Bowl Feeders

Vibratory Bowl Feeders are among the most sophisticated, reliable, and robust feeding units available on the market today. RNA bowl feeders carefully feed and orient your products while ensuring a consistent and accurate flow of components into your production machinery.

Downloads

RNA OFFER

» Standard feeders» Digital feeders

» Custom system design

» Customer-specific solutions

Suitable for Industrial, Pharmaceuticals, Medicals

Our unique patented multi-magnet drive units ensure smooth, consistent feed characteristics with minimal vibration transmitted to the assembly machine. All drive units and associated control boxes are CE marked and, where required, UL/CSA approved for the North American market.

RNA bowls can be manufactured from a variety of materials, including stainless steel, aluminum, and polyamide, with optional coatings such as polyurethane, Habasit, brush, flock, or Metaline—each selected to best suit the specific application.

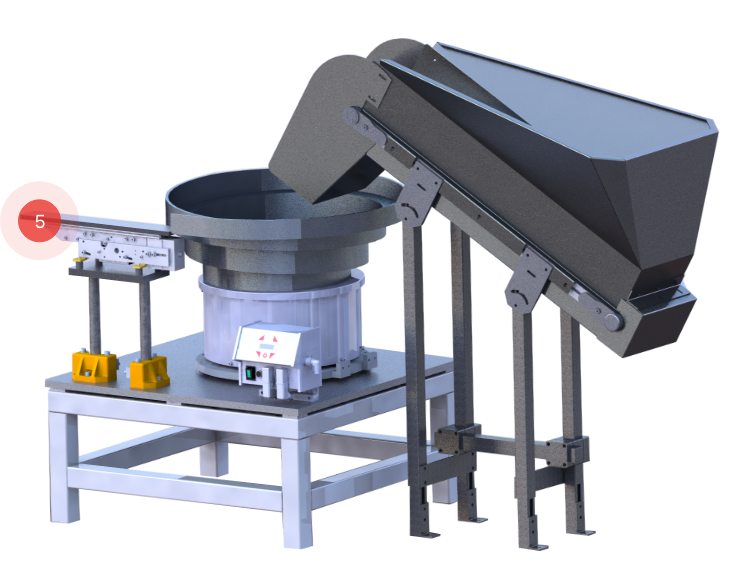

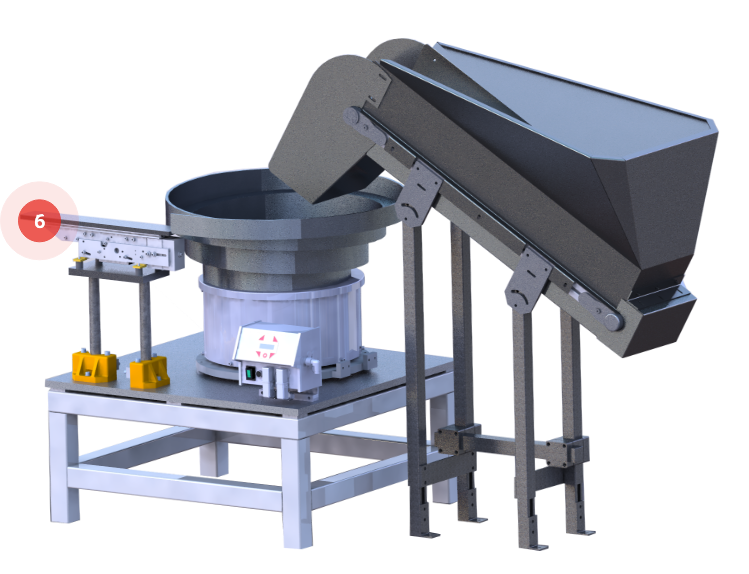

Available in sizes ranging from 69 mm to 1,200 mm in diameter, RNA offers a complete range of vibratory bowl feeders available from stock, including drive units, bowls, bowl centers, control boxes, and accessories such as stands, base plates, sound enclosures, and sensors. Custom configurations are available upon request.

