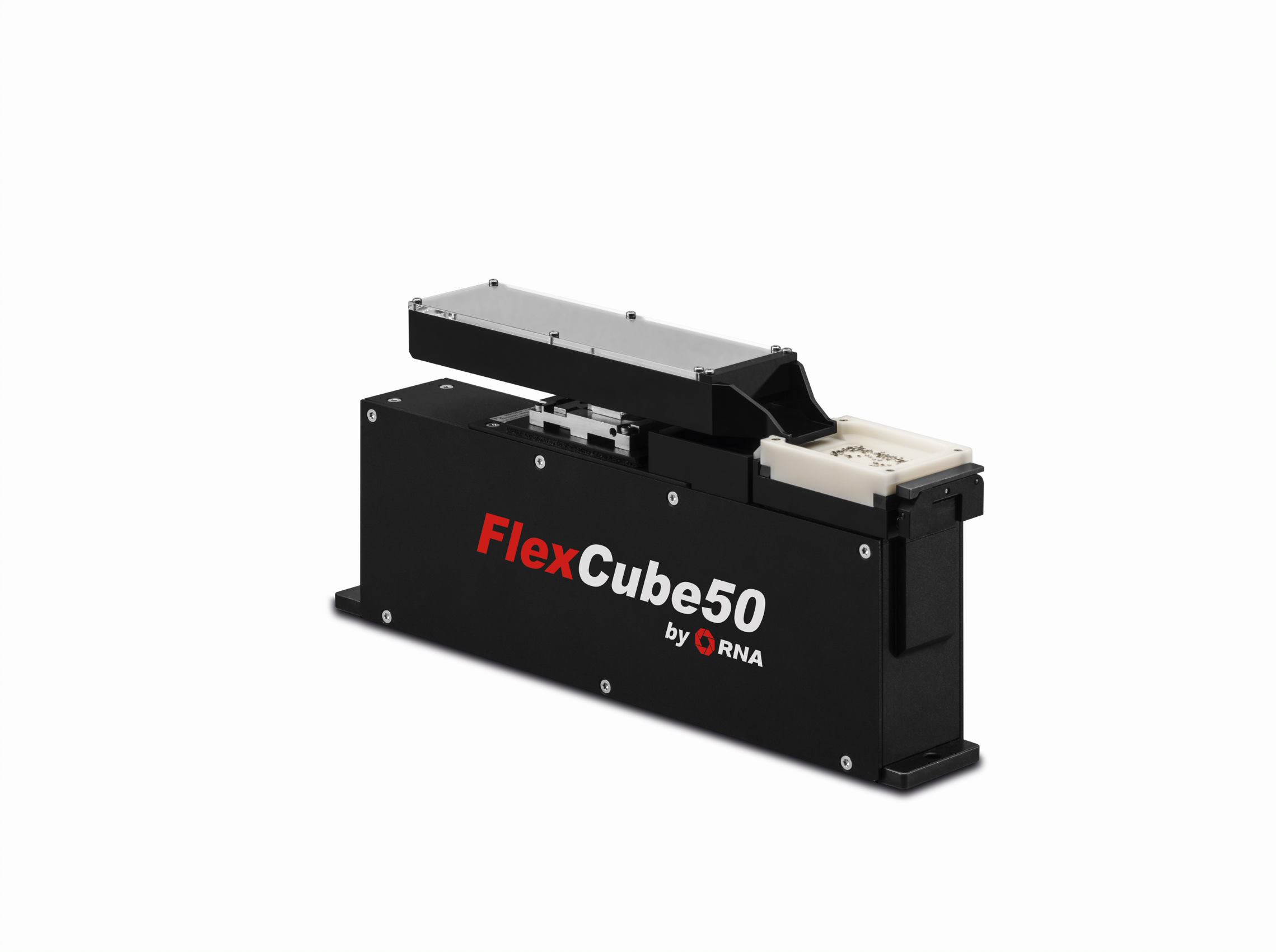

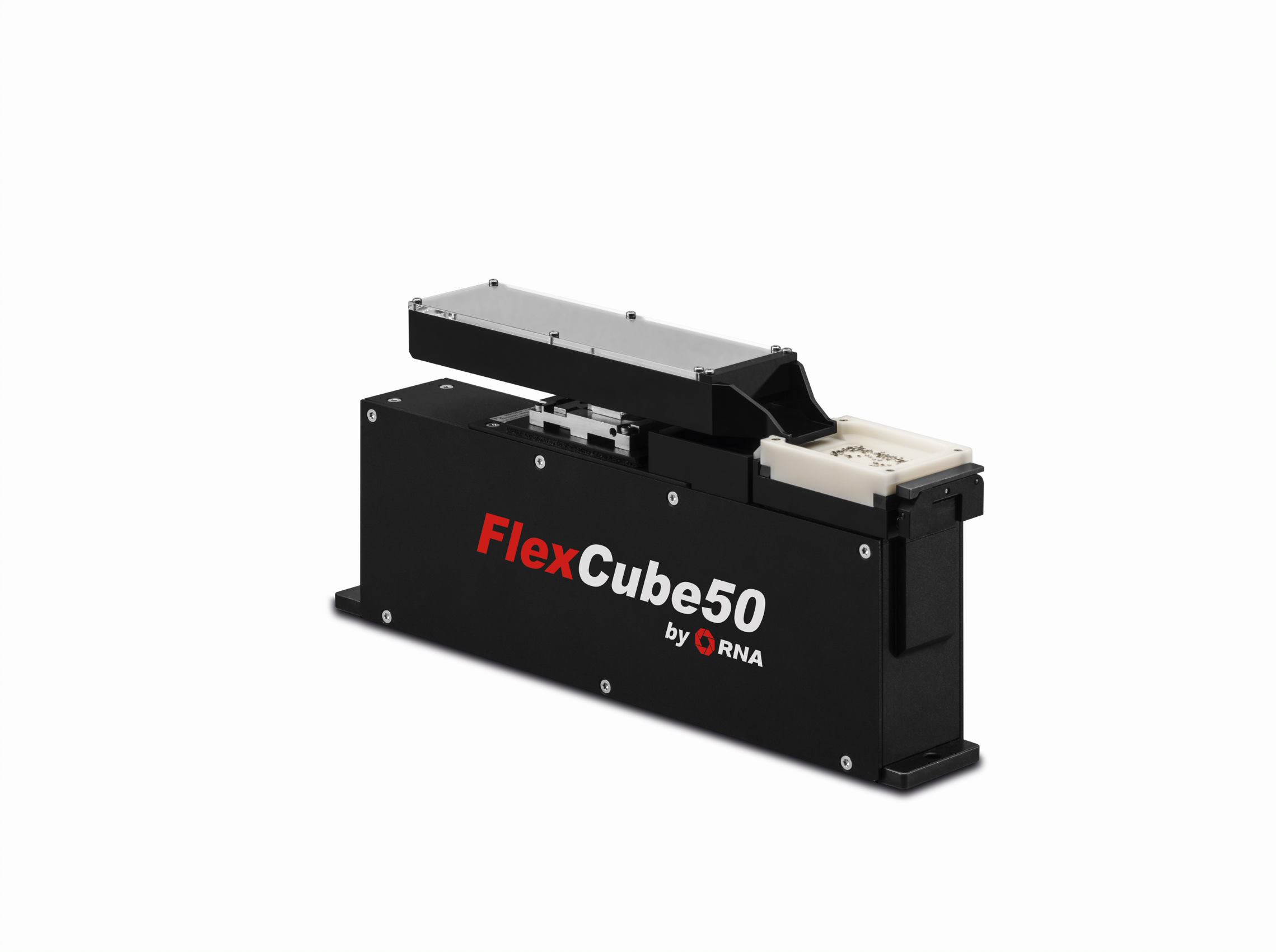

FlexCube 50

Read more

