Solution

The customer dimples many tubes for its shell and tube products. Each tube is dimpled individually in a press and the press is manually loaded. The purpose of this system is to automate the loading process.

A batch of tubes are loaded into a magazine which is capable of automatically adjusting to suit the length of tube being processed. One robot is used to pick parts from the tube infeed magazine then place into the press. Another robot is used to unloaded dimpled tubes from the press and also move tubes into a second position in the press where required. The press & press tool is free issued by the customer.

Infeed Magazine

Parts are manually loaded into the top of the magazine and a footswitch is used to move the fingers down the rails as parts are loaded. The end of each rail is fitted with an escapement to lift a tube ready to be picked.

Robot 1

Nachi MZ12, fitted with bespoke vacuum tool & pneumatic gripper picks tubes from magazine & place in dimpling press.

Robot 2

Nachi MZ12, fitted with 2 gripper arrangements:

- 1 gripper fitted with bespoke vacuum tool, pneumatic gripper & cylinder to push end of tube against datum. This gripper is used to pick tubes from position 1 within the tool, datum end of tube and replace into position 2.

- Other gripper fitted with bespoke vacuum tool & pneumatic gripper, is used to pick parts from position 2 within the tool and take to the unload drawers.

Unload drawers

2 unload drawers constructed in aluminium extrusion.

- Top drawer will hold a 600 X 230 x 90mm box to collect a batch of completed tubes. This drawer is fitted with a safety interlock switch.

- Bottom drawer will hold a small number of tubes for SPC. This drawer is not interlocked so tubes can be taken for checking during cycle.

