Product:

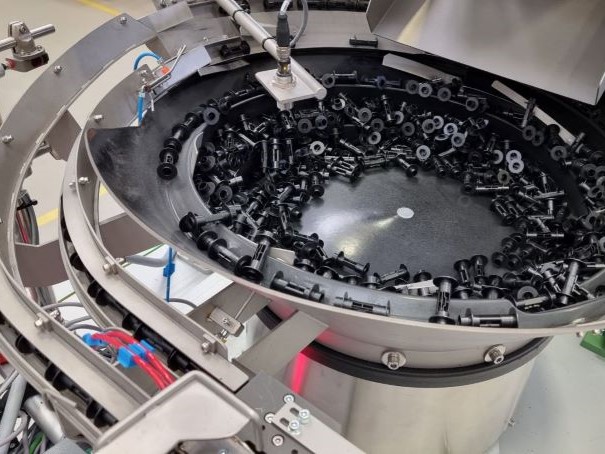

Plunger 5mm x 6mm x 6mm

Performance:

20 pcs/min

Bowl Type:

Aluminium stepped, central fixing bowl

The system consists of:

- TAG-ZA 250 bowl top with PU250 heavy duty polyurethane coating

- SRC-N 250-2 Bowl feeder drive unit

- ESK2001 twin channel digital interface variable speed controller

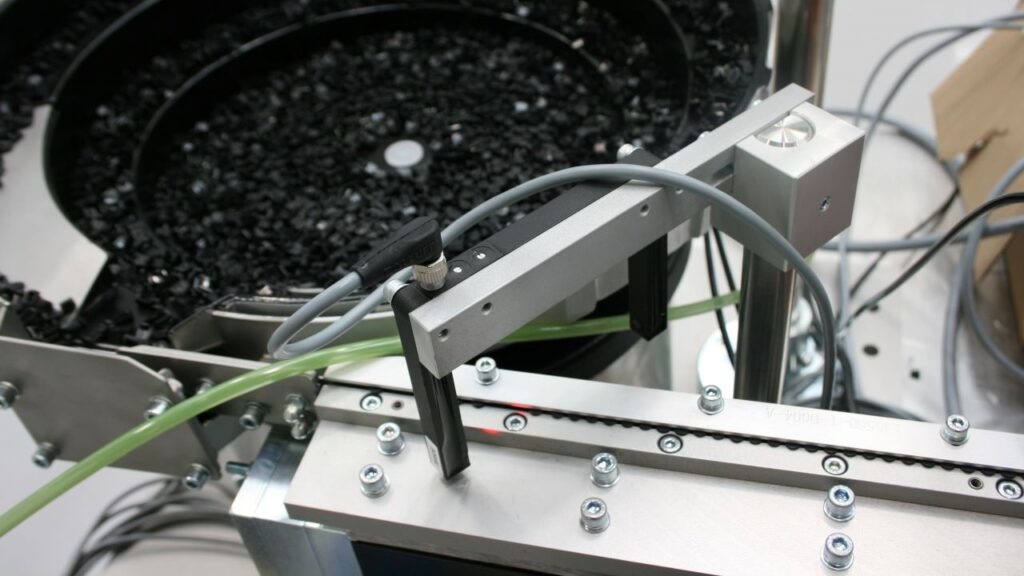

- GL01 Linear Out-feed fitted with a 350mm track

Finishes:

Component contacts: Stainless grade 304, hard anodised aluminium, and polyurethane. Non-contacts: Stainless grade 304, anodised/painted aluminium and painted mild steel.