Tailored Engineering

Custom-built solutions designed to integrate seamlessly into your equipment and production line.AI & Simulation Expertise

Our advanced AI-driven simulations optimize system design and performance, ensuring precise part handling and maximum efficiency.Industry Expertise

Trusted by OEMs for decades, with extensive experience in feeding and handling automation.High-Quality Build

Robust, precision-engineered systems built for durability, reliability, and long-term performance.Comprehensive Support Services

From initial consultation to ongoing maintenance, RNA provides full-cycle support to ensure smooth integration and sustained operational success.Long-Term Partnership and Consultation

We collaborate closely with OEMs as strategic partners, offering continuous insights and recommendations for ongoing improvement and innovation.Discover RNA Feeding & Handling Technologies

Our cutting-edge feeding and handling systems, advanced AI-driven simulations, and custom-engineered designs optimize your production processes—helping you meet the demands and challenges of modern manufacturing with precision, efficiency, and reliability.

Our Process: How RNA Delivers Your Solution

We partner with OEMs to deliver custom feeding and handling solutions. From concept to commissioning, we work closely with your engineering team to design and implement high-performance systems that minimize downtime, increase throughput, and integrate seamlessly with your equipment.

RNA’s Industry Expertise

With decades of experience and a strong commitment to innovation, we partner with OEMs across multiple industries to deliver reliable, custom-engineered systems that enhance efficiency, reduce waste, and drive long-term success. Whether you’re developing new equipment or upgrading existing production lines, RNA is your trusted automation partner—providing scalable, future-ready solutions designed to evolve with your business.

Applications

RNA Capabilities for OEMs

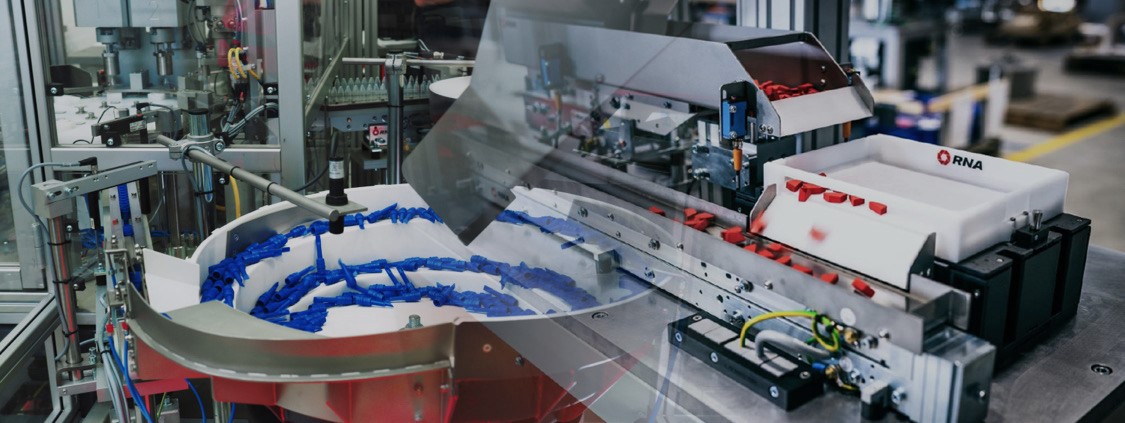

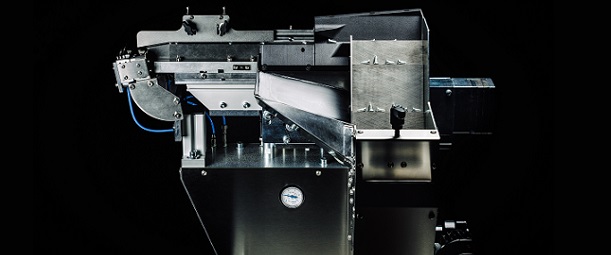

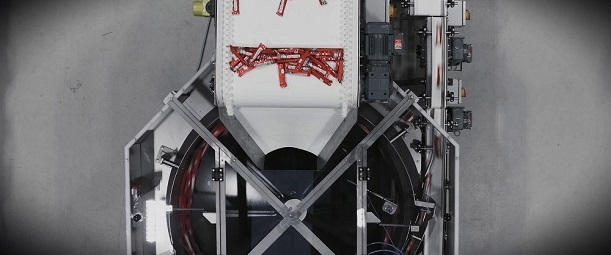

- Custom Feeding & Handling Systems – Design and manufacture of custom bowl feeders, linear feeders, and part orientation systems tailored to integrate seamlessly with OEM machinery.

- AI & Simulation Tools – Using advanced AI and simulation tools (RNA Digital), RNA optimizes system designs for performance, reliability, and efficiency—predicting part-handling outcomes and reducing development time for OEM applications.

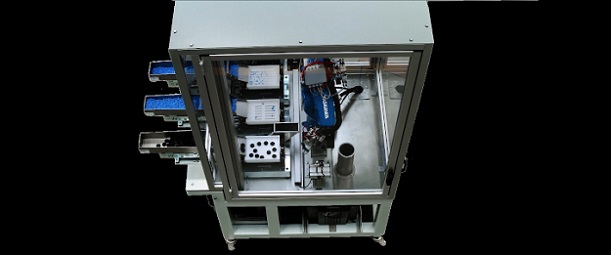

- In-House Manufacturing & Assembly – Complete control over production quality through in-house fabrication, precision machining, and assembly of all systems.

- Electrical & Software Engineering – Design and development of control panels, PLC/HMI programming, and communication interfaces for fully integrated, turnkey automation.

- Prototype Development & Testing – Rapid prototyping and in-house Factory Acceptance Testing (FAT) using customer parts to ensure optimal system performance and reliability before delivery.

OEMs FAQs

RNA provides a wide range of solutions, including vibratory bowl feeders, linear feeders, centrifugal feeders, step feeders, and robotic handling systems—all designed for integration into OEM equipment.

Yes, all our solutions are tailored to meet your unique requirements, ensuring compatibility with your existing lines and specific part-handling needs.

We work closely with your engineering team from initial concept through commissioning, providing design support, CAD models, simulations, and on-site assistance.

Our solutions are fully compatible with robotic pick-and-place systems, vision inspection, and other automation technologies.

OEMs benefit from reduced development time, proven reliability, precise handling, and long-term technical support — all contributing to enhanced end-customer satisfaction.

Yes, we provide comprehensive after-sales service, maintenance support, and a full range of spare parts to ensure long-term system performance.

Lead times vary depending on complexity and customization, but we aim for an efficient turnaround with clear project timelines provided upfront.

We conduct thorough product analysis and testing to ensure each system is optimized for part geometry, material, and speed requirements—minimizing wear or damage.

Yes, our systems are engineered for high efficiency and throughput, making them ideal for demanding production environments.