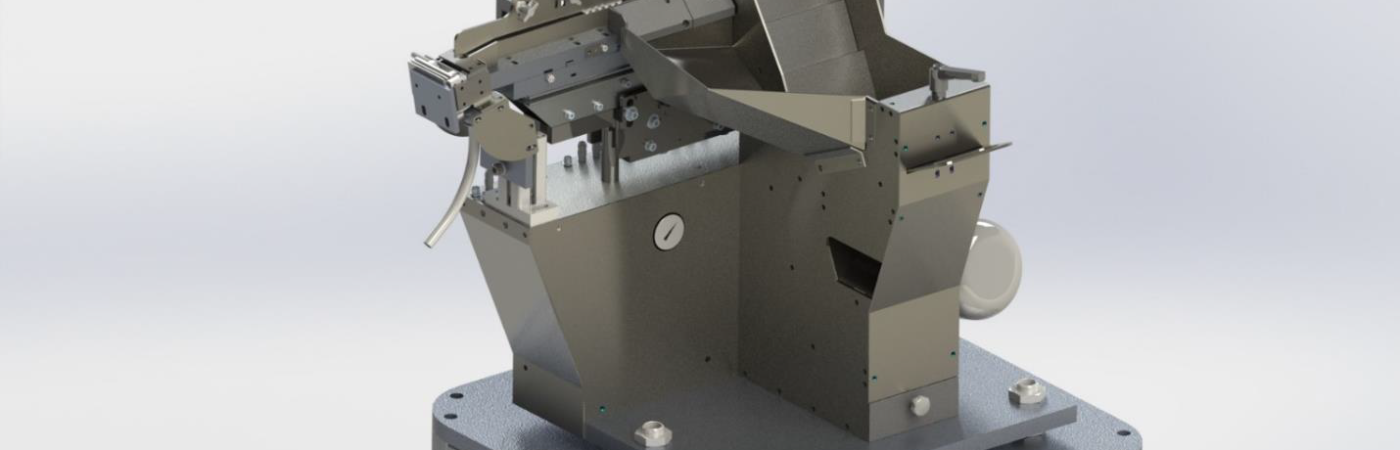

Step Feeders

RNA Step Feeders are engineered to be robust and reliable, making them ideal for handling bulky or heavy components. They are capable of feeding and orienting products even when oil, debris, or other harsh materials are present on the surface, ensuring consistent performance in demanding environments.

