Customised Solutions

Specialises in developing customised solutions that perfectly fit the unique requirements of each client, ensuring optimal performance and integration with existing processes.Comprehensive Support Services

Provides extensive after-sales support, including training, maintenance, and technical assistance, to ensure smooth operation and quick resolution of any issues.Long-Term Partnership and Consultation

Acts as a long-term partner for clients, offering ongoing consultation and upgrades to keep pace with technological advancements and changing industry demands.Your products

Passive Components

Active Components

Connectors and Terminals

Fasteners and Hardware

Electromechanical Components

PCB

Specialty Electronic Components

RNA’s Capabilities

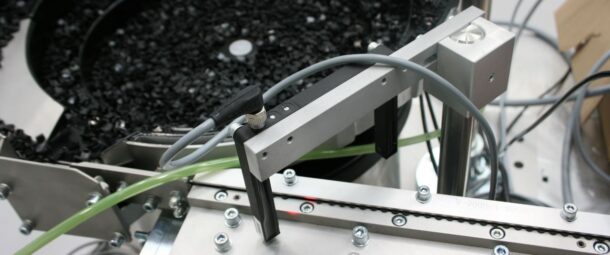

Incorporates vibratory bowl feeders, centrifugal feeders, and flexible feeder systems to sort and feed components like capacitors, connectors, screws, and chips with precision for assembly line integration.

- Vibratory bowl feeders, centrifugal feeders and step feeders for capacitors, connectors, and screws.

- Flexible Feeders FlexType™ P and FlexType™ R for flexible component handling, enabling quick changeovers.

- Applications: Feeding pins for connector assembly or capacitors for PCB production.

Combines robotic pick-and-place and high-speed packaging robots for tasks such as placing components on PCBs, soldering, or packing finished electronics, with collaborative robots (cobots) for flexible, safe operation.

- Robotic pick-and-place systems for accurate component placement on PCBs.

- High-speed robots for rapid packing and assembly.

- Collaborative Robots (Cobots): Integrate 6-axis cobots for safe, flexible automation alongside human operators.

- Robotic Handling: Automate part transfer, palletising, and machine tending.

- Custom robotic cells for tasks like soldering or connector assembly.

Automates the assembly of electronic components, such as connectors, enclosures, or circuit board subassemblies, ensuring high precision and repeatability.

- Rotary Indexing Machines perform multiple tasks (e.g., soldering, inspection, and assembly) in a single cycle, optimising throughput for high-volume electronics production.

- PCB Assembly: Automated systems for the precise placement of components on printed circuit boards, including solder paste application, component placement, and soldering processes.

Includes filling and sealing systems for protective packaging, dispensing systems for coatings or potting compounds, labelling and coding systems for barcodes and serial numbers, and automated assembly for packaging components like enclosures, plus palletising and depalletising for efficient stacking of packaged electronics.

Systems designed to conduct electrical and functional tests on electronic components and finished products, including automated optical inspection (AOI) for defect detection on PCBs.

Systems equipped with advanced sensing and imaging technologies for dimensional measurements, surface inspection, and quality control of electronic components.

RNA’s in-house engineering team designs custom systems to meet unique client requirements in the electronics sector.

- Custom Machinery Design: Develops specialized equipment for handling and assembling electronic components.

- Mechanical and Electrical Engineering: Creates robust, reliable systems with precise control.

- Testing ensures compatibility with production requirements.

Custom and standard systems for scalability and quick deployment.

- Standard flexible Feeder system for electronic component assembly (E.g., FlexType™ P Assembly)

- Standard flexible Feeder system for electronic component packaging (E.g., FlexType™ P Pack)

- Standard flexible Feeder and vision module for electronic component pick an place (E.g., FlexType™ R)

- Standardised vibratory bowl feeder reduces development time (E.g., EcoType™).

Utilising advanced AI and simulation tools (RNA Digital), RNA optimises system designs for performance, reliability, and efficiency, predicting part handling outcomes and reducing development time for OEM applications.

Trusted by

Applications

Experts say

Electronics Automation FAQs

Automation in the electronics industry refers to the use of control systems, such as computers or robots, and information technologies to handle different processes and machinery in the production and manufacturing of electronic components and devices. This can include tasks like assembling circuit boards, testing electronic components, and packaging finished products.

Automation in the electronics industry is employed in various ways, including:

- Assembly Lines

- Quality Control

- Testing

- Material Handling

- Packaging

- Inventory Management

RNA designs systems to handle a wide range of components used in electronics manufacturing, including capacitors, resistors, housings, terminals, PCB connectors, switches, LEDs, sensors, and small plastic or metal casings. We specialise in feeding and orienting miniature and delicate components with tight tolerances.

Our systems are engineered for precision feeding and positioning. Custom tooling, anti-static materials, and gentle handling mechanisms are used to prevent damage to sensitive parts and ensure reliable downstream assembly.

For varied or high-mix production, RNA offers flexible feeding systems like FlexCube™ and FlexType™ P, which enable quick reconfiguration and tool-less part changeovers. These are ideal for electronics manufacturers producing multiple board designs or product variants.

Yes. RNA integrates vision inspection systems to verify orientation, part presence, code marking, and dimensional compliance.

Get in touch with out team today to discuss your requirements on 0121 749 2566 or email [email protected].

RNA will be able to help you to feed small electronic parts due to our experience within the industry, we have the skillsets and knowledge to assist you with any improvements and requirements you have.

Adam Hallifax | Sales Engineer