Our Proven Process with RNA Digital Solution

We define all key requirements to ensure the feeding solution is designed around the part, the process, and the operating environment from the very beginning.

• Part CAD & requirements

• Orientation & output

• Constraints & environment

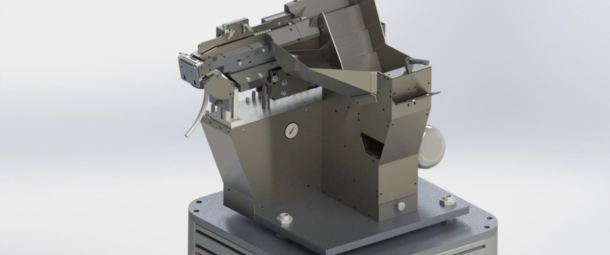

• Feeder type selection

Using RNA AI & simulation tool Digital Feeder™, we digitally assess the component’s characteristics and feeding concept to confirm feasibility and reduce risk before physical manufacturing begins.

• Sorting concept

• System-level simulation

• Feasibility validation

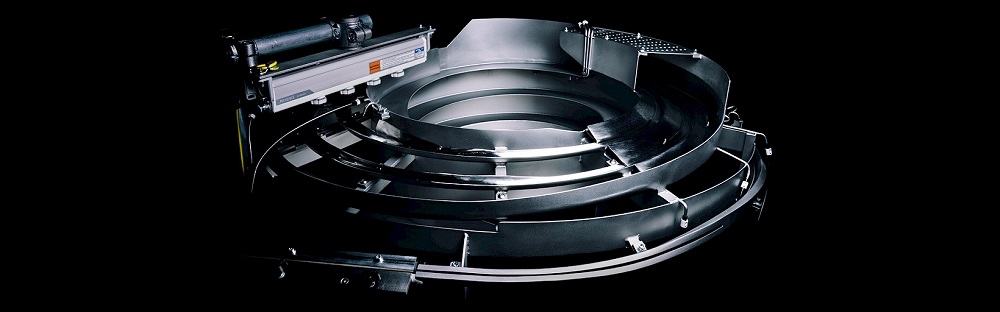

The validated digital concept is converted into a detailed mechanical design, with all geometries and layouts finalised for manufacture.

• Final bowl & track design

• Tooling definition

• Layout finalised

Track and tooling geometry are digitally validated to ensure the mechanical design supports stable and reliable feeding behaviour.

• Track & tooling geometry

• Validation & Commissioning

• Feed rate validation

The simulation tool Digital Motion™ is used to simulate and optimise drive behaviour, ensuring predictable vibration characteristics before commissioning.

• Drive & vibration simulation

• Spring & frequency tuning

• Optimise running parameters

The system is built using CNC or 3D-printing for exact replication of the digital design. This results in predictable behaviour and minimal on-site tuning.

• CNC or 3D-print the bowl selection & tooling

• Physical system build

• Reduced on-site tuning

• Predictable behaviour

Digital data supports long-term operation, enabling system replication, efficient servicing, and future modifications.

• Reproducible systems

• Service & relining

• Change tooling

• Digital documentation reuse

RNA provide automatic parts handling equipment for high volume production in automotive, cosmetics, pharmaceuticals, electronics, food, plastics and metal working industries – anywhere, where there is a need to automate the handling and orientation of component parts.