Sector:

Food Industry

Product:

Cereal Bar 92-98mm long + wrapper x 16-32mm wide x 16+/-2mm high

Performance:

200 cereal bars per minute

Sequence of Operation:

Components are manually loaded onto the conveyor by an operator; the conveyor is designed to pass underneath the customer’s existing line before inclining to discharge components into a vibratory bulk hopper.

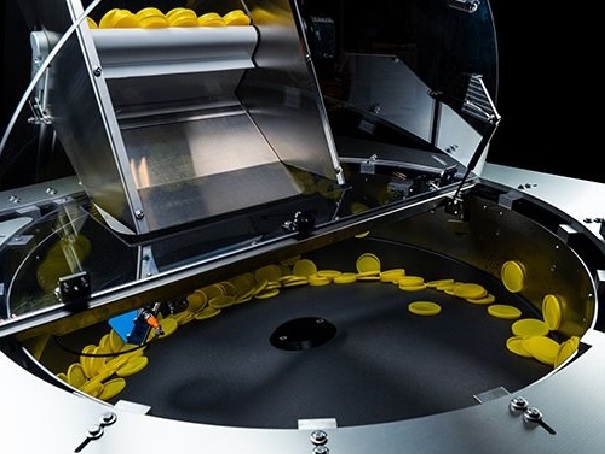

A centrifugal feeder receives components from the bulk hopper and discharges them end to end at random via a sequence of out-feed conveyors. An orientation sensor (barcode scanner) triggers a solenoid to remove miss-orientated components, returning them to the hopper; correctly orientated components are fed onto the customer’s existing line via a declined conveyor.

Finishes

Component contacts: Stainless grade 304 and FDA approved polyurethane

Non-contacts: Stainless grade 304, anodised aluminium and powder coated mild steel