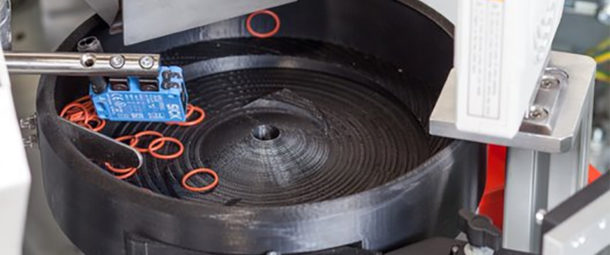

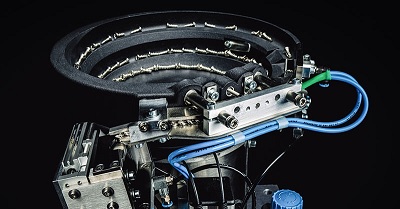

We also design and manufacture tooling for component orientation, which—combined with our standard equipment—provides fully integrated systems ready for use in process machinery, packaging lines, and assembly operations.

Low noise

Operates quietly with minimal transmitted vibration thanks to the advanced multi-magnet systemDurable

Exceptional durability with smooth feed characteristics and simple servicing requirementsFeed complex parts

Versatile design suitable for nearly all component types, including complex-shaped partsHigh output

Multi-lane part feeding enables higher output rates to meet increased production demandsCost effective

A cost-effective alternative to manual labor, reducing both time and labor costs for manufacturersEasy retooling

Easily retooled to accommodate changes in product design, style, or sizeWhat is a vibratory bowl feeder?