Downloads

RNA Offer

Standard feedersCustom, customer-specific solutions

Suitable for Industrial, Pharmaceuticals, Medicals

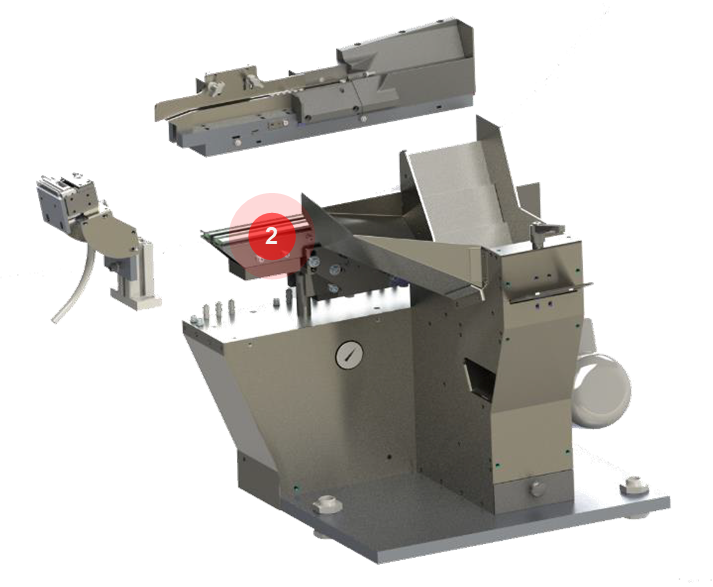

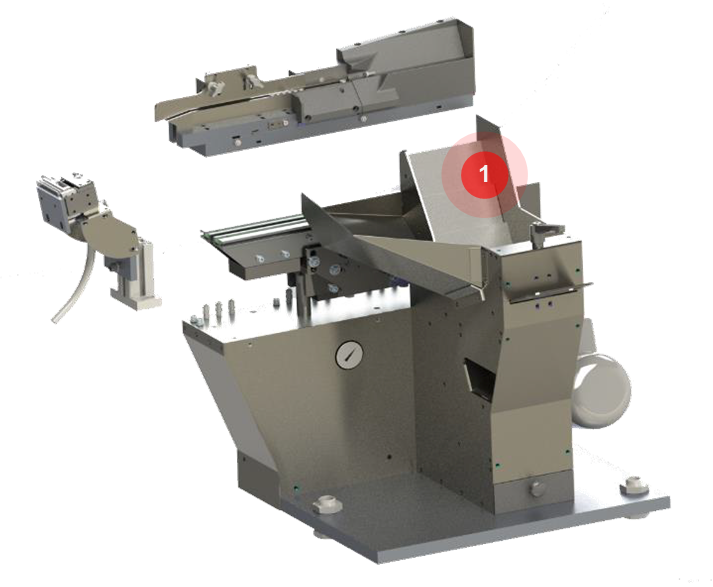

The RNA step feeder is manufactured in such a way that the static hopper, which has a very low filling height, can be loaded manually. The components are collected from the hopper by elevating plates, pre-sorted and fed to the top without any further feeding technique until they reach the desired transfer height.

Key features of the RNA step feeder are that it operates quietly and without vibration.

Our experienced staff are available to provide advice and offer this system to you which can be adapted and integrated with multi-lane tracks to meet your requirements.

Standard Step Feeder hopper sizes range from 10 to 60 litres capacity and on request can be made to suit your individual requirements.

Low noise

Operates quietly and without vibrationLow maintenance

Low maintenance and upkeep requiredMetered feeding

Automatic metering of parts into the step feeder bin increases bulk part storage capacityGentle vibration free feeding

Minimal damage to parts being handled due to no vibrationLow load height

Low filling height that can be loaded manuallyFast changeover

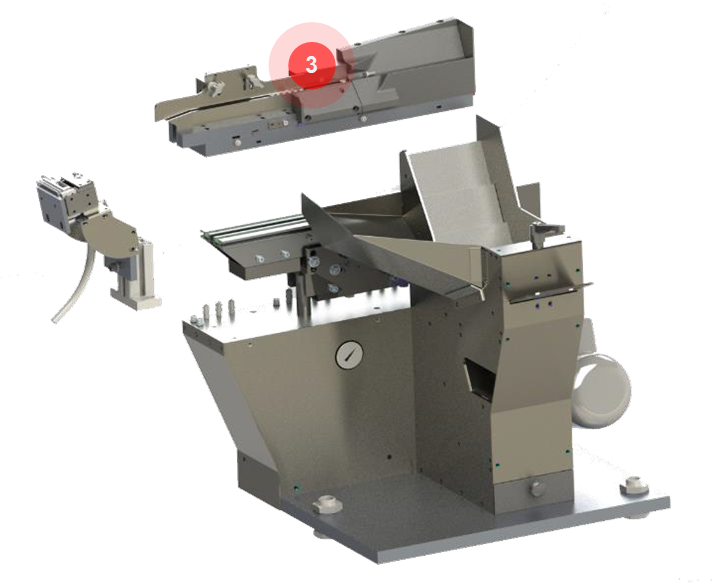

Fast changeover for different formats by means of quick-change elements for the orienting and accumulating rail ensures flexibility and a cost-effective investmentWhat is a step feeder?

Step feeders operate by raising a series of steps that create an upward waterfall effect. The component parts are transported into the rail of the singling mechanism via these steps. Vibration is used only near the rail to position the parts correctly for automatic feeding. The gentle part handling and low-friction feeding ensure minimal damage to the components, making step feeders especially suitable for industries that handle delicate products or require gentle processing.

RNA Standard Range RNA provide standard and custom feeding systems.

Downloads

Contact

Send your message to a member of our team

Read our Privacy Policy to learn how we manage and protect your submitted information.