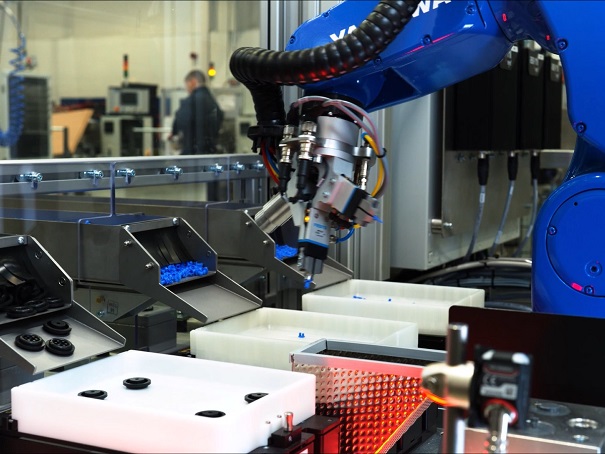

Automated Magazine Infeed

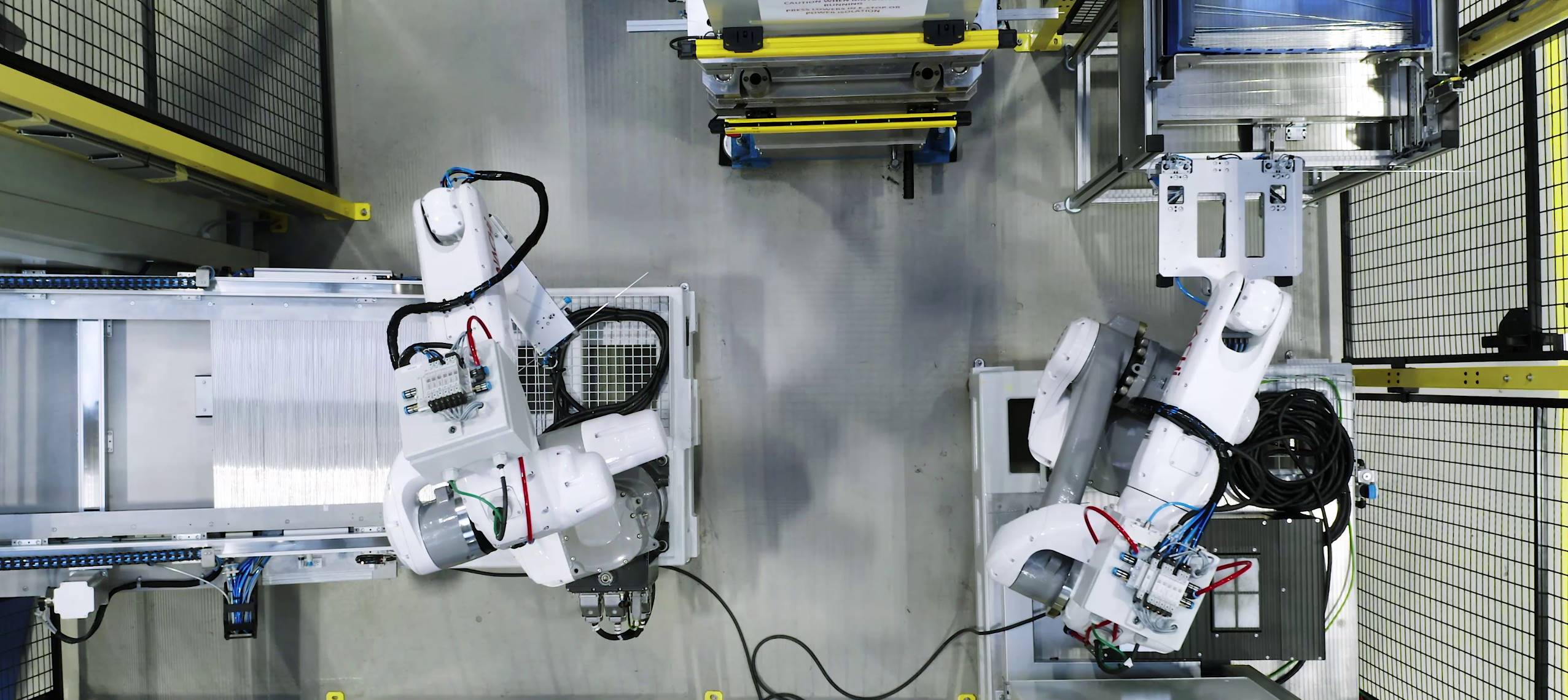

Automated Magazine Infeed Loading and Unloading Tubes in Press Machine

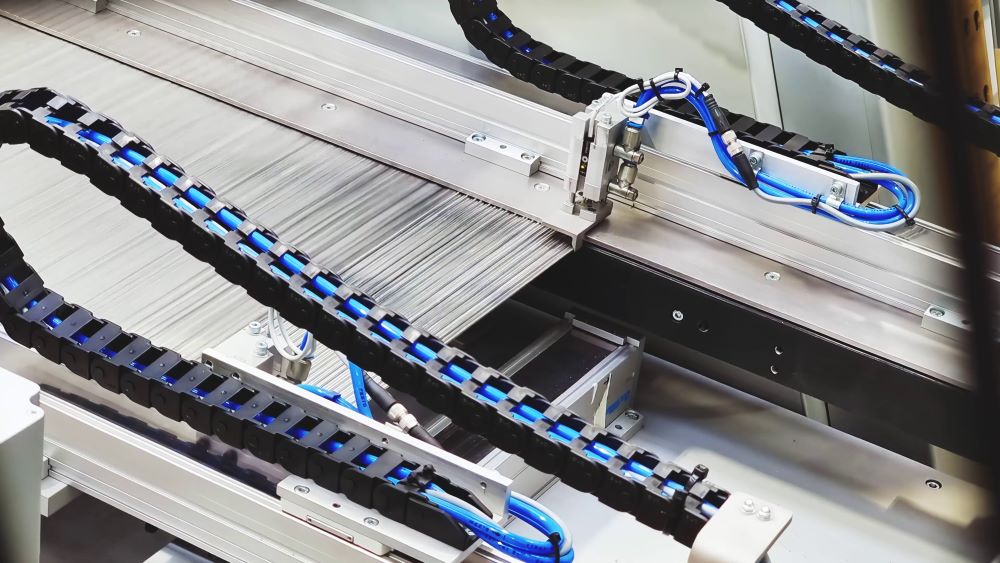

Loading and Unloading Tubes in Press Machine Robot Loading for Dimpling Process

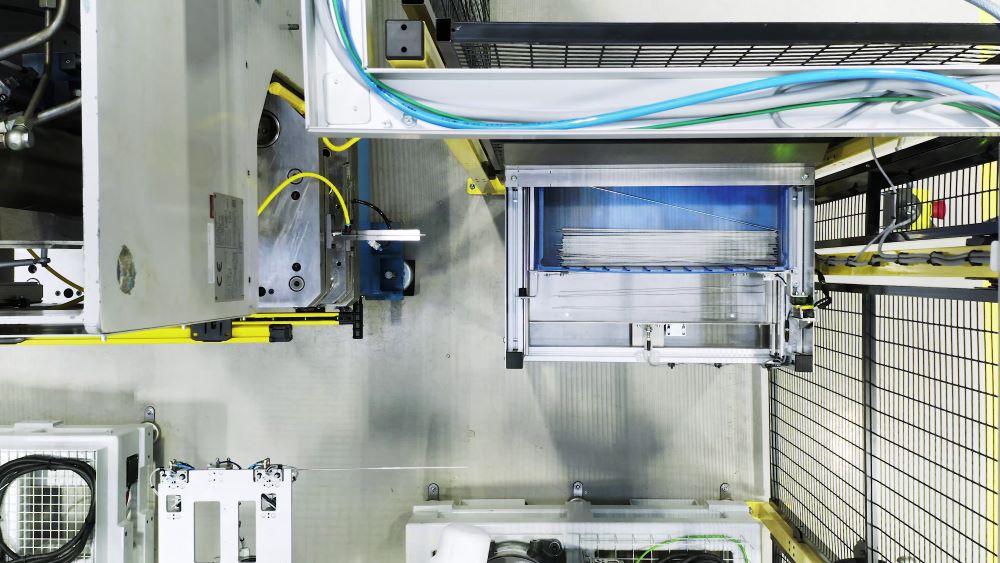

Robot Loading for Dimpling Process Unload Drawers to collect Completed Tubes

Unload Drawers to collect Completed TubesOther Case Studies

Contact

Send your message to a member of our team

Read our Privacy Policy to learn how we manage and protect your submitted information.