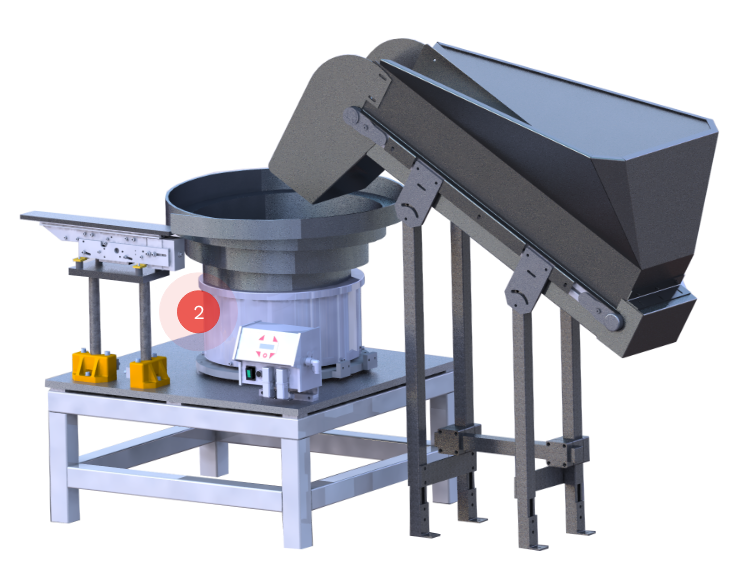

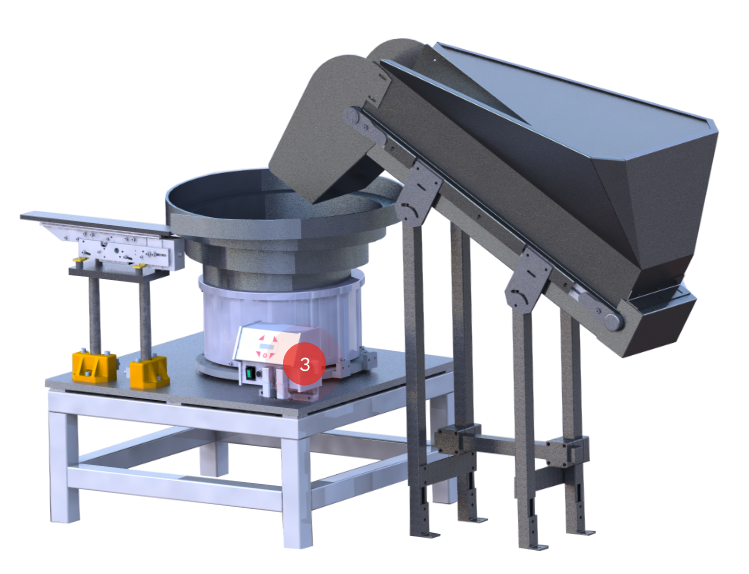

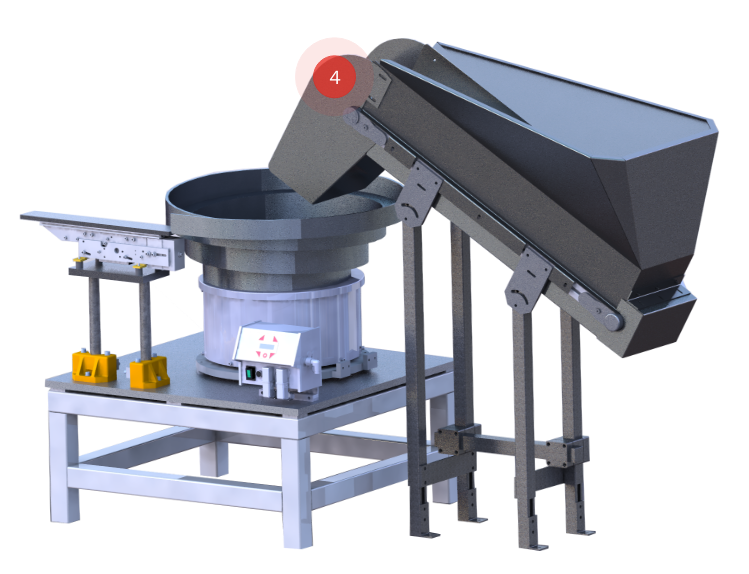

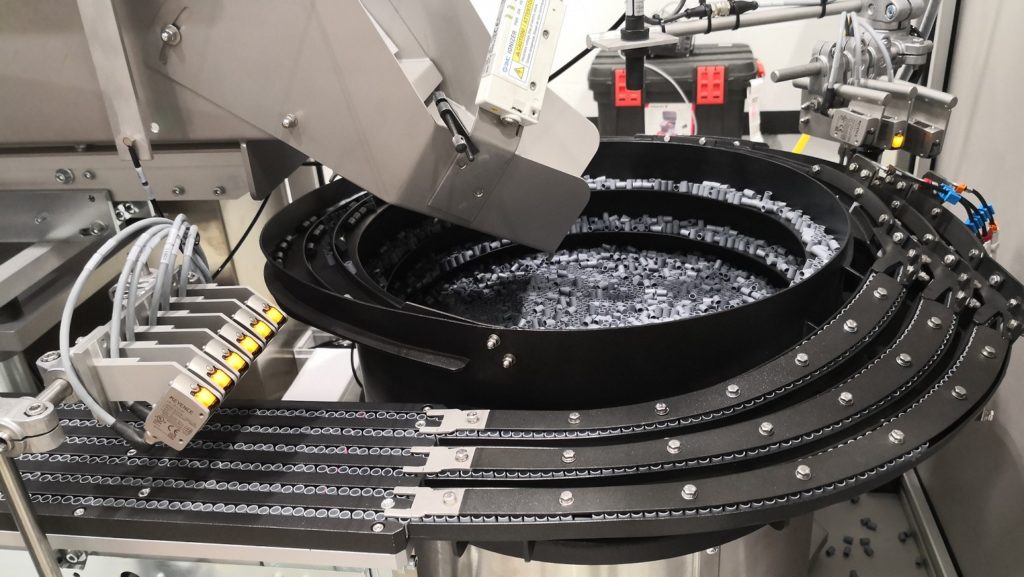

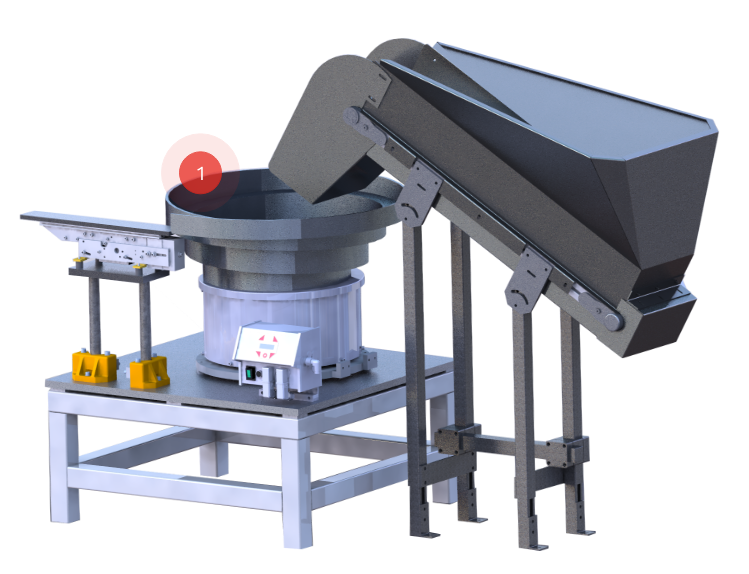

Vibratory bowl feeders are the most common part-feeding devices used in industrial assembly automation. They are self-contained systems consisting of a specially tooled bowl that orients components, a vibrating drive unit on which the bowl is mounted, and a variable-amplitude control box.

How does a bowl feeder work?

The bowl feeder, often including an outfeed accumulation track to convey and discharge parts into an assembly machine, is available in many shapes and sizes. The drive unit—available in electromagnetic or pneumatic versions—vibrates the bowl, causing parts to move up a circular, inclined track. This track is engineered to sort and orient parts into consistent, repeatable positions.

Track length, width, and depth are carefully selected to match the application and component geometry. Special track coatings are applied based on the part’s shape, size, and material to improve traction, prevent product damage, and reduce noise levels. A variable-speed control box regulates the vibration and, using sensors, can start or stop the flow of parts to the outfeed track as needed.

Applications of bowl feeders

Vibratory feeders are used across a wide range of industries, including pharmaceutical and medical, automotive, electronics, industrial components and fasteners, packaging and plastics industries.

They are also utilized in sectors such as glass, foundry, steel, construction, recycling, pulp and paper, and plastics.

Vibratory feeders provide a cost-effective alternative to manual labor, reducing both production time and labor costs. When selecting a feeder, factors such as industry type, application, material properties, and product volume must be carefully considered.

