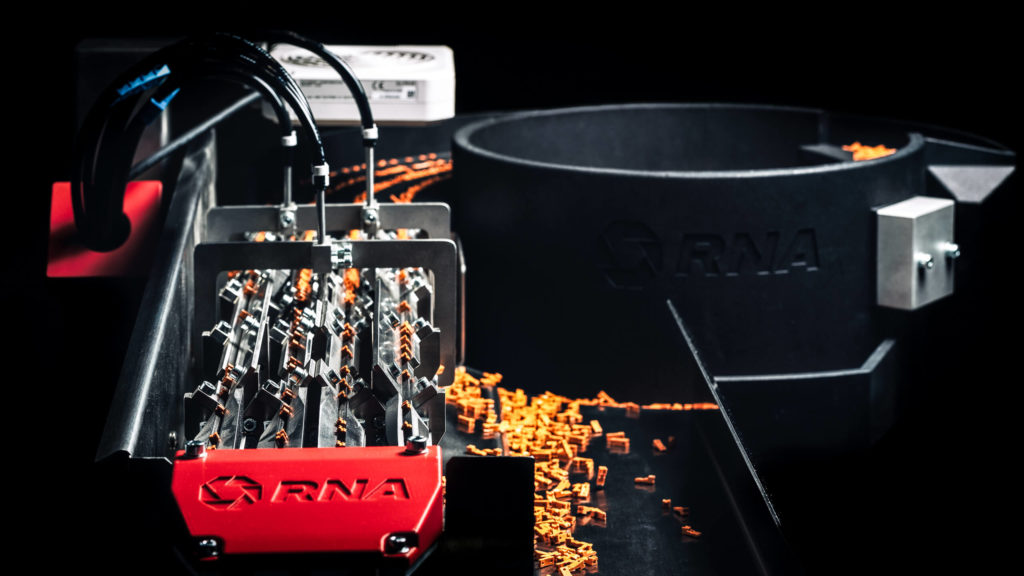

FlexType L/M/S/C

FlexType Series | Flexible high-performance multi-lane linear system by RNA

Features

- Feeding rate of 2500 parts/min- Changeover time < 1 min

- Available in size L, M, S and C

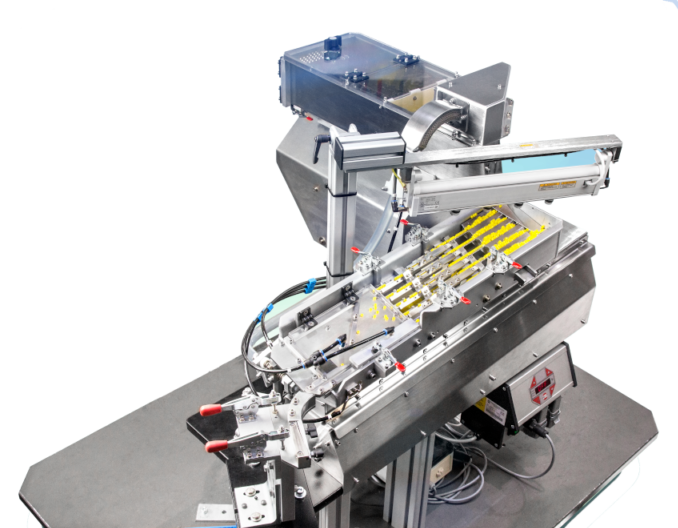

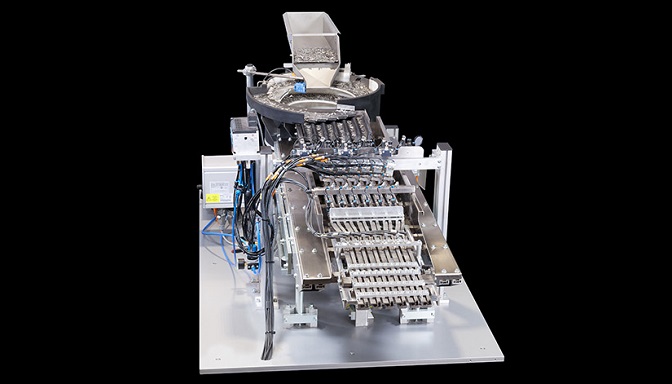

The Multi-lane Linear System of the FlexType series from RNA are characterized by their high performance and ease of use. Depending on the target application, the FlexType Multi-lane Linear Systems are available in three different sizes (L, M, S and C). The FlexType C (compact) is designed to be particularly space-saving with high availability.

The multi-lane system design allows a high feeding rate of up to 2,500 parts per minute. In contrast to centrifugal feeders, which have similar performance rates, FlexType Multi-lane Linear Systems by RNA can also process asymmetrical parts. RNA has a high number of applications from a wide range of industries with high production volumes.

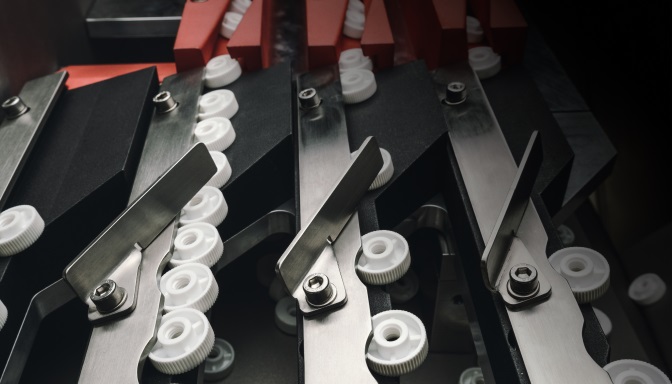

The core feature of the FlexType Multi-lane Linear Systems is the patented linear drive technology of RNA, which has a unique feature due to its vibration behaviour and performance. Thanks to the vibration behaviour, the systems are also suitable for component parts with small features. The sorting can be built as a basin or compact catamaran system.

Component parts:

- low noise emissions

- very low use of air

- suitable for parts with smallest sorting features

- easy changeover

- main unit applicable for changing range of component parts

Machine operations:

- open system with good accessibility

- very fast emptying of system (only 2 minutes)

- easy and fast changeover in case of component parts change

Machine performance:

- high availability

- low vulnerability to failures

- fast circulation of component parts

- immediate sorting after filling – even at small batch sizes

- high performance

High Performance Linear Feeding Systems

FlexType L

Read more

FlexType M

Read more

FlexType S

Read more

FlexType C

Read moreContact

Send your message to a member of our team

Read our Privacy Policy to learn how we manage and protect your submitted information.