Solution

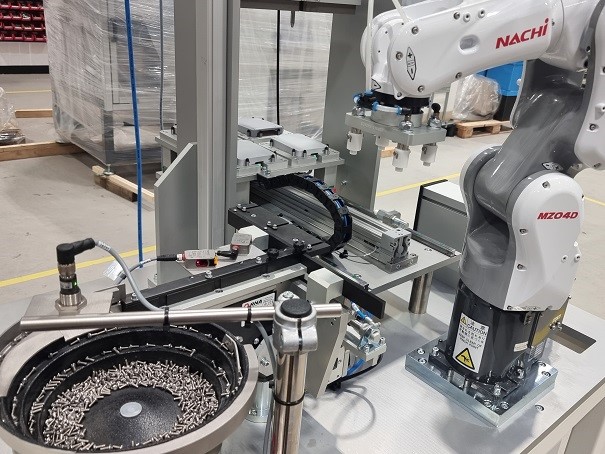

To begin the cycle, the filler caps are transferred from the pad printer out-feed conveyor and orientated and queued up ready for the robot to pick and place. The robot cell picks a filler cap when a signal is received from the end of the conveyor system saying one is ready. The robot palletises the caps in the box to a standard pattern. When the box is complete the operator removes the box and replenishes with a new box and four interleafs. The cycle then repeats.

The robotic packaging system has a two-position loading area for the box and corrugated interleaf sheets, which is an operator managed area. The operator loads the box and four interleafs onto the shuttle table and then slides the draw into the machine.

A bespoke pneumatic gripper is machined to match and profile of both the filler cap and interleaf.