Solution

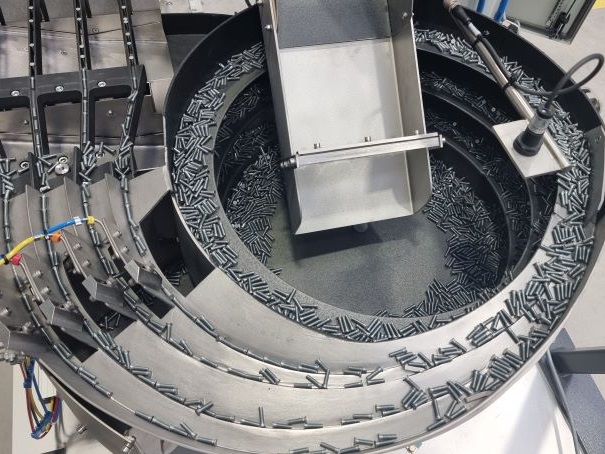

The bowl feeder system is designed to automatically sort and feed clips. The system comprises a clip bowl feeder, a linear feeder, and at the end of the feed system, an escapement to separate the component parts before they are individually fed for collection by robot.

Vibratory Bowl Feeder

A vibratory sorting bowl is tooled to feed and orientate component parts before transferring them in 1 stream to the linear out-feed.

Linear Feeder

A Vibratory linear feeder is fitted with a single lane tooled track approximately 600 mm in length, a high-level sensor to feed the stream of parts into the escapement.

Side Shuttle Escapement

Pneumatically operated escapement to separate & present 1 part for collection by robot.

Clip Bowl Feeder

Clip Bowl Feeder

Linear Feeder

Linear Feeder

Side Shuttle Escapement

Side Shuttle Escapement