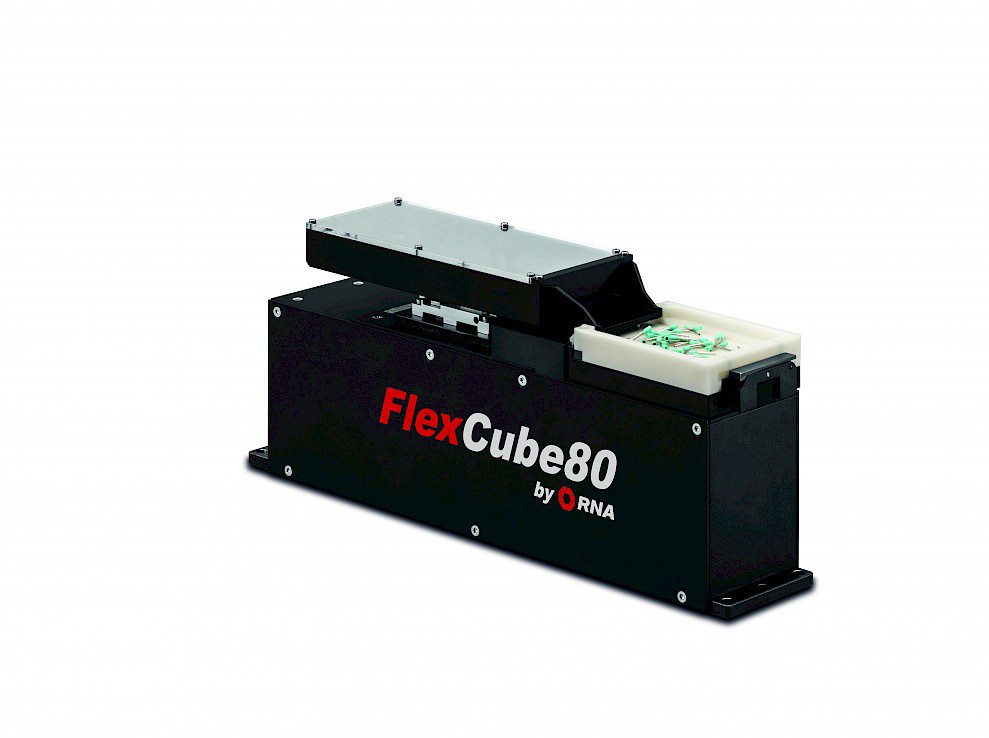

FlexCube 80

Read more

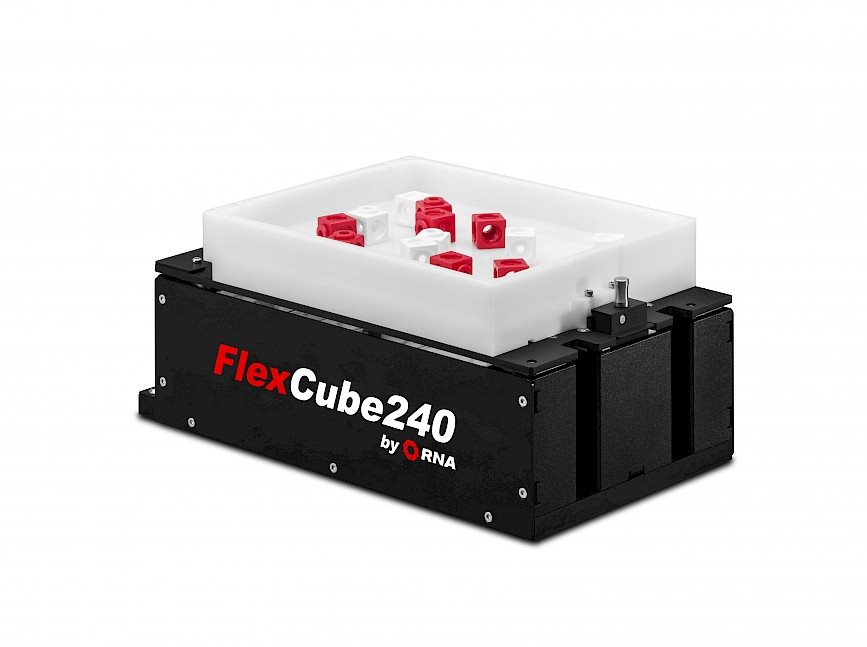

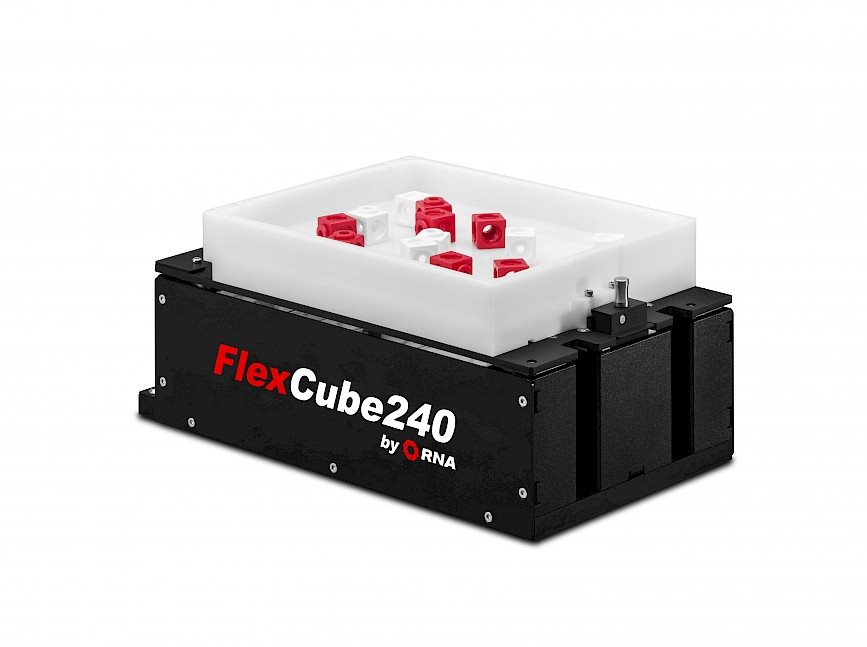

