Solution

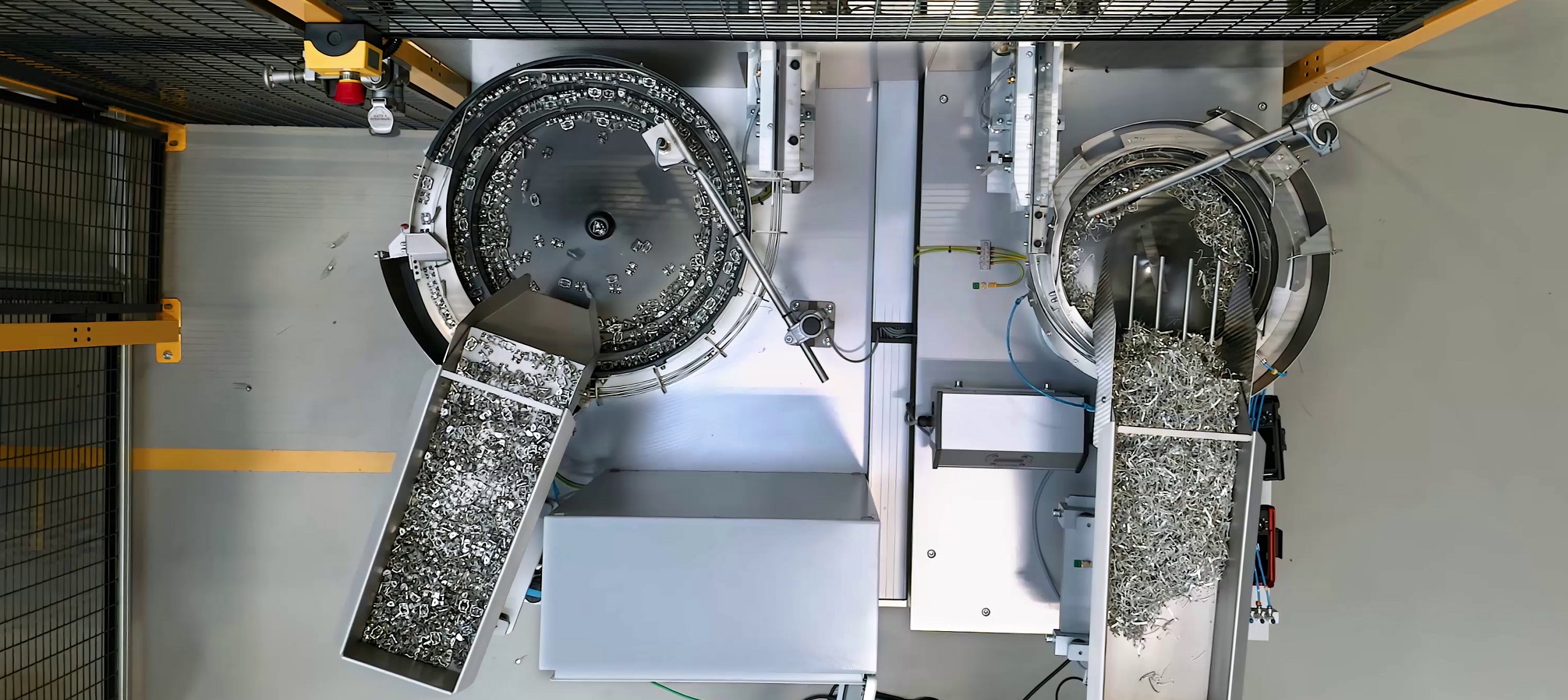

This case study covers two vibratory bowl feeders used in an insert molding cell to automate part delivery for the insert molding process.

Bulk Storage Hoppers

Bulk storage hoppers are used to store components and feed them into the vibratory bowl feeders.

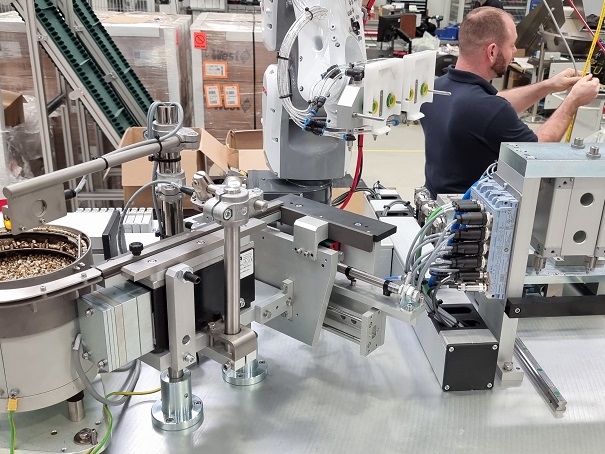

Bowl Feeder System – Electrical Contact

The vibratory bowl feeder sorts and feeds electrical contacts, pins down, into a single-file linear outfeed track. At the end of the linear track, a pneumatic escapement separates two electrical contacts for robot pickup. A vision sensor mounted above the escapement checks picked parts for bent pins.

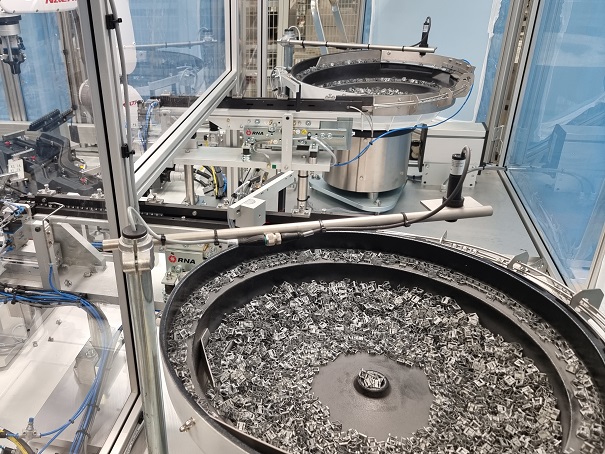

Bowl Feeder System – Metal Insert (Metal moulded part)

The vibratory bowl feeder orients and feeds the inserts, end to end, flat face angled away from bowl at 28.7°, into a single-file linear outfeed track. At the end of the linear track, an electric escapement separates four metal inserts for pickup by the load robot.

Bulk Storage Hoppers

Bulk Storage Hoppers

Insert Bowl Feeder

Insert Bowl Feeder

Electrical Contact Bowl Feeder

Electrical Contact Bowl Feeder