Solution

There are nine variants in terms of moulding shape and size and all variants are produced on the same moulding machine with a moulding cycle time of between 35 to 45 seconds.

There are nine variants in terms of moulding shape and size and all variants are produced on the same moulding machine with a moulding cycle time of between 35 to 45 seconds.

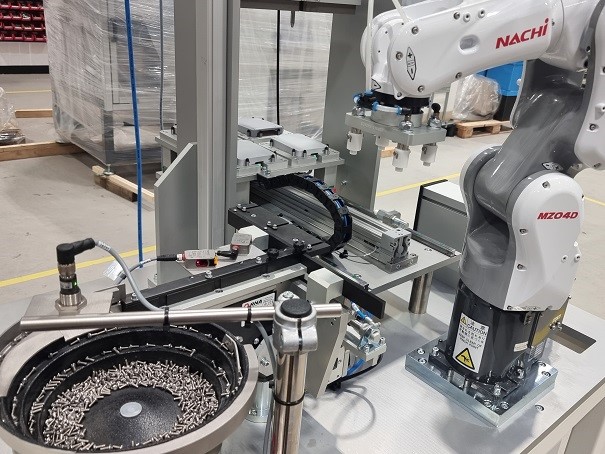

Working in close cooperation with our customer, engineers at RNA selected a six axis robot which brings increased flexibility and additional functionality to automated de-moulding. Mounted firmly to a static robot plinth beside the injection moulding machine, the robotic arm can grip all nine variants using a specially designed interchangeable tooling system.

When the moulding cycle is complete, the robot indexes to the mould tool, picks the first set of components and places them to a holding and assembly station where the letter box is automatically assembled. The robot will then pick the sub-assembly and place them vertically within its storage box.

The robot de-moulding & assembly cell replaces manual labour and allows production running costs to be reduced. The system will be set up to run overnight which leads to reduced cycle time and enhanced productivity. RNA’s flexible robotic solution has given the customer the ability to process more than one product style on one machine.