FlexCube 240

Read more

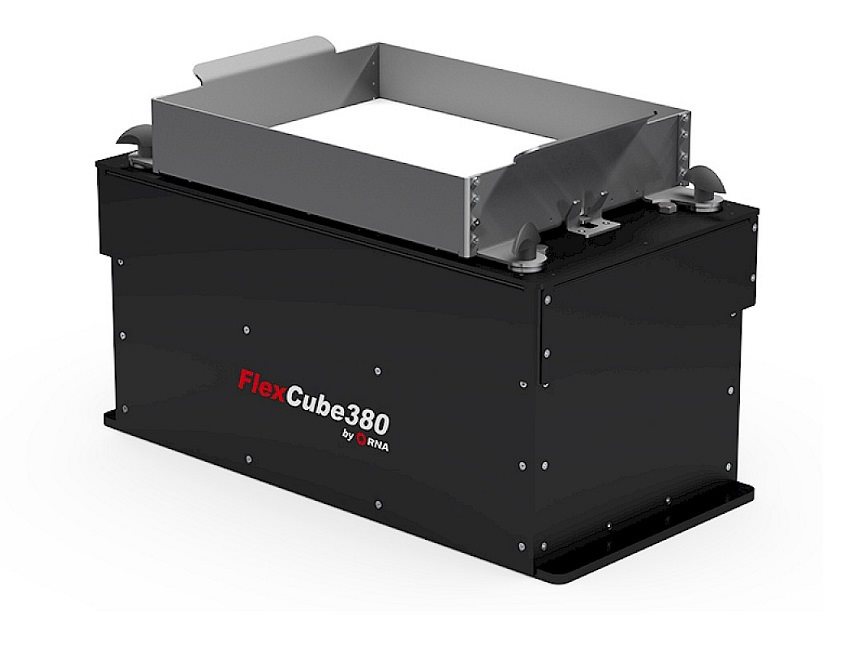

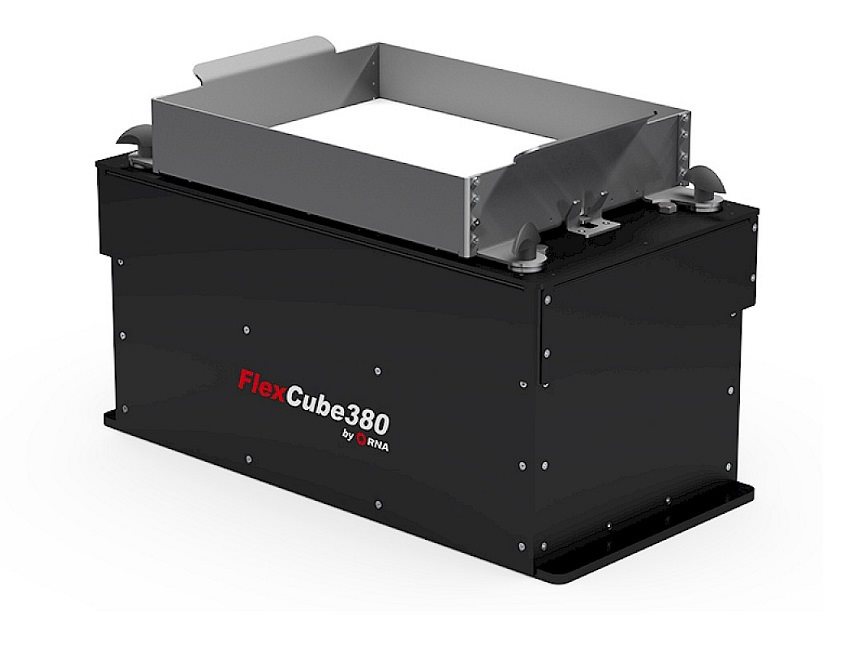

FlexCube 380

