Solution

The bowl feeder system is designed to automatically sort and feed tubes onto a rotary table. The system comprises a bulk hopper, a tube bowl feeder, a linear Out-feed and a pneumatically operated escapement to separate and present the component parts for collection by pick & place.

Bulk Storage Hopper

The hopper is used to store and transfer component parts into the vibratory bowl feeder.

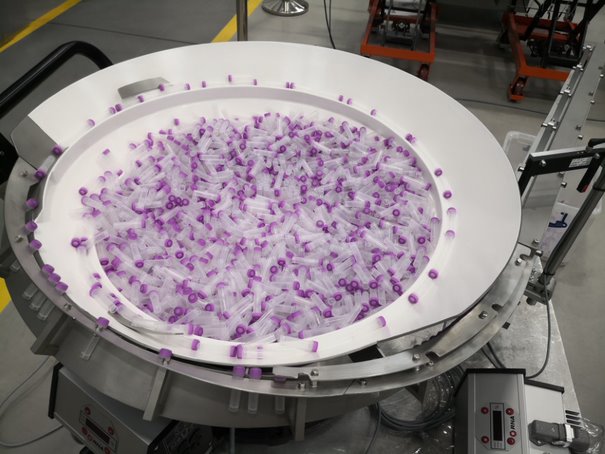

Vibratory Bowl Feeder

A vibratory sorting bowl is tooled to feed and orientate component parts before transferring them in 2 lanes to the linear out-feed; Internally lined with a white FDA approved polyurethane coating.

Linear Feeder

A Vibratory linear feeder is fitted with a twin lane tooled track approximately 600 mm in length, a high-level sensor to feed the streams of parts into the escapement.

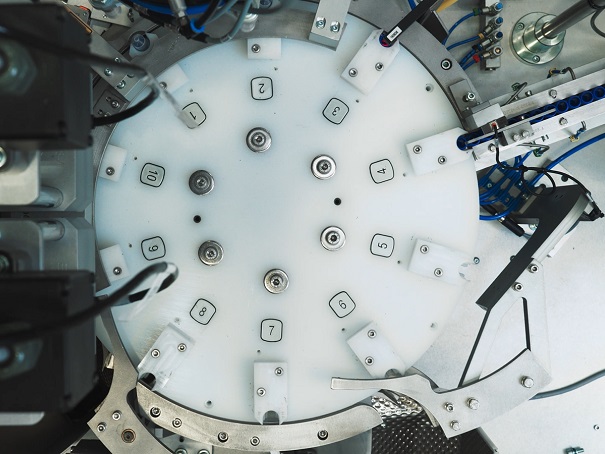

Side Shuttle Escapement

Pneumatically operated side shuttle escapement separates & presents 2 parts for collection by pick & place.

Hopper

Hopper

Vibratory Sorting Bowl

Vibratory Sorting Bowl

Linear Out-feed

Linear Out-feed