RNA engineers and manufactures some of the most reliable, high-quality vibratory part-feeding systems in the industry, offering low-maintenance, accurate handling solutions for a wide range of materials and applications.

Our experienced project managers oversee the entire production process to ensure quality and performance. If you’re looking for a high-quality vibratory feeder or a special-purpose handling system, please don’t hesitate to contact us by phone, email, or our online inquiry form.

Escapements and Nests

RNA Automation also offers complete feeding and handling solutions, including escapements and nests, to accurately position components for collection by customer handling units. Read More >>

RNA Specialist Range RNA provide standard and custom feeding systems.

Applications

Cylindrical Bowls, Conical Bowls, Stepped Bowls, Polyamide Bowls

RNA drive units offer reliability and endurance. The use of high performance magnets give a continuous high feed rate regardless of the number of parts in the bowl.

RNA provide state of the art controllers for all vibratory drive units. All controllers are CE approved and also available with CSA/UL certification.

Bowl Coatings

Bowl coatings minimise the wear and tear of the bowl, treat the parts more carefully and reduce the running noises. The coating material can be chosen according to the application and parts.

Base Plates

The base plate enables easy mounting of the drive unit to the machine table. The base plate SRG hat integrated fixing devices for the mounting of control units.

Stands and Top Plates

RNA stands and top plates have a large height-regulating range. Due to their finely adjustable regulation, they enable an optimal interface compensation at the part discharge points.

Sound Covers

Reduce noise and protect against dust

Contact

Send your message to a member of our team

Read our Privacy Policy to learn how we manage and protect your submitted information.