Read more

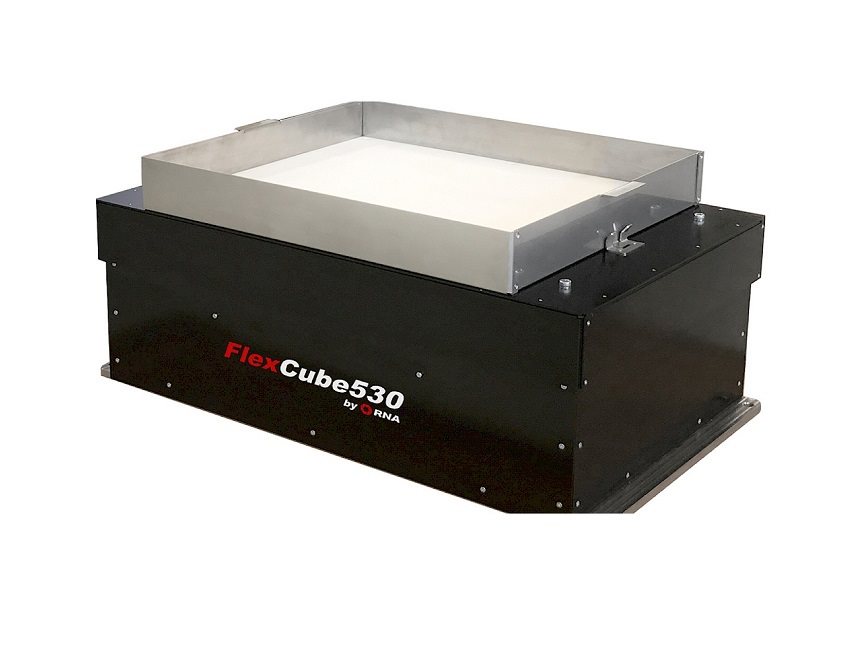

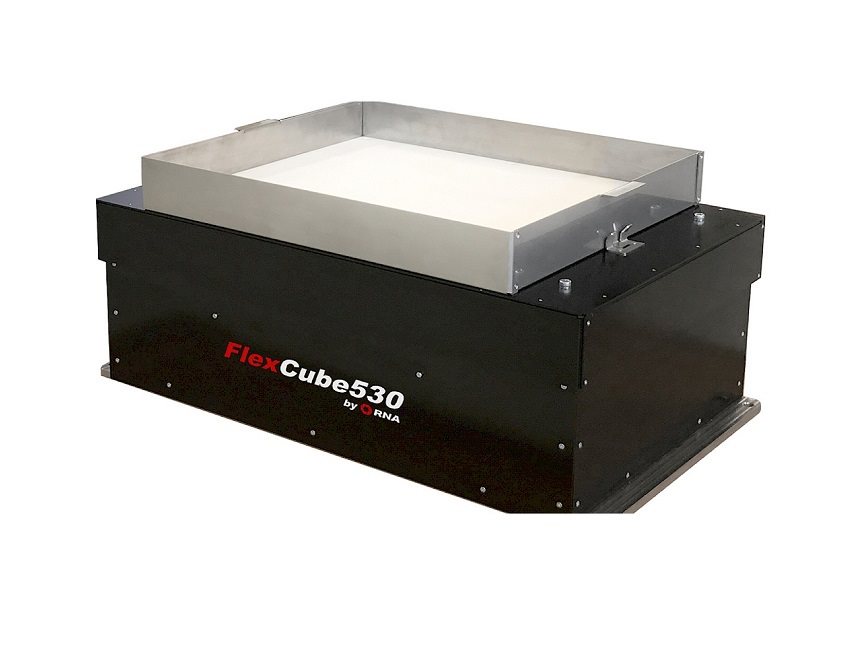

FlexCube 530

Read moreContact

Send your message to a member of our team

Read our Privacy Policy to learn how we manage and protect your submitted information.